Connection methods

In general, they usually try to choose the width of linoleum so that there is only one piece in the room. Then there is no seam and no problems. But there is no way to get rid of the connection of two pieces in the doors. If the class of linoleum allows it (semi-commercial, commercial), you can call specialists, they will solder the coating. They have special equipment for this. If calling specialists is not part of your plans, you can create the joints yourself. There are two options: glue or cover with a metal or plastic threshold. The choice of docking method is determined by several factors. The first is the characteristics of linoleum itself:

- connecting soft (household) materials is easier and more reliable using a threshold;

- hard (semi-commercial) is more effective to glue.

The most important thing when choosing a joining strip or threshold is to choose the right color.

So what and how to join the linoleum together depends on your linoleum. This has been verified. If you try to glue household soft linoleum, the seam will break after a short time. But you can put a threshold on semi-commerce. It will lie fine. It's just that not everyone likes this option. It is usually considered if there are no other options.

Thresholds are also laid at the junction with other types of coating. With tiles, laminate. Joining strips or thresholds also look better and more logical when connecting pieces of linoleum that are very different in pattern and color. If your class allows, you can, of course, cook it. But it will hardly look any better than with a well-chosen threshold or connecting strip.

Glue selection

It is necessary to select a product not only depending on the type of coating. The type of base must be taken into account. Some adhesives are universal, while others cannot be used to glue decking to wood (plywood, boards). If you want to save money when connecting flooring to a wooden floor, you can buy PVA.

With concrete screed it is more difficult - you will have to purchase a professional composition. When you come across a popular brand on the counter, you need to carefully read the instructions. It always indicates what the glue is suitable for. Next, a calculator will be useful to calculate the consumption of materials and, accordingly, the cost of repairs and choose a product that suits your pocket.

How to glue two pieces of linoleum

Almost any hardware store has glue for gluing pieces of linoleum. It comes in two types, which work differently.

- Type A is suitable for welding laid linoleum. It is more liquid and dissolves the edges, as if fusing two fragments. It is also called cold welding. This is a chemically active substance that dissolves linoleum. That’s why it’s called “welding”, since it works in a similar way. The seam is thin but durable. You must work with cold welding carefully. It is applied from a tube with a long spout exactly at the joint. If it gets on the surface, it will dissolve it. There will be ugly swellings, ulcers, and pits.

You can fasten linoleum together with glue - Type C linoleum seam adhesive is designed for gluing loose seams. It's thicker. Fills the gap between two pieces, connecting them very, very securely.

So the choice of the type of glue depends on whether you need to connect “freshly laid” linoleum or restore a broken seam in an already used one.

What else can be used? If PVC linoleum does not have a base, you can glue it with PVC glue. For example, “Liquid patch”, there is “Moment” and Kleyberg (Kleyberg), Sintacoll (Sintacol). These compounds are intended for gluing PVC products. If your linoleum does not have a backing, you can try. The composition also partially dissolves the parts to be glued, is applied to a degreased surface and left for a day. But it gains full strength in 7-12 days. Some compositions are tinted (Latka), there is a colorless pigment.

Cold welding is only one of the possible adhesive options for linoleum joints

For linoleum based (felt or some other) two-component glue is used: Texacol (Texacol), Bostik Vinycol 1520 (Bostik Vinykol). These compounds are mixed in certain proportions before use, then applied to the surfaces that need to be glued. They are kept for several minutes and pressed tightly. Leave for a certain number of hours. You can even glue the joints of thin sheets of linoleum. After gaining strength, they cannot be torn apart. But the exact dosage and sequence of actions must be read in the instructions for each glue, because there are differences. Failure to follow the recommendations leads to poor quality seams.

Installation procedure

To apply glue and ensure reliable fixation of linoleum, you should do the following:

- It is recommended to mix the glue in the container well. If a film appears on top, it should be carefully removed.

- Apply glue to the contact surface and level it with a spatula. There should be no untreated areas left on the surface.

- Carefully return the wrapped part to its place. It is recommended to straighten the edges.

- After rolling out, start smoothing. It is recommended to avoid the formation of air bubbles.

- Finally, tap the seams. This must be done as carefully as possible.

How to use cold welding for linoleum

How to work with cold welding is written on each tube. Please read before starting work. Please allow 10 minutes as there may be some peculiarities. Typically the sequence of actions is as follows:

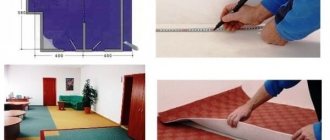

- Two pieces are laid with an overlap of 5 cm (one overlaps the other by 5 cm). Then take a ruler or rule and a sharp (very sharp) construction knife. The ruler is applied in the place where the seam will be made. In the doorway, they try to get under the door leaf or threshold, if there is one. Along the ruler, you need to cut both pieces at once. The trick is to cut through both pieces of linoleum in one pass. Therefore, you need a very sharp knife. You also need to put in a solid effort.

Linoleum joints between rooms: making the seam precise - Remove excess strips of coating. The joint turns out perfect. If the coating is monochromatic or the pattern is unclear, the connection is hardly noticeable even without welding.

- Take wide masking tape. We glue it onto the seam so that the middle of the tape is at the joint. Use your finger to press the seam and cut the tape along the seam. As a result, several centimeters of linoleum are closed on the sides of the joint. This is enough to get the job done.

- Take a tube of cold welding glue and put on a nozzle with a narrow spout. Carefully fill the seam with the compound. Remember, it is quite liquid. But if it spreads a little, it’s not scary. For protection we put tape on it. You can level the composition using a metal (stainless) plate. Plastic may dissolve.

How to glue linoleum together: if it has no base, cold welding glue works well - We wait 15-20 minutes (exactly indicated on the package), then you can remove the tape. Excess glue is removed along with it. The seam is ready.

If you have never tried working with cold welding, before gluing linoleum together indoors, practice on unnecessary pieces. Moreover, the linoleum should be the one you will weld. Each has its own nuances. After training, application “in real conditions” will go like clockwork.

Repair of a broken joint

First, a few words about why linoleum seams come apart. Most often the reason is a violation of the installation technology. What are these mistakes? What rules are being broken? Yes, basic ones. First. Linoleum should not rest against the walls. It is cut around the perimeter so that there is a gap of about 1 cm to the walls. Second. Skirting boards must be nailed to the walls, and only pressed against the floor and floor covering. Then seasonal fluctuations in size will occur unnoticed and without damage to the seams. And if a seam on your linoleum has come apart, remove the baseboards, check the gap and attach them to the walls. Then repairing the seam will no longer be necessary.

Gluing joints of old linoleum - for repairs you need type C cold welding glue

Next, we’ll talk about how to glue linoleum together if it comes apart. First, we thoroughly clean everything with a vacuum cleaner. And what got under the linoleum on the sides of the seam too. Next, degrease with any available means. Both linoleum and the floor under the edge of the covering.

We stick masking tape onto the linoleum on both sides of the joint (it comes off normally later, without leaving marks and is quite dense and resistant to chemicals). We cut along the edge with a knife. If the edges are frayed or curled, cut them off too. But don't overdo it. Cold welding type C looks normal with a seam width of no more than 3-3.5 mm. Next, it’s worth using a docking strip or threshold. Or glue a strip of linoleum, widening the seam.

Remove debris and degrease - first steps

Next, fill the free space with glue. Level its surface and leave to dry. The excess flows onto the coating, but it is covered with tape, so it's not a big deal. If there is too much glue, remove it from the tape with a piece of rag, but do not blot the seam with the rag. The surface will be uneven and dirt will accumulate in the uneven areas.

After complete drying (the period is indicated on the packaging), the tape can be removed. Some manufacturers recommend several hours of “rest” even after drying. If you need to move around the room, you can stick the same masking tape onto the dried seam glue. It will protect the surface from litter and dust.

Disadvantages and advantages of using an adhesive base

As noted earlier, many professionals are skeptical about the use of glue. Therefore, the problem should be approached with great care. Through the use of such material, the following can be achieved.

- Increase the service life of the coating. The presented position is especially relevant for thin finishing materials that are prone to mechanical coatings. The problem with thin linoleum is associated with the possibility of bending, which leaves microcracks. Over time, the latter develop into through-and-through damage. By using glue, the service life can be increased by 20%.

- Improves aesthetic properties. The use of consumables eliminates problems with bloating, the appearance of waves, and so on. Also, no cracks appear during cleaning, no displacement occurs.

Using glue to fix linoleum to a wooden floor allows you to avoid such troubles as the appearance of waves, swelling, etc. - Increases the tightness of the coating. The entire floor becomes a single whole, as it is poured together with special compounds. In the event of an emergency with communications, the risk of water or other liquid penetrating to a lower floor is reduced. If the installation is carried out on wood, then the glue protects it from damage, rotting, fungus and mold.

The more accurately the installation technology is followed, the longer it will last. It is important to note that the quality and operating time are largely determined by the quality of the adhesive composition. Please note that despite all the advantages, there are also disadvantages.

- The cost of installation increases significantly. In some cases, the use of glue is correlated with the use of other expensive materials.

- Installation time increases. Since several technological operations are added at once, the time required to complete the task increases. Labor productivity decreases, time increases, and costs increase. Typically, the masonry procedure using an adhesive base increases the time required to complete the task by 2-3 days.

It is important to consider that if you use glue, it will take a longer period of time to install the floor covering - Difficulty in carrying out repair work. If problems arise with the flooring, there will be more problems in eliminating these problematic issues. It is almost impossible to tear off linoleum; a lot of effort is required. Also, the material will receive serious mechanical damage, which will not allow it to be used in the future.

- Low environmental friendliness. Some researchers note the presence of negative effects on human health. It all depends on the chemical composition of the glue, so you can’t save money.

Using low-quality glue can harm your health

Interesting! It is up to each person to decide whether to use the technology in question or not. Be sure to weigh the pros and cons so that you don’t regret anything.

Adhesive for linoleum

How to glue linoleum together with double-sided tape

If the base is flat, the linoleum is rigid, and a large shear load (in the form of large dogs or playing children) is not expected, the linoleum joint can be fixed using double-sided tape.

Quick gluing of linoleum joints with double-sided tape

As you understand, everything here is elementary. We cut the connection to fit the ruler (described above), and glue wide double-sided tape to the base. Remove the protective film and fix the edges of two sheets of linoleum. If the pruning is done well, then there will be no problems. Unless a roll that has not rested is laid down and it may decrease in size. That's when the edges can come off the tape. But in this case, the glue seam will not hold up.

Thresholds, joining strips

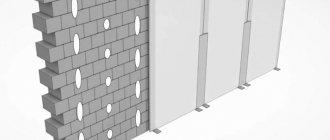

As has already been said, if linoleum sheets of different thickness, texture, or pattern are joined together, it is better not to glue/weld them, but to join them using a threshold or a joining strip. They are of two types: with fasteners installed through or with countersunk screws/dowels.

Thresholds are available for hidden or open installation

There are usually no difficulties during installation. You cut a piece of the required length (by the way, it is sold in whole strips, not by the meter; but there are ones cut to fit standard doors), apply it to the installation site and mark the holes for fasteners. If the base is concrete, we drill holes for installing dowels; if it is wooden, we pre-drill holes for self-tapping screws (in both cases we take the drill diameter a little smaller). Then we put the threshold or bar in place and screw it on.

Fasteners are usually included in the kit. So it doesn't protrude above the surface. If you buy screws/dowels separately, then be sure to have a flat head. And before starting installation, it is better to first check whether the fasteners protrude above the level of the bar. If it sticks out slightly, widen the hole (with a larger diameter drill).

Hidden fasteners are not that difficult to install

Installing a concealed threshold is not much more difficult. After 20-30 cm we drill a hole in the gap between the linoleum sheets. We install plugs for dowels in them. We thread the fastener into the corresponding guides on the back side of the decorative strip, turn it on its side, and position it so that it fits into the dowels. This is the most difficult stage - you need to hit it as accurately as possible.

When all the screws are in place, we apply force. You need a hammer and a piece of board. Place the piece of wood over the screw and hit the board with a hammer. It is necessary to hammer evenly along the entire length, and not individually. So they tapped a little, moved it, and again, and again.