Over time, linoleum has been and remains the most practical material used for finishing flooring. If you lay it well on the base and attach it firmly, it will serve you for at least ten years. To secure linoleum to the floor, you can use a number of techniques, the most reliable of which is gluing it to the base. But it's not that simple. To answer yourself how to glue linoleum to concrete, first you need to know what load is expected on it. Let me now tell you how to glue it, how to do it correctly and which adhesives will best cope with this task.

If you have not yet decided on the choice of suitable linoleum for your home, then we recommend that you read the article where we told you how to choose linoleum for your home.

Is it worth gluing?

Not glued linoleum

Starting this article I want to ask you a question - think about it - is it worth gluing linoleum at all? Most likely worth it! But not in all cases. If your renovation involves laying linoleum in one large sheet, then you can simply smooth it out with a roller and secure it around the perimeter with a plinth. If, nevertheless, the idea of gluing has overtaken you, then in order to decide which glue to choose, let’s clarify some of the nuances on which the answer to this question directly depends.

First of all, you need to consider the conditions under which the floor covering will be used. You need to build on the traffic flow of the room. For example, if linoleum is laid in the bedroom, then fixing it with glue to the base is pointless. If, however, for peace of mind you still want to put it on glue, then it is not necessary to smear the entire floor; it will be enough to apply glue in dots along the edges and a cross, crosswise in the center. It is recommended to use an adhesive with moderate adhesive ability as an adhesive base.

It should be!

But if you are going to lay it, for example, in a corridor where there is high traffic or in commercial premises where you plan to frequently move heavy loads or other difficult operating conditions, then you cannot do without glue. If a high load is expected on the finished coating, then it will be necessary to completely cover the entire surface of the concrete screed with glue so that it does not move and waves do not form. In addition to cross-country ability, the quality of the coating plays a special role. If it is elastic and fits well on the floor, then you can simply secure it with baseboards and leave it like that. He's not going anywhere.

Subtleties of the process

Any type of floor can be called a concrete base if a cement mixture was used in its production. Linoleum is laid both on any types of screeds and on floor slabs. It all depends on the purpose of the room and the load on the floor.

Base options are represented by different percentages of sand, gravel and crushed stone. Whatever the proportion of a particular filler in the screed, the floor is considered an absorbent subfloor . This means that the surface absorbs and retains gaseous, liquid and solid substances that are in its vicinity well.

Adsorption, which is characteristic of concrete coatings, is a good quality, especially if linoleum is laid for a long time.

But few people would like to see the same interior all their lives. Additionally, even the best brands of flooring are prone to wear and tear.

The correct installation technology is characterized by the use of compositions that allow you to easily change the material to another in the future. In this case, the adhesive mass should fix the linoleum well during use. When choosing an adhesive, it is recommended to choose the one recommended by the product manufacturer.

The following types of linoleum are suitable for a rough field:

- With insulating base. The reverse side of this material is covered with a substrate that does not allow heat and sound to pass through.

- Alkyd or glyphthalic. They are made on the basis of fabric or other fabric.

How to glue

There are three ways to glue linoleum to concrete, the simplest of which is gluing it with double-sided tape. You can do this type of gluing yourself. The second way is to use special glue and mastics. Although this process is more difficult, the reliability is much better.

The third type is the least reliable. No gluing. With this installation, after some time, waves and folds may form on the floor. Allowed for use only in low-traffic areas. Now let's find out what glue to use to glue linoleum to concrete or is it better to use mastic?

Important! Any type of glue or mastic must be applied with a notched trowel. Then, linoleum blanks are spread on the plastered floor and rolled evenly with a roller or smoothed with a brush. The manufacturer indicates information on glue curing on the packaging.

What to do if linoleum starts to peel off

It often happens that the fixed coating peels off from the floor after some time and requires repair. How to fix the defect? If swelling occurs, you can make a puncture in the fabric using a thin awl. The air is then released and the area is ironed with a hot iron through a thin sheet of white paper. The glue melts and re-bonds the surfaces.

Gluing joints together

How to glue linoleum together if the fabric comes apart at the joints? The separation of the seam indicates a violation of the cold welding technology. The resulting defect can be easily eliminated - the seam is cleaned and degreased with alcohol and gasoline. Then the coating is carefully folded back and an adhesive is applied underneath it. Next, the joints are fastened by cold welding.

What to glue

As an adhesive base, you can choose a composition that is suitable specifically for your needs. Let's look at all their types in more detail.

Mastics

Using mastic when laying linoleum on a concrete floor means saving on waterproofing. Due to their strength and resistance to moisture, adhesive mastics cope with this responsibility best.

The main thing is to apply the mastic evenly

Dispersion adhesives or bituminous synthetic mastics are best suited for jute-based linoleum. When applying such a composition, it is necessary to maintain its thickness no more than 0.5 mm. If you have the task of gluing linoleum with a heat-insulating base, dispersion glue will come in handy. It is recommended to apply it in a layer of just over 7mm. Mastics based on synthetic resin or rubber will best hold linoleum without a base. The layer of this composition applied to the base should not exceed 4mm. Another type of glue for linoleum is a composition prepared by yourself at home. There are a lot of recipes on the Internet for preparing it.

applying bitumen mastic to the base

Bitumen mastic

It is also one of the most suitable compositions for gluing elastic floor coverings to a concrete base. This type of glue is simply irreplaceable if there are any defects on the screed. It is also perfect for waterproofing. It is worth considering that before using bitumen mastic as an adhesive composition for linoleum, the concrete screed must first be primed with a special impregnation to increase adhesion.

How to make glue for linoleum on a concrete floor yourself?

To begin, take scraps of linoleum and chop it with a utility knife or linoleum cutting knife. Place the resulting sawdust in an iron or plastic container, fill it with a mild solvent that will dissolve the material. Stir the resulting mixture for some time until the linoleum sawdust is completely dissolved. And now, the glue is ready!

If you decide to make glue yourself, think twice! Is it worth saving on this when the market offers a lot of glue options, distinguishable both by type of application and price.

Special glue

High-quality linoleum glue dries quite elastic. Thanks to this ability, its peeling under any types of loads is completely eliminated, which does not allow it to peel off under any types of loads. According to the method of gluing linoleum, compositions are divided into two types: for fixation and continuous gluing.

There are different types of compositions applied in a continuous layer to the base:

- One-component;

- Two-component;

- Polyurethane;

- Solvents;

- Water-dispersed.

Variety of adhesive choices for linoleum

Water-dispersed adhesive mixtures are very popular among them. Their popularity is caused not only by environmental safety, but also by the fact that they more reliably fix the coating to the concrete base and have a high elasticity class. If you prefer to save on adhesive base, we recommend that you use glue for fixation. This composition has permanent tack and moderate adhesiveness. It is a pleasure to apply it, as it does not dry out and there is no need to rush to glue the material. The consumption of such a composition is as minimal as its price.

Step-by-step instruction

After preparing the linoleum and rough concrete floor for installation, you need to study the operating technology. There are two methods of fixing the material to the surface. The choice of approach for gluing linoleum to a concrete floor depends on the type of coating.

Bonding household coverings

Linoleum of this category is usually used in a single sheet. The width of the material can reach up to 5 meters.

This allows you to not have to worry about adjusting seams and precise cutting at home. It may be necessary to trim the canvas only along its perimeter. There is no need to worry about the perfect evenness of the edges - the plinth will hide all the flaws.

Household material is not as brittle and tough as commercial material. Unfolding and laying out does not require precision or high attention.

The disadvantage of this type of linoleum is its fragility, in addition, it requires some time before laying for leveling. Curls will go away faster once unrolled than commercial brands.

At the same time, it is impossible to fix the material until it is completely straightened. If the canvas is much larger than the area of the room, you need to trim it. It is important to leave 5 cm at the edges.

Preparation of the material before attaching linoleum to concrete:

- Rolling out and laying the fabric. The edges should extend onto the walls by a maximum of 5 cm.

- Expelling air from under the coating using a brush in the direction from the center to the edges. Instead, you can use your feet in felt boots.

- Rest and smooth the fabric.

- After the irregularities disappear, the linoleum is cut. To do this, press the material against the wall with a ruler and use a knife. Between the wall and the coating you need to leave about 5 mm, but not more than 10.

- Cutting external and internal corners. In areas of pipes and openings, reserve material should be left. After fixing, you can remove the excess.

- Rest the linoleum for several days. During this time, the material should take a permanent shape. He may stretch or shrink a little.

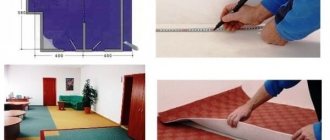

Glue installation technology

We figured out what glue to use to glue linoleum to concrete, now let's briefly look at the gluing process itself. I would like to immediately draw your attention to the fact that it is advisable to apply glue not only to the floor, but also to the linoleum itself. The first step is to cut the original roll of material and adjust it to the size of the room. It is recommended to do this after the linoleum has been in the room for some time and has settled to a given area. If the floor area is blocked by various obstacles (pipes, niches for batteries, etc.), it is recommended to immediately cut and fit everything.

Important! It is not recommended to cut off large pieces initially. It is better to initially cut off several short pieces, because in the future, if a cut becomes necessary, there will be another seam, and at its joining you will again lose a certain amount of material.

Do the same with the other half.

Next, fold back half of the spread material and coat the floor with glue, using a roller or spatula. Lay the folded edge and smooth it carefully with a brush or something suitable. A similar operation must be performed on the other edge. It is especially recommended to apply glue to the joints and on the threshold at the entrance to the room. At the joints, the material should be bent a little and a little more glue or mastic should be applied with passion.

Specifics of gluing linoleum to concrete

To get an even result without flaws, as well as a durable one, it is necessary to carry out gluing in stages. The work steps include the following:

- A piece of linoleum is cut to fit the size of the room, a cut is made taking into account an overlap of 5 centimeters on the walls on each side. Before cutting, the linoleum is spread on the floor and leveled so that there is no air left under it, wait ten days so that the material fits well, only then you can cut the edges;

- Again, they wait a couple of days for the installation process to complete;

- If two pieces are used, then they are glued together with adhesive tape, after which cold welding will be used;

- Half of the piece of material is folded back. to apply an adhesive solution to the concrete;

- Return the canvas to its place and carefully level it with a brush, knocking out the air from under it; also work with the other half.

A piece of linoleum is cut to fit the size of the room, a cut is made taking into account an overlap of 5 centimeters on the walls on each side.

Difficult places and coating care

When the gluing process is completed, the dirt remaining after the repair is removed using the dry method. Wet washing is not allowed for the next 10 days. You can coat the surface of the material with a special emulsion that protects against dirt and dust. You can wash linoleum with soapy water.

You can wash linoleum with soapy water.

Tape laying technology

glue linoleum with tape

The glue itself is essentially a less durable, but economical material for gluing and joining linoleum. If applied incorrectly, it is much easier to dismantle than mastic or glue. To lay linoleum on double-sided tape, stick the tape on the concrete base, so that one part covers one sheet, and the second covers the other, without removing the protective strip from it, from the side of the linoleum, it would not be superfluous to apply it pointwise along the entire perimeter of the canvas small stripes. Then spread the covering and lift it, or better yet, roll the joint in the opposite direction. Remove the protective layer from the tape and spread the linoleum over it. It is worth remembering that the durability of this method will depend not on how long you hold the linoleum against the tape, but on how much you smooth it out from the first run. After this, repeat the operation with the second piece of cut linoleum.

Important! It is best when the coating and glue are purchased together, then the seller can offer the best option for the job.

Commercial linoleum: installation features

Commercial roll materials are used in public spaces with increased traffic and increased mechanical loads.

Russian-made glue. Maintains fixation to the concrete base at a temperature of -25 degrees

Laying commercial linoleum is similar to working with household or semi-commercial material, but there are some technological nuances:

- When preparing the base, more stringent requirements are imposed on the quality of surface treatment; the primer is applied 2-3 times.

- The temperature in the room during installation is maintained within 15 - 20 degrees, humidity 40 - 50%.

- The joints are made by hot welding with a wire harness.

- Some projects provide for installation without a plinth, with the edges of the panels folded onto the walls.

- Commercial linoleum is not subject to temperature deformation; it is allowed not to leave a gap between the edge of the canvas and the wall.

This type of floor can be used in residential areas, but the cost will be higher than the usual one.

Conclusion

Roller for rolling linoleum

When you choose how to glue linoleum to a concrete floor, it is worth considering how long this coating will lie on your floor. If the linoleum is to be laid for a year or less, in the case of a rented home or office, then the mounting double-sided tape will suffice. Since if you want to take it with you, the dismantling of the coating will take place without noise and dust. But if the flooring is expensive and you want to install it in your favorite apartment, then it is better to use natural-based glue. If the screed is made with some errors, bitumen mastic is ideal as an adhesive.

Useful video on laying linoleum on a concrete floor

Viewed times: 1,023

Great article 0

Author's rating

Author of the article

Oleg Grishin

Flooring specialist with 10 years of experience. Oleg has something to share with our readers

Articles written

105

- Even more interesting:

- How to choose the best linoleum for an apartment?

- Features of caring for linoleum

- Which glue for linoleum should I choose?