In recent years, foam products have begun to be used in all spheres of human life. Most often they are used in construction, and not only as insulation. For example, decorative elements in the form of ceiling skirting boards and tiles made from this material are popular. Since polystyrene foam is produced exclusively in white, many buyers think that it is not suitable for decorating their interior. Luckily, there are ways to paint foam board and give it a look that matches the overall decor of the room.

Advantages of painted material

Polystyrene foam is a very popular material in construction; it is used for both external and internal work. However, after some time it may lose its attractive appearance. In addition, the initially white decor may not match the color scheme of the room. These reasons force craftsmen to paint materials in a shade suitable for the interior.

Due to the fact that some compounds can destroy the structure of polystyrene foam, before starting work it is important to figure out what paint to paint it with. Foam plastic will retain its attractive appearance for a long time if this work is done correctly. In this state it will have more advantages:

- it will be protected from moisture, dust, grease stains and other aggressive influences;

- polystyrene foam that turns yellow over time will not become noticeable under a layer of paint;

- painting will make everyday care easier;

- the decor will harmoniously fit into the design of the premises.

How to paint a concrete floor with polystyrene foam varnish - see in this video:

The material is very light and easy to work with, so it is used by professionals and home craftsmen. It is widely used not only in interior decoration of premises. Elements made of foam plastic often decorate the facades of buildings, gardening areas, and insulate the facades of buildings with slabs. With the use of coloring agents you can realize many original ideas.

A correctly chosen coloring composition can keep structures and decorative items beautiful and attractive for a long time. In this form, they will be less sensitive to sunlight and other destructive factors.

Why paint foam?

Since the natural color of polystyrene foam is white, in its usual form it can fit into very limited interiors. Probably only those decorated in an urban, ultra-modern style. However, since polystyrene foam is a material that has significant advantages due to its convenience, lightness and practicality, it should not be deprived of other interior design areas. In most cases, it is necessary that the material be painted - this way it can best fit into the design of the room.

In addition, foam itself is not a very durable material. To make it more resistant to external conditions, including high humidity, it is best to paint it. A layer of paint serves as protection for fragile tiles, cornices or baguettes, protecting them from external adverse influences.

Often unprotected, “bare” foam plastic can turn yellow, and it is also afraid of wet rooms, so painting foam ceiling tiles, like other interior parts made of this material, is the best solution in most cases. This way the material will last much longer.

For foam baseboards, however, as in cases where they are made of wood, painting is sometimes the only way to achieve a solid look. Often, after installing skirting boards, unsightly joints form. They can only be removed with putty and subsequent painting around the entire perimeter.

Paint selection criteria

Foam products are sensitive to paints and varnishes. For this reason, you should carefully consider how to paint polystyrene foam so that it retains its appearance for a long time. Since this material does not tolerate acetone and other solvents, experts advise choosing water-based products. Such coatings are called water-dispersion. They can be:

Since foam does not tolerate solvents, the paint must be acrylic or water-based

- water-based;

- acrylic.

Any type of paint must meet basic requirements:

- it should fit well on the work surface;

- have high density and water resistance;

- be resistant to chemical influences.

All these parameters must correspond to the operating conditions of foam products.

However, not all foam items can be painted. The restriction applies, for example, to laminated plastic ceiling tiles. It just needs to be installed correctly, and it does not need painting.

Exterior painting

Painting the outside of foam requires weather-resistant paints.

The walls of a building are affected by temperature fluctuations and precipitation, so paint for polystyrene foam must be flexible and not lose its qualities for a long time.

Before you start painting, you need to do some preparation. Acrylic compositions are more suitable for outdoor work, since they are highly resistant to environmental factors.

Before painting, it is necessary to putty the joints. Then experts recommend applying a primer and removing any unevenness after it dries. The paint is thoroughly stirred and brought to a uniform state and color.

The paint can be applied with a brush or roller in one direction. If necessary, use an aerosol.

Painting extruded polystyrene foam on the facade of a building consists of several preparatory stages:

- the surface is leveled (including the locations of the dowels), the joints are made invisible;

- cleaned of dirt and dust (for better adhesion of the primer);

- primed with an acrylic compound, the resulting drips are removed with a spatula.

After giving the paint the required shade, it is poured into the bath. To apply a decorative coating to the walls, use a roller, moving it in one direction (from bottom to top) to prevent the formation of streaks.

After waiting for one layer to dry, apply a second one. Often, when finishing facades, a layer of plaster is applied to the foam plastic. Before starting treatment, façade paints must be mixed well.

If the ambient temperature is below 15°C, it is recommended to use waterproof materials, since as the humidity level increases, the quality of the coating deteriorates. When applying the acrylic composition in a thick layer, bubbles may appear.

Characteristics of coloring compositions

The range of coloring products is quite large. According to experts, it doesn’t matter what kind of paint you use to paint the foam, as long as it is water-based. This is due to the fact that the type of polymer almost does not reflect its properties. However, in order for the painting to be done efficiently, you should know the advantages and disadvantages of the compositions used.

The best paint option for polystyrene foam is acrylic.

Among the water-dispersed group of paints, acrylic paint has performed very well. This coating has the following positive properties:

- reliable protection against ultraviolet radiation;

- long service life;

- dries quickly and has no odor;

- health safety;

- ease of application;

- easy to clean if necessary;

- resistance to pollution;

- the composition is not affected by high temperature;

- a wide variety of shades.

Painted foam is easy to clean

In addition to the listed advantages, this coloring material has the only drawback - it is high cost. However, it is fully justified by significant advantages. A high-quality composition cannot be too cheap.

In addition to acrylic paints, you should pay attention to water-based coatings. They also have good properties. Among the advantages:

- environmental friendliness;

- lays down smoothly and has no odor;

- good vapor permeability;

- large color palette;

- average cost.

The qualitative characteristics of this coating are inferior to the acrylic composition. It has several significant disadvantages. The paint has low resistance to stains and does not tolerate moisture well. Over time, its surface is washed off with water. If you apply it in large quantities, it may peel off. However, despite all these disadvantages, water-based emulsion is quite in demand among consumers.

The advantages and disadvantages of coloring agents will help you decide which paint is best to paint polystyrene foam.

What to paint

Construction foam is deservedly considered one of the most versatile materials. It is used for insulation, cladding and as a material for the manufacture of most decorative elements.

At the same time, due to its low cost, products made from it have an affordable price:

- Ceiling tiles based on polystyrene foam are an excellent choice as a finishing material for the ceiling, providing an aesthetic appearance and not requiring major investments. It is not afraid of water, so it can be installed in rooms with high humidity, such as a kitchen or bathroom, but unprotected foam itself is very fragile and can be easily damaged even by accident with bare hands. In addition, under the influence of direct sunlight, such tiles will certainly fade and acquire a yellowish tint.

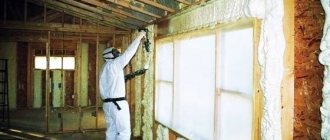

- Also, foam panels are one of the most popular and widespread options for organizing thermal insulation of the walls of residential buildings. As a rule, they cover the outer parts of the house, its facade, which, unlike the premises inside the building, is constantly exposed to the negative influence of nature in the form of frost, ultraviolet radiation, and precipitation. Therefore, such a coating, which has a relatively fragile structure, requires not only careful handling during installation, but protection in the form of a paint coating for the period of operation.

- Today, very often for interior decoration, skirting boards are used for the ceiling, made on the basis of foam plastic. When purchasing, the color of such a decorative element is usually white. But often it is not the most suitable for a particular interior, and almost always the uncoated material is not very practical. Therefore, in some cases there is a need to change its shade to something other than white. In addition, sometimes the surface of such a plinth has defects, which can be especially visible after installation, when the light in the room is on. In this case, painting is the only alternative to redoing all the finishing work and replacing the baseboard. It will not only mask imperfections, but also add strength to decorative elements. One of the features of the plinth that is conducive to painting it is that during its installation, joints are formed between its different parts, which have to be primed with putty, and in order to hide all traces at the final stage, the plinth is covered with paint along the entire perimeter. Sometimes the need for painting arises suddenly, some time after installation, for example, after a roof leak, when stains appear on the white decor that cannot be cleaned. Then either buy and replace decorative elements, or paint everything and forget.

Indoor work

The process of coloring foam products consists of several stages. Before you paint the foam, you need to prepare it. A primer is used for this. An aerosol composition is best suited for this purpose; it is simple and easy to apply to the desired object, the surface dries quickly and can be ready for subsequent work in a short time. This product is ideal for priming the desired element indoors.

Before you start painting parts, you need to prime them with an aerosol composition.

At the very beginning of work, you need to clean the surface with a damp cloth and wait until it is completely dry. When using an aerosol primer, it is recommended to shake the bottle for a few minutes before application and then coat the material with it.

The composition is sprayed quickly, applying a thin layer at a distance of 20 cm from the product. 3-5 layers of primer are enough to get a high-quality coating. After this, the material must dry completely. This takes approximately 30-30 minutes. Various irregularities or drips can be removed with a spatula, lightly touching the surface.

How and with what do you prime and paint polystyrene foam?

Rating 4.40 (10 Votes)

| Foam plastic is perhaps one of those types of materials that provides wide scope for creativity, allowing you to implement the most non-standard design solutions. Decorative products and structures, interior items, elements of building facades, garden sculptures - all this can be made from foam plastic. Today, architectural and decorative designers often use lightweight and durable foam plastic along with traditional materials such as plaster, marble, and stone. |

A creative approach and a couple of extraordinary ideas will help you create many original objects and designs from polystyrene foam. Sometimes simple shapes and a few color accents can be the icing on the cake in your interior design.

If we talk about decoration, since not every decorative material (primer, paint, varnish) will be compatible with a foam product, pertinent questions arise: How to process foam plastic? How and with what to paint it? Do I need to prime the foam and with what means? We tried to answer these questions and prepared some useful tips for you.

| What do you need to prime and paint foam board at home? - Soil. A special primer for polystyrene foam is ideal. - Dye. For decorative work, it is better to use aerosol paints for polystyrene foam or water-based acrylic paints packaged in jars and tubes, which do not contain solvents dangerous to foam plastic. - Varnish. Needed for additional surface coverage and protection of the material from external influences. It is important to use a universal water-based varnish. — Brushes, rollers and sponges for decoration |

— Paper tape (painting tape)

— Gloves, goggles/mask or painting kit

- Newspapers, film for covering surfaces, plastic sheet - any material that can protect the work surface during work.

— A container of water, cotton rags (cloths for cleaning), detergent.

— Acetone or white spirit for cleaning the work surface (NOT for foam products!)

.

| Materials for priming and painting foam products Before turning your creative ideas into reality, you need to carefully select materials and prepare the foam for work. An important step is the primer. An aerosol primer for foam plastic is very convenient; it is easy to apply, fits well on the surface, and dries quickly. This primer can be safely used for interior work. The choice of paint for foam plastic should be approached as responsibly as possible. Important to remember! Expanded polystyrene is absolutely not resistant to solvents. Therefore, avoid the following substances: acetone, white spirit in the composition, etc. Choose water-based paints. |

The ideal paint option is water-based aerosol. A wide palette of bright, saturated colors, the pigment of which is very durable. It is important that this paint is non-toxic, practically odorless, it is absolutely safe, so it can be used indoors. This paint is suitable for any surface, including foam.

| If your future product needs to be especially bright and expressive, choose fluorescent paint for graffiti. This is a durable, highly pigmented acrylic paint. The advantage of this paint is that it fits perfectly on a variety of surfaces, and is not at all dangerous for fragile foam plastic. Do you want to paint a product with a brush? Water-based acrylic paints in jars or tubes are perfect for this. The palette of such paints is rich in color shades that can be used not only for painting the surface, but also for applying designs. Working with acrylic paints is not difficult, but always check the instructions to take into account all the nuances. |

Step by step instructions

| Foam primer: Step 1 Clean the surface to be decorated with a damp cloth or sponge and wait until dry. Step 2 If you are using a spray foam primer, shake it well for about a minute. Spray with quick movements, holding the can vertically. Apply a thin layer at a distance of 20 cm from the surface. To achieve perfect coverage, it is advisable to apply 3-5 layers at intervals of 5-10 minutes. Paint all areas thoroughly and avoid the appearance of pores. The aerosol primer only needs 30-40 minutes until it dries completely, after which you can apply paint. |

IMPORTANT!!!

Laminated and extruded polystyrene foam requires special processing. First you need to sand the surface to make it rough. After this, the surface must be coated with a special adhesive primer (primer).

Step 3 If there are small streaks or dried drops left after the primer, just go over it lightly with a spatula to remove all the unevenness.

| Painting foam: Step 1 Prepare paint and all necessary tools. If you use aerosol paint to paint foam plastic, then before starting work you need to shake the can thoroughly for 1-2 minutes. You should hear a clear sound from the metal balls inside, then the paint is ready to go. Try to spray the paint evenly, the movements should be back and forth at a distance of 30 cm from the surface. Apply paint in 2-3 layers. Important! One coat takes at least 30 minutes to dry! After one layer has dried, you can safely apply the next one. This is perhaps the only difficulty; otherwise, working with aerosol paints is easy and convenient. |

Step 2 If you decide to paint the foam using a brush with acrylic paint from a jar or tube, then follow several rules. Mix the paint thoroughly before applying to the surface. To change the consistency or color of the paint, add water to it and mix well. The brush should be washed before each use of a new color.

Step 3 You can additionally seal the painted surface with varnish. Choose a specialized water-based varnish for this. You can safely use it to protect the surface of foam plastic painted with water-based acrylic paints.

| What should you pay attention to when painting foam? 1 To ensure that there are no streaks on the surface of the foam when painting, you must always move the brush in one direction. 2 If you suddenly purchased paint that contains solvents that are dangerous to foam plastic, then you can use a layer of ordinary plaster to protect the surface. This isolates the corrosive substances from the material. |

3 The paints and varnishes used must have a high adhesion coefficient (to Penoplex and PSB), it is good if the paints are resistant to atmospheric influences and odorless.

4 Coloring is best done at low humidity and an air temperature of at least 15 degrees.

5 If you work with paint from jars or tubes, it is useful to have a flat brush 4-5 mm wide in your arsenal. And for painting small details - a thin round brush.

6 Acrylic paints must be applied in a thin layer. If the layer is too thick, the coating will bubble when applied and will peel off after drying.

We tried to tell you about the most important points that you need to know when working with polystyrene foam. In fact, working with this material is not difficult, but you need to pay attention to the details. We wish you creative inspiration!

| Ideas: how to use polystyrene foam in decoration ♣ A foam panel will become a stylish addition to the interior. ♣ Children's room, advertiser's office, beauty studio, etc. can be decorated with bright, voluminous letters, large or small. It all depends only on your imagination. ♣ Figurines, New Year's toys, as well as small bright foam structures will become excellent decorative items during the holiday and beyond. |

Visitors to this page most often choose from the online store:

Aerosol primer for foam plastic 400 ml"

|

Sequence of actions during operation

To paint the outside and inside, select the desired type of composition. After choosing, you can start painting the product yourself. The easiest way to do this is to use a product in an aerosol package.

To paint polystyrene foam with your own hands, it is best to choose spray paint

Before starting work, shake the can for 1-2 minutes and then evenly cover the surface from a distance of 30 cm in 2-3 layers. Each time it must dry and only then can the next layer be applied. This method is considered the simplest if you learn how to work with a cylinder.

If the composition in a jar is used, painting is done using a brush or roller. The required amount of water is added to the paint to achieve a suitable consistency. If several tones are used, the composition should be mixed well before coating to obtain an even color. If the elements are painted in different colors, then the brush must be rinsed well with water each time.

To consolidate the result, you can use varnish. A special water-based varnish is often used in combination with acrylic paint to further protect the surface of the foam.

Stages of work

A step-by-step work diagram is presented using the example of painting the facade of a building. In this case, all existing nuances and aspects will be affected, since the facade is regularly exposed to ultraviolet rays, precipitation and temperature changes in spring and autumn.

After the panels are fixed to the outside of the walls, you can begin to work, namely, to create a high-quality base for paint. The following work steps must be completed:

- surface leveling. It is necessary to make the existing joints as invisible as possible, and also to level the areas where the dowels were located;

- cleaning It is necessary to remove accumulated dust and dirt from the surface. Otherwise, the adhesive properties of the soil composition will be lower than expected;

- primer. For this you can use a regular acrylic composition. The primer is poorly absorbed into the surface of the panels, so during the work, characteristic smudges may form, which will subsequently need to be removed with a spatula, otherwise, when creating a decorative coating, the paint will repeat the relief of all the formed drops.

Preliminary work allows you to create a durable and uniform surface without protrusions and gaps. Once all steps have been followed, you can begin painting. The process itself is quite easy. If you have the necessary tools, it can be performed by a person without the appropriate education.

Additional painting tips

To avoid leaving streaks on the foam, move the brush in one direction. The purchased material for painting must have a high adhesion coefficient. In this case, it will easily lie on the material.

To paint foam plastic, you need to have two brushes, wide and thin.

If the paint contains solvents that are hazardous to polystyrene foam, then a layer of plaster should be applied to the surface to be treated. It will serve as protection against destruction.

For better quality painting, it is better to have two brushes: a flat one 4-5 cm wide and a thin round one for processing small details.

When working outdoors, paint should not be used if the temperature drops below +15 o C. The quality of the coating will be negatively affected by high humidity. It is advisable to use only waterproof material.

Acrylic paint cannot be used in low temperatures and high humidity.

Acrylic compounds tend to bubble if they are applied in a thick layer. Over time it will begin to fall off. Experts recommend using paints that are completely ready for painting. They will make the work easier for those who do not have the necessary experience in this matter and will help to obtain a high-quality result.

The process of painting foam plastic has many subtleties and pitfalls. However, following these tips, a home craftsman will be able to carry out painting efficiently and quickly.

Cutting foam plastic - what could be easier? After all, ease of processing is one of the main advantages of this material. But in the end it all depends on your goals. What is important here is the amount of work, the thickness of the slabs used, and, of course, the complexity of the cut itself. I want to introduce you to all the tools used in this area, some of which are only suitable for industrial use, while others you can easily use at home.

Painting foam

In most cases, paints based on water emulsion and acrylic suspension are used for painting foam plastic. The choice of one type of paint or another depends on the location of the foam materials: inside or outside the building.

Inside the building

Inside the building, water-based paints and varnishes are almost always used. They are characterized by low cost, about 25-40 rubles per liter, but are unable to withstand moisture and heavy dust, which determined their specific use only for indoor spaces.

When applying such paint to the interior decorative elements of a room, the optimal viscosity of the paint is ensured, allowing you to hide the pores in the material under a uniform layer of coating. Before painting ceiling tiles, moldings, baseboards and rosette decorations, it is recommended to wipe them from cobwebs and dust with a dry cloth.

Painting is usually done with a brush and roller. However, in the case of painting decorative elements with a thin and intricate relief, not a brush is used, but a spray gun, which allows you to quickly apply a uniform layer of coloring pigment to the material. To avoid paint getting on the wallpaper, it is best to paint the moldings and foam cornices before installing them.

Outside the building

On the outside, acrylic-based solutions are used, which are highly resistant to the influence of aggressive external environments, but they are much more expensive - from 50 to 50 rubles and are not durable. That is, they need to be updated from time to time.

For the use of paints as a coating for polystyrene foam boards that provide thermal insulation for the external walls of a house, the characteristics of increased elasticity, resistance to precipitation and contrasting temperature changes are very important.

This composition is first diluted with water or a primer, due to which it acquires increased elasticity. Thorough mixing is required until a homogeneous consistency without lumps is required.

Another protective coating option for polystyrene materials is a thin layer of putty, after drying, which can be painted with any paint containing acid.

Nowadays, when decorating premises, such a convenient, lightweight and inexpensive material as polystyrene foam is often used. Cornices, various elements, baguettes, picture frames, baseboards, segments of ceiling tiles, and various decorative details, for example, large interior letters, are made from it. Since the natural color of polystyrene foam is white, it often becomes necessary to paint it. In this article we will tell you how to paint polystyrene foam yourself at home.

A little about the material itself

Before moving directly to the most important thing, I want to devote a few words to foam plastic. Essentially, this material is foamed plastic, a set of thin-walled plastic vessels filled with air. The description is very exaggerated, but it very clearly conveys its device and the presence of technical characteristics associated with it.

The cellular structure is very easy to see even with the naked eye

What is the problem with cutting?

In the photo above, the tiny fragments that make up the foam board are clearly visible, and you can even see that in some places they have already flown off. This is where the difficulties associated with even cutting of this material lie: fragility. It easily crumbles or even breaks completely when in contact with various tools or even just bare hands.

The slab can turn into crumbs very quickly

Thus, during the cutting process, it is necessary to achieve such a result that the tool passes through the foam with minimal resistance, without causing destruction of its structure.

Density is important

In addition to the technology that you choose to implement your plan, an important factor is also the density of the foam, which is easily determined by the markings applied to it:

- PSB-S-15. The cheapest and most fragile brand , which is used exclusively as a thermal insulation material placed behind decorative trim. Technical data:

| Characteristic | Meaning |

| Density | 10.15 kg/m3 |

| Compressive strength | 0.05 MPa |

| Flexural strength | 0.07 MPa |

| Coefficient of thermal conductivity | 0.037 W/(m×K) |

This is what the markings on purchased foam sections may look like

- PSB-S-25. The most popular option when carrying out finishing work, as it is still incredibly cheap, but at the same time has higher strength characteristics that simplify its operation. Technical data:

| Characteristic | Meaning |

| Density | 15.25 kg/m3 |

| Compressive strength | 0.1 MPa |

| Flexural strength | 0.18 MPa |

| Coefficient of thermal conductivity | 0.035 W/(m×K) |

Example of marking PSB-S-25

- PSB-S-35. These samples can withstand physical impacts much better, which is why they are widely used in the construction of swimming pools, sports fields, lawns and insulation of foundations. Accordingly, their cutting is easier with less waste. Technical data:

| Characteristic | Meaning |

| Density | 25.35 kg/m3 |

| Compressive strength | 0.16 MPa |

| Flexural strength | 0.25 MPa |

| Coefficient of thermal conductivity | 0.033 W/(m×K) |

Sample of applied marking PSB-S-35

- PSB-S-50. This brand has the highest density , which allows you to create the most complex artistic figures from it with your own hands, even with simple tools.

PSB-S-50 - the most durable foam boards

Thus, the first thing to do to prevent foam from crumbling is to choose a product of the appropriate brand. Although, of course, if the quality of the cut does not matter in your situation, then there is no need to overpay for strength.

Tool No. 2: stationery knife

An ordinary paper cutting knife can also cope with the task.

If you don’t have a shoe knife at hand, and you urgently need to divide the section into given sections, then use a basic stationery tool designed for cutting paper sheets . All the problems listed above are also valid here, only instead of sharpening you should simply break off the blades, which in case of large volumes of work will lead to significant consumption.

If the cutting blade is heated, it will slightly melt the plastic foam capsules, which in turn will significantly facilitate the movement of the blade. By the way, the use of high-tech cutting methods for the material in question is based on this feature, but more on them below.

Diagram showing the difference between using a cold and heated blade

Tool No. 3: hacksaw

Hello, a hacksaw suitable for the implementation of the plan

How to cut polystyrene foam at home if its thickness exceeds 40 mm? The simplest answer in this case: a hacksaw . But I’ll immediately note that this tool is not universal, as it is only suitable for creating straight edges.

Try to look for a saw with the thinnest teeth, as they are less likely to catch plastic vessels when passing between them, which as a result has a beneficial effect on the quality of the cut.

Tool No. 4: “grinder”

Angle grinding machine

The eternal companion of builders and mechanics, the “grinder”, is also used for cutting foam plastic. The main thing is to choose the thinnest metal circles to complete the task.

But, frankly speaking, I don’t really like this option, I’ll justify it:

- The squeal of foam interacting with the angle grinder wheel is also accompanied by the noise of the motor of the power tool itself . Here even headphones may not save your mood;

- Everything, literally everything, will end up in foam chips , so cleaning will then be quite lengthy;

- Electrical energy consumption will be added , which will then have to be paid.

A plus is that the grinder cuts the material for you. But this is true for metal, which is really difficult to cut with your own hands with just a hacksaw, while foam plastic practically does not resist under the influence of the listed tools.

Tool No. 5: laser machine

Example of a laser machine

If you need to not only insulate walls, ceilings or floors, but also create a complex advertising sign, decorations for a theatrical performance or architectural elements of an unusual shape, then it is best to turn to professionals who have special laser equipment, which, using their software, can carry out precise three-dimensional cutting of foam plastic.

Need a car mockup? Easily!

That is, in fact, the foam section can be given any shape at all. This already brings the process to the level of artistic art.

But there are also plenty of problems with this technology:

- The equipment itself is incredibly expensive , and its operation is possible only by specially trained operators;

- Ordering the right project will also be expensive for your family budget , so before making the final decision, carefully consider everything.

What kind of paint is used for foam?

Choosing the right paint for polystyrene foam involves choosing the right composition. Paint for foam plastic must meet the following requirements:

- Water resistance.

- Density.

- Resistance to external factors.

- Elasticity.

- Adhesion.

Foam boards

Various dyes are used to process the material. The most commonly used coloring materials include acrylic or water-based suspensions. Other types of paints do not cover polystyrene foam because of the corrosive substances they contain: alcohol, acetone or white spirit - they have a destructive effect on polystyrene foam. To paint foam boards, you need special paints and varnishes that are not afraid of temperature changes and water.

It is worth noting that before spray painting the foam, you must first apply a protective layer to the surface. “Liquid glass” is most often used as a protective layer. Before application, “liquid glass” must be diluted; for this, a primer and, less often, water are used. The first option gives the best effect - the surface is covered better and the pores of the material are eliminated. Liquid putty is also used as a protective layer.

Polystyrene foam, which is covered in several layers, forms a special protective crust, and the product itself acquires a glossy finish. After complete drying, the material is ready for painting.

Algorithm for painting different foam surfaces

Having familiarized yourself with the compositions of how to paint polystyrene foam, you can begin the procedure. All work on painting foam surfaces must be carried out in strict sequence.

The ceiling molding needs to be painted, having previously sealed the joints with mounting tape Source build-experts.ru

- At the initial stage, level the surface. To do this, hide the seams using putty or a special adhesive. It is also necessary to smooth out the places where the dowel heads stick out (if this is a façade covering). In addition to solutions, reinforcing tape can come to the rescue.

- Do not start painting until you have removed dust, dirt, cobwebs and excess roughness from the foam. When painting foam plastic, they will roll off and spoil the appearance. This will result in dirty spots, pellets and other defects.

- Perform priming. To do this, use a special acrylic-based composition. During the process, the primer may roll off, so smudges cannot be avoided. This is not a problem, since after the product has completely dried, all protruding elements can be carefully removed with a spatula.

- Putty the foam surface after applying the primer. This will make it possible to maintain the strength of the coating when in contact with aggressive paintwork materials. For putty, use a rubber spatula, trying not to leave indentations or scratches (although they can be removed later by sanding). The entire surface does not need to be puttied if water-dispersed paints are used. It is enough just to hide the joints.

- Carry out painting according to the intended scheme, use a roller. With its help, any type of paint will apply smoothly and neatly. Don't forget to have a small brush. It will help paint over small, hard-to-reach places (in corners, for example). Pour some paint into the tray and then dip the roller. Make sure it doesn't drip. When coating the surface, move strictly in one direction, otherwise streaks will appear.

How to treat foam before painting?

To ensure high-quality painting work, it is necessary to carry out a number of preparatory measures. There are three mandatory steps, without which the surface will not be painted well:

- The first step is to completely clean the material, that is, dust and existing contaminants must be completely removed from the surface of the foam boards. To do this, the material must be rinsed under running water or, if this is not possible, thoroughly wiped with a clean damp cloth. Do not rush and immediately cover it with paint. The slabs must be completely dry, otherwise even waterproof paints will not stick to the surface.

- The second important point, which is a component of high-quality coating of a material with special coloring agents, is the direction of paint application. For uniform application and a beautiful layer as a result, the paint must be applied with a special brush and adhere to one direction of application. Thus, after the layer dries there will be no streaks left on the surface.

- In order for the paint to lay evenly and the surface to have a presentable appearance, and for the material to retain its quality characteristics for a long time, it is necessary to apply the paint twice, allowing each layer to dry completely.

Preparing paint for foam plastic

Models of professional paints for foam plastic

There are plenty of coloring agents with suitable composition. We offer several interesting compounds that are completely harmless to polystyrene foam.

- Tikkurila luja. An ideal paint option with different characteristics. Differs in covering properties. This is the ability of paint to hide the shade that was originally presented on the surface of the foam. The lower this indicator, the more layers will have to be applied to hide the base.

- Parade W4 - foam paint is quite durable, adheres well to the foam and stays on its surface. Tikkurila Euro 7 is the best option for polystyrene foam. Suitable for decorating fillets, moldings, baguettes. Such paintwork materials are often used to decorate baguette designs or ceiling patterns on tiles.

- Acrylic glazers are necessary to create a decorative effect: aged stone, malachite, imitation wood coatings, marble, silver and other artificial coatings.

On a note! Before applying paint, use a primer regardless of what function the foam will serve: toy, facade, decoration. It is advisable to prime the coating in two layers.

In case extruded polystyrene foam needs painting, then an initial treatment with an adhesive primer should be performed.

Painting foam crafts with oil paints Source dekormyhome.ru

Work technology

Acrylic-based paints are used for exterior decoration. The work technology has the following stages:

- Measures are taken to clean the surface from dirt or dust.

- The joints of the plates are sealed with a special tape (reinforcing).

- The surface of the product is leveled.

- Next, you need to prime the surface with an acrylic compound.

- After this, the paint needs to be tinted.

- Next, the necessary tools are prepared.

Each point is discussed in more detail below:

- After the foam sheets are securely fastened, it is necessary to thoroughly clean them from any dust and dirt present on them. Then leave the cleaned surface for some time until completely dry. Next, you should go over the surface with a primer (acrylic). It is very important to putty the sheets after drying to remove any streaks of primer. You should not skip this point, as otherwise the surface after painting will be uneven and will retain all inclusions or drops.

- After the preparatory work, you can start painting; for this you will need brushes, a roller and a paint tray.

- The coloring material is placed in the bath for convenience.

- Using a roller, paint is applied to the foam sheets. It is advisable to stick to one direction to avoid divorces.

- After applying the first layer, leave it until completely dry and apply the second layer as the next step. If the color after drying is not as saturated as planned, then you can paint it one more time.

The use of acrylic paints makes the material more durable and durable. Thus, the process of insulating the building is simplified, besides, it is profitable and convenient.

Features of painting Hand-Made crafts

The most convenient option for painting polystyrene foam, which is the basis of crafts, is aerosol paints. Only as a base can the workpiece be coated with water-based emulsion. It will be a good start for painting.

Crafts made from pure white foam plastic can be painted with azure watercolor Source roomester.ru

Apply a layer of water-based emulsion to the product on all sides (using paint and watercolor brushes) and leave until completely dry. Next, you can apply a drawing and paint it with gouache along the intended contour. If, for example, you are making a New Year's toy, then you can additionally spray it with aerosol paint with glitter. At the same time, choose odorless synthetic materials.