- Cold welding of linoleum: simplicity and efficiency

- How to glue linoleum together: methods of soldering the material

- Advantages and disadvantages of hot welding linoleum

- Cold welding of linoleum: pros and cons of technology

- Choosing adhesive for joints of linoleum, plastic and metal

- Types of glue for cold welding linoleum

- How to choose the right cold welding for plastic

- Which cold welding is better for aluminum: tips for choosing a composition

- How to use cold welding when laying linoleum

- How to cut linoleum at home and how to do it correctly

- Laying linoleum: how to join sheets before soldering

- Glue consumption for welding linoleum seams and methods of its application

- How to use cold welding for linoleum

- Video: cold welding of linoleum

Cold welding of linoleum: simplicity and efficiency

Cold welding of linoleum allows you to quickly and accurately connect parts of the floor covering. This method of soldering material is so simple that it is easy to use even at home. From this article you can find out what products are used to join linoleum, plastic and aluminum. The text provides a comprehensive overview of the characteristics, advantages and disadvantages of cold welding, as well as guidance on its use.

How to lay linoleum: methods of laying linoleum (read more)

Using cold welding for linoleum, you can quickly and accurately remove damage to the floor covering.

Features of cold welding floor repair

If there are no plans to replace the old linoleum, but there are already tears and cracks on it, you should choose cold welding as a method of repairing the floor covering. This work is easy to do with your own hands.

It is better to choose type C glue for linoleum. This is explained by its thick consistency. This composition is more suitable for connecting linoleum joints than type A glue. It can be used to seal even wide joints. The procedure for sealing cracks in old linoleum is the same as for joining new pieces.

How to glue linoleum together: methods of soldering the material

Linoleum is one of the most popular materials used as flooring. It has both advantages and disadvantages. A significant disadvantage of this material is the presence of seams. They are formed when joining linoleum between adjacent rooms, as well as in cases where it is necessary to cover a large area. On the other hand, modern soldering methods make it possible to easily and quickly deal with this problem without using metal thresholds to mask the seams.

The method of soldering linoleum can be cold or hot.

Before delving into information about how to connect linoleum to each other, it is worth studying the properties and features of this material. This type of flooring is used as finishing in office, residential and industrial premises. The material is easy to install, durable and water-resistant, non-slip and does not require special care. In addition, there is a huge selection of colors and textures on sale. Buyers can even purchase insulated coating options.

The advantages of linoleum also include its size. The material is produced in the form of rolls of various widths. Thanks to this, the buyer can choose the optimal size of linoleum for each room in his home. If you need to lay material in all rooms, then you won’t be able to do without cuts. Moreover, it is not always appropriate to cover the joints of linoleum with metal thresholds or fix the edges of the material with nails. The best option in this case would be to solder the sheets using a hot or cold method.

On a note! Joining linoleum with cold welding adhesive or hot soldering of sheets is ideal for high traffic areas, as well as rooms where the flooring is subject to constant mechanical stress.

Types of gluing

Currently, two gluing options are used:

Cold welding for linoleum.

This is when each part of the coating is laid out according to size in its place and glued. Then they press and glue, with all seriousness, the next line to the previous one in the same way. And so they do until they cover the entire floor surface.

In these cases, colorless glue is used, this makes it possible to make the seams invisible.

Hot welding.

Of course, this is not traditional metal welding, but it is somewhat similar. This method is usually used on an industrial scale. During hot welding, temperature treatment occurs on the edges of linoleum; it occurs at a temperature of four hundred degrees. During processing, a cord is sewn into the middle of the sheet and thanks to this, the materials are held together. As soon as the cord is inserted, the seam is leveled so that it is not visible.

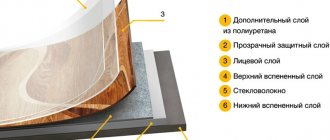

Types of Cold Welding

Cold welding for linoleum is done in various types, which are distinguished by their qualities and method of application.

And so there are three main types:

Cool welding for linoleum type A - has a liquid consistency and contains a solvent, in large quantities, which is needed for processing the edges.

This glue is not used for cracks larger than 2 millimeters.

The main feature of this material is the creation of a beautiful and invisible connection.

This glue also creates a strong and reliable connection, but it is not recommended to use it for repairs.

Cool welding for linoleum type C is an adhesive for cold welding of linoleum, it has a huge amount of PVC material, in other words, it contains less solvent.

Due to the fact that the adhesive composition is rich and juicy, it will easily bridge gaps larger than 2 millimeters.

Cold welding is used to seal cracks that have formed on the old coating. The size of the gaps should not be more than four millimeters.

When the glue dries it leaves a tight, durable seam.

Cool welding for linoleum type T. This type is made for professional use.

This composition is excellent for use with linoleums, which are multicomponent and made on the basis of PVC and polyester.

After applying the glue, the seam is reliable and elastic.

A characteristic feature of the following brands is considered to be a low melting point, however, this option does not require high values, which are found in cold welding for metal.

Advantages and disadvantages of hot welding linoleum

The connection of linoleum sheets by hot welding is carried out due to the effect of temperature. This method is most often used in industrial premises where floors experience serious mechanical stress. The method is also recommended for soldering linoleum in rooms with high traffic, where the coating wears out quickly. It is advisable to use hot seam processing when it is necessary to connect long-term joints.

To connect long-distance joints, it is better to use hot welding.

How to weld linoleum using the hot method?

- For work, a special burner is used, which is called a hot air gun. This tool allows you to melt the material by heating up to 400 °C.

- Before joining the linoleum, you need to prepare the joint area. To do this, use a chisel to select a part of the material along the entire length of the seam so that a groove is formed.

- The welding cord is threaded into the torch, and the device is plugged into the mains.

- To glue the cuts, you need to place the heated filler cord into the groove. This material has almost the same structure as linoleum. The cord is applied with slight pressure, all actions must be careful and very precise.

- Using special scissors, the blades of which have a crescent shape, it is necessary to remove excess glue before it hardens. The cuts are made carefully so that they do not turn out too deep.

- After the molten cord cools, a reliable connection is formed.

- The scar in the junction area must be carefully cleaned.

Advantages of hot gluing linoleum:

- strong connection;

- absolutely sealed seam;

- reliable and durable results.

The main advantage of gluing linoleum using the hot method is a very strong connection.

The disadvantages of the hot method include some limitations in its use. This welding option is not suitable for all types of linoleum. It is designed for joining rigid and dense fabrics. The hot method is not suitable for gluing soft linoleum. Under the influence of high temperature, the material will melt, so the joint will be damaged. The same applies to low-quality budget types of coating.

Cold welding for metal: scope of application (read more)

In addition, hot welding requires certain skills. Without knowing how to properly glue linoleum using this technology, it is very easy to make a mistake and ruin the coating.

On a note! Sometimes craftsmen use a powerful electric soldering iron instead of a torch. This option is suitable as an alternative, but it will not help to achieve a perfectly even seam.

Types and characteristics of glue

How to glue linoleum to the floor? There are two main types of adhesives on sale - dispersion and reaction. The choice depends on the characteristics of the coating and the surface on which it is laid.

Dispersion adhesives

All products of this type are aqueous emulsions of polymer resins with the addition of various fillers and mineral particles. The benefits are obvious. Facilities:

- do not have an unpleasant odor;

- elastic;

- due to the water base, they are non-toxic and environmentally friendly;

- have excellent adhesion to the base.

The products are suitable for gluing linoleum to concrete floors. After hardening, they are not susceptible to moisture and perfectly seal joints and seams. The price is low: for example, the popular Homakoll glue costs 200-250 rubles/kg. Consumption per 1 sq. m is minimal, while many adhesives are frost-resistant.

Dispersants are divided into several groups:

- acrylate with acrylic resins are suitable for fastening to wood, concrete, mineral bases of semi-commercial and commercial linoleum;

- polyvinyl acetate, bustylates with the addition of latex, chalk are suitable for gluing thick PVC coating on a felt base to fiberboard, chipboard, concrete;

- compositions such as “Gumilax” based on rubber and latex resin are suitable for homogeneous material or foamed household coating on a natural basis;

- electrically conductive adhesives with a dispersion of conductive powder are used when laying antistatic linoleum;

- rubber mastics with bitumen resin are used for flooring on the first floors, in damp rooms. The rest are only suitable for rooms with humidity up to 55-60%.

Many dispersion adhesives cannot be used at low temperatures, so for a balcony, summer kitchen or other similar premises it is better to purchase a composition marked with frost resistance. It will not crumble even when frozen. When purchasing, be sure to check the GOST instructions, check the certificates of conformity and the date of issue. Expired adhesives partially lose their properties.

Reaction compositions

How to glue the coating reliably in difficult areas? For this purpose, reaction adhesives are used, for example universal and for carpet. They are called “cold welding” and are used for soldering seams and joints.

The components of the composition react with the material. After polymerization, a hard, moisture-resistant layer is formed between the base and the floor covering, resistant to tearing and shear. The bonding strength is very high, the joint can withstand shock loads and vibration.

Adhesives come in one-component and two-component types; the latter must be mixed before use.

Scope of use of reaction adhesives:

- offices and other commercial premises;

- rooms with high traffic - living rooms, hallways, kitchens;

- bathrooms;

- balconies;

- stairs, common corridors.

All adhesives can be divided into two groups depending on their composition:

- Polyurethane. Suitable for any type of linoleum, on all known substrates. They are often used in residential areas, as the unpleasant odor is weak and disappears quickly. The cost is high - from 400-500 rubles per kilogram.

- Epoxy. Consist of epoxy resin and hardener (two-component). Their strength is even higher, but they contain toxic components (solvents). Typically, such adhesives are used for outdoor work. Price – from 600 rubles per kilogram.

Most reactive adhesives have a severely reduced adhesion rating when used on dirty floors. Therefore, you should wash it thoroughly before work. Substrates made of mineral materials need a layer of primer - this will reduce glue consumption and improve adhesion

The disadvantages of adhesives include their rapid flammability - installation must be done with great care

Cold welding of linoleum: pros and cons of technology

The instructions for using cold welding convince us that this method is much simpler than the technology of hot gluing the material. The work does not require special skills or knowledge, and there is no need to purchase special equipment. This method is suitable for renovation work in an apartment that is carried out independently.

The cold welding method is much simpler and more accessible, but requires even cutting of the joints.

For welding, a special glue is used that acts as a solvent. It softens and fuses the edges of the canvas. After the glue dries, a durable monolithic coating is formed. The seam is so thin and neat that it is difficult to notice unless you look closely.

The use of cold welding has many advantages:

- the result of gluing is quite difficult to notice with the naked eye;

- the work requires a minimum set of tools and materials - masking tape and special glue;

- the process will not take much time;

- the ability to process joints of different widths;

- the low price of cold welding for linoleum, combined with the economical consumption of glue, allows you to seal large seams with just one tube (this option is much more profitable than masking the joints with metal thresholds).

A significant disadvantage of cold welding is the limitation on the use of this technology for joining multilayer linoleum. In this case, the joint between the canvases will be too noticeable. It is also not recommended to use the cold method if a layer of insulation is laid under the linoleum. In addition, the glue contains toxic substances, so during work it is imperative to protect the respiratory tract with a mask or respirator.

Note! When purchasing glue, it is necessary to check the quality of the composition and its compliance with the requirements of the SNiP standards system.

It is not recommended to use the cold method if the linoleum is insulated.

What it is?

Linoleum is an artificial material that is produced on the basis of various chemical compounds. The joining of sheets creates a small gap, which is not aesthetically pleasing or beautiful. To obtain a solid seam, the cold welding method is used.

This approach involves the use of a special glue that connects the linoleum sheets into a single whole. When exposed to a substance, a chemical reaction occurs that makes the material liquid. During this short time, the joints have time to set and form a strong connection. Cold welding is a relatively simple joining method that can be performed even without experience and a special tool for soldering (soldering iron, etc.).

The properties of the glue are such that they allow you to work with joints of different widths. The resulting joint also has plasticity and its characteristics are practically no different from those of linoleum.

Choosing adhesive for joints of linoleum, plastic and metal

You can find many varieties of linoleum on the construction market. To make the coating, manufacturers use different types of raw materials, so not only the appearance, but also the properties of the material may differ. When thinking about what glue to use to glue linoleum to linoleum, you must take into account that these compositions are not universal.

The best choice for working with coating is adhesive made on the basis of polyvinyl chloride. Most modern types of linoleum are made from this raw material. Despite this, you can find canvases made from other materials on sale. Before purchasing glue, be sure to check the composition of the linoleum.

What did felt give to linoleum?

Felt linoleum is less deformed. A patent for the production of PVC material was seen by the world 150 years ago. Since that time, linoleum has not lost its popularity, despite the existing disadvantages:

- significant residual deformation;

- low ability to resist moisture;

- inability to absorb noise;

- poor protection from fire and combustion;

- low level of thermal insulation.

Linoleum with a felt base is almost completely devoid of all these negative aspects. Instead, he demonstrates:

- The deformation has become noticeably less, and all due to the elasticity and softness of the multilayer structure;

- The noticeable hardness of the coating has disappeared. Now it is springy, even if it lies on a concrete base;

- Felt-based linoleum demonstrates excellent sound insulation properties;

- The felt is impregnated with specific anti-flammable additives. This does not exclude the possibility of fire, but makes it minimal and not so large-scale.

If we summarize all this, we can say the following: linoleum on felt is a coating that retains heat well, is almost soundproof, durable and capable of maintaining a decent appearance over a significant period of use.

Types of glue for cold welding linoleum

There are three types of glue for joining seams between sheets of linoleum - A, C and T. They have different consistencies and degrees of impact on the material. When choosing a composition, you need to take into account the size of the gap.

Type A product is an adhesive with a liquid consistency. It contains a large amount of solvent component. This option is used to connect segments between which a small gap has formed - up to 2 mm. Thanks to its liquid consistency, this adhesive easily penetrates narrow crevices and fuses material fragments well into a solid coating. The quality result depends on how tightly and well the sheets are joined. Linoleum sheets should lie flat. The ideal result is obtained by joining factory edges.

There are three types of linoleum glue on sale - A, C and T.

Type C product has the appearance of a mastic for linoleum with a thick consistency. This adhesive is designed to seal gaps measuring 2-4mm. The mastic contains less solvent, and the main component is polyvinyl chloride. This mass is so effective that it can perfectly join sheets with uneven edges.

On a note! Using a type C product, you can repair the coating. This glue allows you to get rid of minor damage. Due to the low price of cold welding, you can save a lot and restore the coating without resorting to a complete replacement of linoleum.

Type T glue is used very rarely. It is intended for professional use when connecting sections of multi-component linoleum. This product contains polyester and polyvinyl chloride. Due to these components, the seam is elastic and at the same time very durable.

According to reviews, cold welding for linoleum of these brands is considered the best:

Homakol S 401 is used for soldering PVC boards.

- Werner Muller - type A composition, complies with international standards and is used to create durable seams at the junction of materials. Glue consumption – 44 g/25 lin. m.

- Tarkett is a universal-purpose composition that is suitable for joining cuts with uneven edges and welding multi-layer linoleum.

- Homakol S 401 – used for gluing commercial materials, as well as for soldering PVC boards.

- Rico - contains no toxic substances, which were replaced by polyurethane foam and artificial rubber. Moreover, this did not affect either the price or the quality of the glue.

In the budget category, Sintex and Secunda are recognized as the best products.

Criterias of choice

The efficiency of welding linoleum coating depends on the selection of the adhesive composition. All types of mixtures for non-thermal gluing of PVC have a transparent structure and do not disturb the color scheme in the seam area.

But it is necessary to take into account a number of conditions that determine the use of different types of adhesives.

The choice depends on the type of linoleum

Adhesive mixtures A and C are used with PVC coatings.

Class T cold soldering compound is used when connecting:

- polyester materials;

- heavy multi-layer commercial fabrics;

- linoleum on a duplicated basis.

This is a material based on felt (textile) and fiberglass.

Duplicated linoleum

Attention! Type A mixture is not suitable for soldering linoleum on a felt base.

Cover age

When working on cold soldering, it is necessary to take into account the properties of the coating:

- Compound A is used to join new linoleum;

- more viscous composition C - for repairing old coatings;

- T-class can be used to work with material of any age, but new installation is preferable.

Quality and shape of linoleum cutting

To achieve a good result in terms of strength and appearance of the seam when joining fabrics with compositions A and T, it is necessary that the joint be prepared with high quality, without cracks.

Preparation of the joint of the panels

The use of type C welding does not imply strict requirements for the quality of preparation of the panels for gluing. The predominance of polyvinyl chloride in this mixture allows:

- fill wide, up to 4 mm, seams;

- solder uneven edges of the canvas;

- join fabrics with complex cutting shapes, make appliqués.

Experience of the person who will perform the work

The simplest technology is considered to be joining linoleum sheets or repairing them using a more viscous composition of grade C.

With some skills, working with mixture “A” is not very difficult. An inexperienced repairman can also handle them.

But technical difficulties may arise with T-welding of multilayer semi-commercial and commercial coatings of a higher class. Therefore, repair specialists often work with this compound.

How to choose the right cold welding for plastic

Polyvinyl chloride and other types of polymers are widely used in modern industry, so there is a separate type of adhesive on the market for cold welding of plastics.

One-, two-component and rod products are available on sale.

This tool is used:

- for repairing plastic components of the body part of technical products;

- connection and alignment of car body parts;

- repair of fishing gear;

- soldering of units and elements made of plastic.

There are several types of glue for merging plastic using cold welding technology:

- One-component – a universal-use product, suitable for joining any types of plastic. Its consistency is the same as that of conventional adhesive used for office needs.

- Two-component - the main components of this glue are resin and filler. According to the instructions, cold welding of this type is mixed in equal proportions before direct use.

- Rod - looks like a pencil with adhesive filling inside. Before use, the product is thoroughly mixed to obtain a homogeneous mass.

When choosing a composition for work, it is imperative to take into account all the characteristics of the materials that will be glued. First of all, you should find out what temperature cold welding can withstand. Some parts are exposed to high thermal conditions, so it is important that the connection can withstand such stress. Standard glue options (depending on the brand) perform well in the temperature range from 200 to 260 °C.

When choosing cold welding, you need to take into account all the characteristics of the materials that will be glued together.

In addition, the degree of loads that the connection can withstand (tensile and shear strength), as well as the drying speed, are important.

On a note! For gluing plastic cases and thin parts, it is better to use a liquid compound. Rough types of work, such as connecting elements of sewer and heating systems, leveling a bumper or fastening storm drains, require more reliable fixation. For these purposes, it is recommended to use welding with a consistency similar to plasticine.

Which cold welding is better for aluminum: tips for choosing a composition

The composition intended for welding aluminum is sold in the form of a liquid two-component adhesive or mastic. Epoxy resin is used as a base. In addition, the composition includes additives and special fillers, which increases the strength and resistance of the connection to high temperatures and aggressive substances. These components also improve the adhesive properties of the weld. This glue will be very useful if you need to carry out repairs in difficult conditions.

Construction stores offer a huge range of products for gluing aluminum, both domestic and foreign. To avoid making a mistake with your choice, you need to:

The market offers a huge range of cold welding for aluminum.

- make sure that the characteristics of the glue meet the requirements of the types of work that will be performed with its help;

- give preference to universal options designed for gluing aluminum to other types of materials;

- carefully study the manufacturer’s recommendations along with the instructions;

- consult with the seller;

- get acquainted with consumer reviews left about cold welding.

In addition, you should take into account the fact that liquid compositions take much longer to dry than mastic.

How to use cold welding when laying linoleum

The process of soldering the coating is quite simple. Even a beginner can cope with this work, the main thing is to fully comply with the technology and act carefully. Before gluing linoleum joints, you need to make sure that all the necessary tools and equipment are at hand.

When purchasing linoleum, you need to take the material with a margin of 5-6 cm.

In addition to glue, you will need:

- Ruler and square - it is advisable to use metal models for these purposes. Products made from such material are not deformed. At the same time, they are very thin and smooth. The ruler must be long.

- Masking tape – as an alternative, if you don’t have it, you can use a double-sided version.

- Cutting tool - the knife blade must be sharp so that all cuts are as neat as possible.

- Protective backing - placed under the seam to prevent damage to the floor during the cutting process of linoleum. For these purposes, plywood, thick cardboard, chipboard or a piece of old linoleum can be used.

- Protective equipment - a mask or respirator to protect the respiratory tract, as well as gloves.

On a note! When buying linoleum, you need to take the material with a reserve, since for leveling and high-quality joining of the canvases you will need an additional 6 cm.

How to cut linoleum at home and how to do it correctly

To cut natural linoleum and polyvinyl chloride coatings, you can use several tool options.

To cut linoleum, you can use a construction knife, a linoleum knife, and a flooring cutter.

A construction knife is a tool with a retractable design with a replaceable cutting blade that is rigidly fixed. Outwardly it resembles a stationery knife, but it is adapted for construction needs. Used for cutting thin and thick materials. During operation, it is imperative to control the movement of its blade.

A linoleum knife is a tool whose cutting element is curved; in some models it has the shape of a hook. Suitable not only for cutting linoleum, but also for cutting carpets and other soft coverings. This knife is convenient for making straight and curved cuts.

The cutter for flooring material has many modifications. The option, which is adapted for linoleum, is equipped with a disk-shaped cutting element, which is fixed on a special frame with a handle. With its help you can make high-quality cuts with a smooth edge.

It is very convenient to cut linoleum with a hook-shaped knife.

The strength of the soldering of the sheets depends on how smoothly the cuts are made. Before gluing linoleum using cold welding, you need to carefully and accurately cut the material. Before starting work, the coating is kept indoors for 1-2 weeks. The exact period is indicated by the linoleum manufacturer. This is necessary so that the material adapts to the temperature conditions of the room.

In order not to make mistakes when cutting linoleum, it is advisable to take measurements several times. Based on these data, a calculation is made. By drawing up a layout of the canvases, you can make your work much easier.

Allowances when cutting material:

| Room length, m | Allowance size, mm |

| 5-6 | 20 |

| 6-10 | 40-50 |

| 10-12 | 50-70 |

Allowances compensate for the natural shrinkage of the material, as well as losses during the cutting process. Cutting linoleum should be done with confident movements, applying pressure. After this, the canvases are kept indoors for 3 to 5 days until they straighten.

Note! You should not try to remove “waves” from the surface in any way. If the material is of high quality, it will straighten itself.

A construction knife for linoleum looks like a stationery knife.

Then the canvases are laid out around the room and in places where communications or decorative elements protrude, the excess is cut off. Before doing this, you need to prepare a pattern and use it to transfer the markings onto the linoleum.

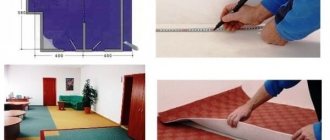

Laying linoleum: how to join sheets before soldering

Before soldering linoleum, you need to make sure that its sheets are fixed correctly and their edges are well joined. In this case, the glue can evenly fill the gap and form a strong connection.

Before gluing, the base is cleared of debris and dust. If linoleum with a pattern is laid in the room, one sheet should be laid out on the floor, and the second should be placed on top of it with an overlap of approximately 5 cm. A protective backing should first be placed under the material. It must be present along the entire length of the joint. The position of the segments in relation to each other changes until the pattern in the joint area coincides.

Then markings are applied to the top sheet indicating the joint location. It is desirable that this line passes through the center of the overlap. Now you can start removing excess material. To do this, you need a long ruler, which needs to be placed along the future seam. Be sure to make sure that both canvases are underneath. Using a ruler, the canvas is pressed well, and a cut is made along it. To make the joint for welding linoleum smooth and neat, you need to cut two sheets at the same time.

Fixing the material can be done in different ways. To achieve a reliable result, you need to cover the entire floor surface with glue. The second method involves fixing the material using double-sided adhesive tape. In this case, the canvases are not attached so rigidly. Most often, this method is used if linoleum will be used as a temporary covering. The adhesive for fixing the canvas to the floor is prepared according to the manufacturer's instructions, which is included with the package. It is better to use a spatula to apply the composition.

To properly join the sheets before soldering, you need to use adhesive tape.

There is a certain procedure for installing the coating. First, the material is attached to the wall. Next, the glue is applied to 60-70% of the linoleum using wave-like movements. The amount of composition must be controlled so that there is no excess. Then the canvas must be carefully lowered and smoothed over the entire area. To do this, its surface is rolled with a heavy roller. The covering is installed in the same way on the second half of the room.

On a note! If a tool such as a heavy roller is not at hand, you can use a building level instead. It should first be wrapped in soft cloth.

Glue consumption for welding linoleum seams and methods of its application

Before gluing the seams of linoleum, you need to evaluate the quality of its cutting and the shape of the edge. If the joints are uneven, it is advisable to use a product with a high content of polyvinyl chloride. Such sections usually diverge easily, and with the help of a thick composition, all voids can be efficiently filled and the material can be prevented from shifting. Glue with a large amount of PVC is ideal for joining fabrics with complex angular shapes.

If cold welding will be used to glue old linoleum that has been in use for a long time, it is better to use a composition with a viscous consistency. Such products contain a small amount of solvent, but they provide a high quality connection. For gluing a new coating, compositions with a liquid consistency are suitable. After them, the seam turns out to be very neat and almost invisible, but the reliability of the connection is much lower.

To glue old linoleum, it is better to use a compound with a viscous consistency.

There are two ways to apply glue for welding linoleum:

- Using a tube and a needle, carefully lubricate both cuts. Under the influence of glue, the edges are fused and firmly connected to each other.

- First, only one edge is coated and applied to the floor. Then the second cut is processed using glue and placed tightly next to it. After this, the seam needs to be smoothed out.

The consumption of the composition depends on the qualifications of the person who does the gluing, the thickness of the linoleum, as well as the characteristics of the product itself. In most cases, type A solution is used. On average, a tube with a volume of 50-60 mm can cover 25 linear meters. m seam. Grade C glue is more viscous, so its consumption is greater. For processing 25 linear m of seam will require at least 70-90 ml. Some manufacturers indicate the volume of glue in grams. This nuance must be taken into account when calculating the required quantity.

The glue consumption of popular brands is shown in the table:

| Name of glue | Capacity volume | Covered seam length, linear m |

| Axton | 60 g | 5 |

| WernerMuller | 44 g | 25 |

| Homakol S 401 | 60 ml | 25 |

| Rico | 60 ml | 25 |

| Second | 75 ml | 50 |

| Tytan | 100 ml | 45 |

| Sintex | 100 ml | 50 |

How to use cold welding for linoleum

When the cuts and joints of the material are adjusted, you need to make sure that there are no bubbles left under the surface of the canvases. During the welding process, air can move into the joint area and eventually destroy the seam. The canvas should be pressed down with a small press. Before starting work, it won’t hurt to study the manufacturer’s instructions, which indicate how to properly glue linoleum and at what temperature it is recommended to use glue.

On a note! Many adhesives contain aggressive components that can damage linoleum. This is especially true for coatings with a glossy sheen. To prevent the composition from getting onto the front surface, the material along the entire length of the joint is glued with masking tape. This must be done so that only a few millimeters of the edge part remain for the glue to interact. Scotch tape is applied to both edges.

Using a special knife, you need to cut a groove between the sheets. In this case, you need to act very carefully so as not to damage the material on the sides.

The groove between the sheets is filled with glue until it appears above the surface of the tape.

Included with the welding glue is a special needle-shaped attachment. It needs to be put on the tube, after which you can start working. The groove between the sheets should be filled with glue until the composition appears above the surface of the adhesive tape by about 3-4 mm. Then the needle must be moved sequentially along the entire length of the joint, applying the product in the same way. After filling the seams, the glue must be left to dry for 15 minutes. During this time, the composition will set a little, after which it will be possible to remove the tape from the surface. It takes about 3 hours for the glue to dry completely.

It is not recommended to use a hair dryer or other methods to speed up drying. Under the influence of temperature, the composition can sharply decrease in volume, which as a result will negatively affect the quality of the resulting compound. After the cold weld has completely dried, you can remove the excess adhesive. It's better to do this in two passes. First, strongly protruding areas are cut off, and after a day you can remove the remains and carefully clean the surface. It also doesn't hurt to go over the seam with felt.

If the composition does get on the surface, do not wipe it off immediately so as not to deform the seam and damage the coating. It is better to wait until the glue is completely dry and then cut it off using a sharp utility knife.

How to lay linoleum on a concrete floor: (read more)

In general, anyone can master the technology of cold welding linoleum. This process is quite simple and does not require much experience. The main thing is to follow safety precautions and act very carefully.

Instructions for use

How to cold weld a linoleum joint? To carry out all the work correctly, you must strictly follow the instructions. It is described step by step below.

Seam formation

After purchasing the coating, its approximate fit, you need to form the optimal seam. To do this, lay both pieces as they will lie on the floor. In this case, the overlap should be 5 cm. Next, you will need a strong metal ruler and a pencil. Fasten both edges of the coating together with double-sided tape so that they do not move during cutting. Then markings are applied strictly in the middle, pressing the coating tightly with a ruler. Then they cut along the markings with a sharp knife to get even edges.

Cleaning the base and seam

Before gluing, you need to thoroughly clean the floor from dirt, remove the rest of the old coating, and vacuum it. Before work, all parts must be dried. Also, as preparation, you should protect the edges of the linoleum from damage. Cold welding contains aggressive components that can corrode the material. Glossy linoleum suffers especially badly. To avoid such troubles, you need to buy wide masking tape and cover the edges of both canvases with it, leaving a few millimeters for glue.

Cold welding application

Before work, you need to prepare a clean cloth or cotton swabs to remove excess and smudges of glue. There are two ways to apply the product:

- First. Using the tube nozzle, squeeze the glue onto both edges at once. At the junction, the linoleum will become liquid and the edges will melt.

- Second. Lubricate only one edge and place it on the floor. Then apply glue to the second edge and place it tightly next to the first. Level, smooth out the seam.

After a few hours you can walk on the floor without fear; the exact drying time is indicated in the instructions for the glue. When the linoleum is dry, you need to remove the masking tape.

https://youtube.com/watch?v=A5XFE6hCQX8

Removing excess glue

Often, excess composition flows out. You should not touch them while welding the edges; this can cause the floor covering to peel off and the seam to break. Dried cold welding is removed in 2 steps. Since a fresh seam is elastic, strong tension and cutting may leave a crater. It is better to first cut off the excess that sticks out on the surface, and after a day to finish the job. You can do all the work yourself, without the help of specialists. Installing a weld is a painstaking task, but quite doable!