Facade finishing is one of the most important construction operations. The coating of external walls is exposed to precipitation, cyclic freezing/freezing and exposure to harsh ultraviolet rays. Such difficult operating conditions place increased demands on the quality of finishing. Eliminating defects on façade walls is very expensive and time consuming. You will have to install scaffolding, wait for good weather, and remove construction debris. To eliminate the occurrence of unpleasant situations, you need to take all measures to prevent them.

Facade reinforcing mesh

Why do you need a reinforcing façade mesh?

Finishing of facade walls is carried out using various materials and technologies. Reinforcing stack is used in two cases.

To improve the performance characteristics of the plaster layer. For such purposes, it is better to use a metal mesh made of galvanized wire.

Galvanized welded mesh

Reinforcement is recommended to be used on façade walls made of foam concrete blocks; no additional measures are required for brick walls.

All metal mesh

The fact is that among the many advantages of foam blocks, you must definitely pay attention to one very significant drawback - low physical strength. Another problem is that concrete blocks begin to crumble when they freeze/thaw under conditions of high specific humidity. As a result, the cement plaster begins to peel off with all the negative consequences.

Foam block plaster

The reinforcing mesh allows the plaster to adhere to the wall surface. Conversations that such a mesh should be used when the plaster is thick, and that this prevents cracks from appearing on the plaster, are only partially confirmed. Firstly, there are simpler and cheaper methods to prevent cracks from appearing in thick plaster. The simplest one is to spread the solution in a thin layer in several stages. Secondly, the adhesion of the mortar to the façade wall can be increased by slightly increasing the amount of cement in the mortar. If this is not enough, then spray it with cement laitance.

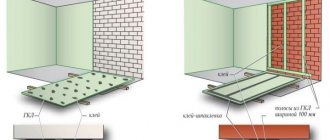

To protect façade wall insulation from damage. Reinforcing facade mesh is used during the finishing of foam insulation boards.

Plastering on foam plastic

Not to improve the fixation of glue to the surface of polystyrene foam and to prevent cracks, as some “sofa” builders write, but precisely for mechanical protection.

Reinforcement

Why do we say this? The surface of expanded polystyrene is protected from the negative effects of ultraviolet rays and, oddly enough, damage from birds. For some unknown reason, birds are very fond of pecking at polystyrene foam; if you leave it unprotected, many large and small depressions will soon appear on the surface. Conclusion - polystyrene foam needs to be covered. The cheapest and most reliable method is to use glue.

By the way, the advertising characteristics of manufacturers of plastic reinforcing mesh “they are not afraid of UV” do not in any way affect their actual performance indicators. The fact is that even the thinnest layer of glue or other cement-sand mixture does not completely transmit ultraviolet rays. Why should the consumer pay for features that he does not need? And one more nuance. Most often, builders fix the reinforcing mesh on the entire wall. We think that this is done either out of ignorance of the physical properties, or by the desire to earn more money. We recommend using reinforcing mesh to a height of 1.5–2.0 meters; there is no need to go higher. No one will damage the finish screed on the foam that high. Mechanical damage occurs due to various impacts, careless maintenance work near the facade wall, etc.

Reinforcement of structures

Mesh reinforced concrete

In individual construction, such concrete reinforcement is most often performed when constructing a monolithic floor with your own hands. In this case, the mesh for reinforcing the concrete screed can be used either factory-made, of the types listed above, or made independently by tying reinforcing bars with steel binding wire (see video in this article).

Work order:

- Clear the room of debris.

- If the mesh is in a roll, then cut into pieces of the size required for reinforcement.

- If the mesh was supplied with factory-made cards (metal or plastic composite), then lay out the sections and tie the joints with wire or plastic clamps.

Plastic frame

- In the case of making nets by hand, you need to acquire a hook and knitting wire; cut the reinforcement and knit frames of the required size from it. Further see point 3.

- For better contact of concrete with the reinforcement frame, we do not place the frame on the base, but install it on special “chairs” (see photo).

Frame on "chairs"

- After completing all the work described above, we proceed to preparing and laying the concrete mixture.

Mesh for reinforcing concrete screeds is produced in a wide range by specialized reinforcement and welding plants or, in the case of plastic composites, supplied to the retail chain by specialized enterprises. The selection of the necessary reinforcement must be made taking into account the type of monolithic structure and the required performance characteristics of the coating.

Types of façade reinforcing mesh

Facade mesh

Facade reinforcing mesh is made of galvanized wire or polymers. The former are used for facade plaster, and the latter are used for universal use.

| Name | Cell sizes, mm | Roll dimensions, m | a brief description of | Approximate cost, rubles |

| Safety | 2×2 | 1×50 | The material of manufacture is fiberglass, used to reinforce plaster near door and window openings, to level the joints of insulation boards | 900 |

| OXISS | 5×5 | 1×50 | The mesh has enhanced protection against alkalis and can withstand significant dynamic and static forces over a long period of action. | 1050 |

| Fiberglass mesh facade | 5×5 | 1×50 | For holding plaster on concrete facades and insulation boards. Withstands a tensile load of at least 1400 N/cm. | 1400 |

| STREN S5 | 22×35 | 2×25 2×50 | Withstands rough and finishing facade plaster up to 5 cm thick. | 2750 5500 |

| KREPIKS Facade 1300 | 4×4 | 1×50 | Fiberglass, protected from alkalis and ultraviolet radiation. | 1560 |

| KREPIKS Facade 1500 | 5×5 | 1×50 | Reduces the likelihood of cracks due to thermal linear expansion | 1970 |

| KREPIKS Facade 2000 | 4×4 | 1×50 | For reinforcing finishing plasters during finishing of the insulating layer of the facade | 2300 |

| Galvanized welded mesh | 6×6, Ø 0.6 mm | 1×15 | Increased strength, resistant to precipitation and sunlight | 1110 |

| Galvanized welded mesh | 10×10, Ø 0.8 mm | 1×15 | For rough façade plasters 3–5 cm thick | 1330 |

| Galvanized welded mesh | 25×25, Ø 1.0 mm | 1×25 | For strengthening facade walls, universal use. Hot galvanizing of wire, minimum coating thickness 20 microns | 1770 |

| TsPVS mesh | 20×20, Ø 0.5 mm | 1×25 | All-metal expanded metal. It has an increased contact area with the façade plaster solution. | 580 |

KREPIX 1800 5x4mm

Plaster mesh TsPVS

Modern facade mesh

Prices for construction reinforcing mesh

Construction reinforcing mesh

How to choose the right mesh for wall reinforcement

The choice of material depends on various factors:

- composition of the plaster mixture;

- material of plastered structures;

- plaster thickness;

- operating conditions.

To reinforce cement-based plaster mortar, a mesh that is resistant to alkalis is selected. When using gypsum solutions, any reinforcing material will do.

It is not economically feasible to use heavy-duty, expensive imported reinforcing materials. It is better to opt for domestic meshes, which are not inferior in technical characteristics to foreign analogues.

Benefits of fiberglass reinforcement

Fiberglass reinforcing mesh is ideal for plastering walls inside and outside buildings for various purposes. Its advantages:

- has excellent adhesion to structures made of various building materials, all plaster and putty compounds;

- withstands heavy loads;

- resistant to aggressive atmospheric and chemical influences;

- protects the plastered surface from the formation of cracks.

- a large assortment allows you to choose any material to reinforce plaster of different thicknesses;

- the lightness of the material allows it to be transported in any car, while saving on transportation;

- does not pose a risk of injury during installation, unlike metal analogues;

- easy to cut and install.

Advantages of steel

Reinforcing plaster with metal mesh has become very popular due to the many advantages of the material:

- high strength, allowing to withstand heavy loads from thick plaster layers;

- Possibility of use on any base, except for structures made of plasterboard and hollow brick.

- You can even plaster metal by welding a steel grate to it;

- permissible plaster thickness is up to 50 mm.

Metal mesh fixation technology

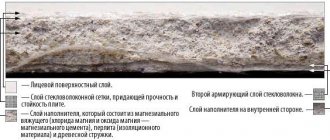

Metal mesh is used only for cement-sand facade plasters; foam insulation is not finished with it. The reason is the small thickness of the screed on foam boards. But a metal mesh cannot be aligned with such precision; it must be pressed down with a thick layer of mortar. Metal façade reinforcing mesh can withstand great forces; it is used when it is necessary to apply a thick layer of plaster on an uneven base.

Metal facade reinforcing mesh

The algorithm for fixing it has several features, the implementation of which guarantees the expected effect. The mesh can be laid in both vertical and horizontal stripes. This does not matter for the strength of the plaster; decide for yourself how it is more convenient for you to work. How to properly fix a metal mesh to a façade wall?

Plaster metal mesh

Step 1 . Take the dimensions of the wall and cut the metal mesh along them. Select a cutting tool based on the wire diameter. A universal tool – metal scissors.

Metal scissors

If they are not there, then a thin mesh with a wire diameter of up to 0.8 mm can be cut with ordinary scissors. True, after this these scissors will have to be sharpened; they will no longer cut paper.

Prices for construction scissors for metal

Metal scissors

Step 2. The metal mesh can be fixed with dowels; the length of the hardware should ensure strong fixation. For facade walls made of foam blocks, you can use ordinary nails 80–90 mm long. They are easily hammered into blocks with an ordinary hammer, and working with them is much faster and easier. Nails are much cheaper than dowels, and the quality of fixation is no different. Use dowels only on brick or concrete facade walls.

Fastening to brickwork using a self-tapping screw with a wide washer

Step 3. Using an electric drill with a hammer drill, drill the first hole for the mesh. The depth of the holes should be several centimeters greater than the length of the plastic part. Otherwise, it is impossible to insert the dowel to the required depth - the hole fills a little with brick chips during drilling and reduces its effective depth. It is difficult to remove it from there; it is better to drill more.

Important. The height of the protruding part of the dowels should not exceed the thickness of the plaster mortar. Monitor this parameter over the entire area of the façade wall so that you don’t have to adjust the dowels during plastering.

Step 4. Drill holes along one line at a distance of about fifty centimeters, hang a mesh on each dowel. Pull it a little, do not allow large irregularities. The position of the line does not matter; it can be vertical or horizontal depending on the method of fastening the reinforcing metal mesh.

Step 5. Check the position of the opposite edge of the grid; if it lies unevenly, then move the grid onto adjacent cells.

Fastening the plaster mesh - diagram

Step 6. Everything is fine - continue to fix the mesh, install the dowels in a checkerboard pattern. Most metal mesh is one meter wide; to secure it you will need three rows of hardware.

Fastening metal plaster mesh to a brick wall

Fastening metal mesh to the wall

Important. Where two rolls overlap, install the dowels at a distance of approximately 10 cm from the edge. Two strips of reinforcing mesh will be hung simultaneously on these dowels.

Step 7. In the areas of window and door openings, the mesh is cut to size. But there’s nothing wrong if you don’t cut it off, but simply bend it. Just make sure that the edges of the bent sections do not protrude beyond the thickness of the plaster layer.

When plastering such a façade wall, the mortar must be applied in several stages. For the first time, the mass should be slightly thicker than for final leveling. Specific values depend on several indicators and are determined individually, taking into account the practical experience of the master. The consistency of the solution is influenced by the weather, the ability of facade walls to absorb moisture, the linearity of the wall, the maximum parameters of unevenness, etc.

The process of plastering a wall using a fixed metal mesh

What kind of technology

Reinforcement is an integral building material. Reinforcement strengthens structures and also extends their service life. When finishing structures, they often encounter defects that are difficult to hide. The only way out is to apply a thick layer of plaster. To ensure adhesion and strength of the coating, reinforcement is used.

It is recommended to use in cases where the coating layer exceeds 2 centimeters. Different materials are used for reinforcement. It is attached using the same technology. All that remains is to decide when it is better to use mesh for plastering walls, as well as which material to choose.

Why and when is it used?

Plaster mesh for interior work is used to solve various problems:

- Elimination of irregularities. After building a house, we are often faced with uneven structures. This is especially true when construction work is carried out by inexperienced specialists. To remove defects, plastering is carried out. If the layer is large, then you cannot do without reinforcement. Otherwise, the plaster will swell and peel off. The use of reinforcement will increase the strength of the coating.

- Increased adhesion to the structure. Compliance with all rules and regulations allows you to build structures that are even. Reinforcement with mesh for walls will ensure reliable adhesion of the cement-sand mortar.

- Repairing cracks. Plaster mesh allows you to eliminate cracks in the structure. The technology eliminates the emergence of new defects that negatively affect the strength and integrity of the coating.

Reinforcement with mesh for plastering walls is an integral process in creating a durable finish that will last for years.

Step-by-step instructions for fixing plastic mesh

The durability of its operation largely depends on the correct implementation of recommendations for installing plastic reinforcing mesh on foam insulation. In all cases, do not rush, work carefully. We have already mentioned that there is no need to reinforce the entire wall height; it is enough to protect only the lower vulnerable area. But these are our recommendations; if you have doubts, protect the entire surface of the façade wall.

Fiberglass mesh

Any brand of glue is suitable for gluing the mesh. Study the instructions, it should have high adhesion to plastic materials. In most cases, a finishing layer of adhesive several millimeters thick is applied over the plastic reinforcing mesh. The final coating is done with facade paints or a thin layer of decorative plaster.

Glue for gluing fiberglass mesh to the facade

Step 1. Inspect the surface of the slabs. If they were fixed with dowels, then completely recess the caps and seal the recesses. You can close the gaps at the same time, but this is not necessary. The fact is that the cracks will automatically close during the application of the first layer.

Fastening sheets using umbrella dowels

Step 2. On the wall, draw a horizontal line along the height of the reinforcing layer. It will help you monitor the height of glue application. A thin layer of material dries quickly, and this not only causes an increase in material consumption, but also negatively affects the final leveling of the layer for painting.

Step 3: Prepare the glue according to the manufacturer's instructions. Always pour water into the container first, and then add the dry mixture. This technology will greatly simplify the mixing process. You can mix it manually with a trowel or using a mixing attachment for an electric drill.

Preparation of glue

The second method is not only easier, but also more effective. You need to stir for a few minutes, and then leave the mixture to stand for another 5-6 minutes. During this time, the moisture will be evenly distributed throughout the entire volume, and the smallest dry lumps of glue will completely disappear.

Step 4. The glue is applied to the wall with a spatula; the longer it is, the smoother the resulting surface is. Professionals work with spatulas up to 70 cm in size; beginners can initially use shorter ones.

Practical advice. If you are just learning how to apply glue to a surface, it is better to immediately get used to working with both hands. If one gets tired, use the other hand. Believe me, it is not so difficult, you just need to show a little endurance and patience.

Apply glue to the spatula with a trowel in the center of the tool. The quantity will be determined experimentally. While applying the layer, hold the spatula at an angle to the foam boards and press with medium force. Achieve a layer thickness of approximately 2–3 millimeters. Do not prepare a large amount of surface at once; for beginners, two meters in length is enough. If you do not have time to fix the mesh, the glue will harden, you will have to remove the old layer and make a new one.

Step 5. Try on the location of the plastic reinforcing mesh. If it does not fit into the window opening, trim the material.

Step 6. Glue one end of the mesh, align it horizontally to the length of the prepared section of the wall. Make sure that the mesh lies smoothly without distortions or bends; be guided by a pre-drawn line on the foam.

Practical advice. The mesh should overlap approximately ten centimeters. You may come across recommendations not to apply glue to the overlap of one line, but to do this simultaneously for two rows. We do not recommend doing this, it only complicates the work. Glue the first row of mesh along the entire width at once, including the overlap. The second line will be glued on top of the freshly applied glue. This method simplifies the fixation of the mesh and has a positive effect on quality.

We attach the mesh with overlapping fabrics

Step 7. Use your hand to press the mesh onto the fresh glue in several places and check its position again.

Cut off the excess

How is fiberglass mesh attached to polystyrene foam?

Step 8. Using a spatula, begin to press the mesh to the surface of the insulation. Make sure that the glue of the first layer extends over the entire surface and evenly covers the mesh cells on the front side. If there are areas where the adhesive is not thick enough, reapply it over the reinforcing mesh. Such omissions may appear in inexperienced craftsmen. Over time, you will learn to determine by eye the optimal thickness of the glue and there will be no more gaps. Spread excess solution over free surfaces. You shouldn’t try to immediately make the surface perfectly smooth, but you need to strive for this result.

Gluing the mesh

Gluing the mesh with a spatula

Step 9. Allow time for the glue to dry. It is better to leave it overnight; finishing grouting of surfaces is recommended the next day.

That’s all the technology is, the surface of the façade wall is prepared for painting or finishing with other materials. We remind you once again that plastic reinforcing mesh on insulated facades is not used to prevent cracks on the surface of the adhesive, but to prevent mechanical damage to the foam. Keep this in mind when making your decision.

Prices for popular types of putty

Putties

How to properly reinforce a screed

Proper reinforcement is carried out in compliance with the rules and technologies:

- The mesh must be in the body of the concrete, so it is laid on prepared cement or plastic supports;

- The reinforcing material should not prevent the penetration of the mixture;

- When pouring concrete, it is not allowed to contain voids in the screed mass to prevent the penetration of moisture and air into the reinforcing mesh;

- The grids must be laid with an overlap of at least one cell.

- The presence of grease stains, paints and rust that would interfere with the adhesion of the mesh to the concrete is not allowed.

Facade mesh to protect construction sites

Compliance with safety regulations during construction work on multi-storey buildings is one of the main requirements for all developers. This is especially true for facilities built within cities. The façade mesh is fixed to scaffolding and prevents construction debris and tools from falling onto pedestrian walkways. For such purposes, the cheapest plastic reinforcing mesh is used; after dismantling, it is suitable for direct use.

Construction mesh

Facade mesh (half-sleeve mesh)

"Emerald" - a new mesh for scaffolding

Question answer

Is it possible to repair peeled areas with façade reinforcement mesh? It is possible, but it is better to avoid such situations. Unfortunately, in most cases, peeling appears several months or years after finishing the insulated façade walls.

Repair of peelings

How is the repair done?

- Inspect the peeled area. Using your hand, check the strength of the mesh fixation next to the detached area. Prepare materials: glue and a piece of plastic reinforcing mesh. If the facade walls are painted, then you need to have the appropriate paint.

- Pull the peeled mesh towards you and use a sharp mounting knife to cut it around the perimeter. Work very carefully, do not damage the foam. If the sect continues to flake off during cutting, great. In this way you remove the entire problem area; in any case, it would peel off over time.

- Cut a new mesh for the patch, the size should be slightly larger than the cleared area for the overlap.

- Remove the layer of old glue from the surface of the foam.

- Using a spatula, carefully remove the top layer of glue from the surface of the remaining mesh to the width of the new overlap. Apply the first layer of glue, embed the mesh into it and apply the second layer of glue.

- After it dries, level it. Pay special attention to the docking area. It should be as smooth as possible without sudden changes in height.

Repair of a peeling area

How does the quality of plastic mesh depend on its price? Almost nothing. When choosing a mesh, pay attention to the thickness of the fabric and the size of the mesh cells. All other characteristics are nothing more than advertising gimmicks of the manufacturers.

Plastic mesh

What is better than a plastic anti-corrosion coating for metal reinforced mesh against galvanizing? Nothing, besides, the price of such a mesh is higher than with galvanized wire. You need to know that the adhesion of all cement mortars to plastics is significantly lower than to galvanized surfaces. As for the service life and load-bearing capacity, these indicators are absolutely identical.

Metal mesh with polymer coating

Is it possible to do without reinforcing mesh when plastering uneven façade walls? Not only is it possible, but it is necessary. We have already talked about simpler and more effective methods of working with such surfaces. Reinforcement with metal mesh is used not to prevent the appearance of cracks, but to increase the bearing capacity of cement-sand mortars. It is needed when screeding the floor. One more nuance. The indicators of linear thermal expansion of metal and solution differ significantly. This means that microcracks will certainly appear in the places where cement and metal mesh meet, because outside temperatures fluctuate within significant limits. In enclosed spaces there are no such fluctuations.

Should I use reinforcing mesh on the basement surfaces of façade walls? Use this technology only for foam-insulated bases. In all other cases it is not needed.

Photo - a cake made of insulation and mesh for reinforcement

How much does the cost of finishing facade walls increase due to the use of reinforcing mesh? The cost of finishing increases by no more than 3–5%. But if we take into account possible repairs due to mechanical damage to the foam, then a slight increase in cost is completely justified.

When is mesh used for plastering walls?

To determine the need for reinforcement and select the appropriate material, you need to measure horizontal and vertical deviations using a two-meter rod.

Reinforcement of plaster is necessary when the layer thickness is more than two centimeters. With a smaller thickness, the solution will stick on its own.

Regardless of the layer, it is necessary to strengthen the plaster with a reinforcing mesh when finishing surfaces made of cellular concrete.

Plaster, 2-3 cm thick, can be reinforced with a mesh made of polymers or fiberglass.

If the thickness is more than three centimeters, a metal grid will be required.

It is not recommended to apply plaster thicker than five centimeters. For large deviations, it is better to level the walls using plasterboard sheets.