Now private construction is gaining enormous popularity. If you have ever been involved in the construction of a wooden house, then you know very well that to build any living space made of wood, you need a good quality log house.

- Excessive moisture in the material

- Impregnations with antiseptics

- Wood bleaches

- Wood preservatives

- Procedure for applying protective agents

- Methods for applying protective compounds

To build a bathhouse or house, you will have to put a lot of effort and patience. Before starting construction, you need to prepare materials. This mainly applies to the logs from which the log house will be made.

The problem of excessive timber moisture

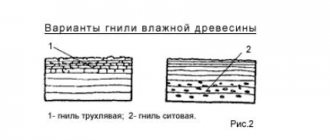

Wood is a living material, and even after cutting down the tree itself, biological processes in it do not stop . Unfortunately, one of these processes is rotting.

Professional builders know very well that a log house requires wood that has been dried to the required moisture content. However, the main problem is that the house is not built in one or two days. However, lumber, logs and other lumber are usually stored in an area where they can be exposed to the environment: rain, hail, wind or simply heat and humidity.

All these conditions increase the level of moisture in the wood, and rotting processes begin to develop there. Because of this, it is urgently to treat the materials with anti-rot agents, because the fungi that cause this process feed on substances contained in the wood and gradually destroy its structure.

There are a lot of products that protect wooden materials from rot and mold, all of them can be divided into 3 types :

- impregnations that contain antiseptics;

- bleaches;

- preservatives

What is their difference? In methods of exposure and methods of application.

Work technology

Preparatory work

If you decide to paint or varnish wooden wall cladding, then the instructions given in this section will help you understand the nuances of the technology.

Work must begin with surface preparation:

- If the boards were previously painted or varnished, then the old coating must be removed. We soften the painted layer with warm water or a stream of hot air from a hair dryer, and then remove it with a spatula.

- We remove the remaining paint and varnish using a sanding machine.

- If we process new wood, then it needs to be sanded all the more. To do this, we successively use several abrasive materials, gradually reducing the grain size - this way we get a perfectly flat surface.

The surface must be sanded before painting or varnishing.

Advice! If there are defects on the sheathing, then before sanding they must be masked by using a small amount of wood putty. After waiting for the putty to dry, we clean the area with sandpaper, and then sand the surface.

- After filling and sanding the wood, it makes sense to treat all surfaces with a penetrating antiseptic water-based primer.

- Apply the primer in one or two layers, making sure that the wood does not get too wet.

- After the primed surface has dried, the lining inside the house can be painted or varnished.

Putty for filling defects

Application of the composition

Both painting and varnishing can be done with your own hands.

The process itself is not complicated, but there are still a few recommendations that are worth listening to:

- Having decided how to treat the wood inside the house, it is worth purchasing the selected composition with a small margin. The thing is that the shade of paint or tinted varnish may differ in different batches, so it is better to paint everything with one material.

- Before starting work, mix both paint and varnish thoroughly. This is done in order to compensate for the delamination of components that occurred during storage.

Apply varnishes and paints with a brush in several layers

- To apply the composition, use a wide flat brush. We will also need a narrow brush on a long curved handle - we will use it to penetrate hard-to-reach places.

- We apply both paint and varnish in several layers. The more layers and the smaller their thickness, the better the result.

- The direction of the strokes should be perpendicular. So, for example, we apply even layers vertically, odd ones horizontally, or vice versa.

- After applying each layer, you need to dry the surface. Drying time depends on the type of composition used, so you need to plan the work individually.

We dry the treated surfaces at a constant temperature without drafts.

And most importantly, during drying, the fresh layer of finishing should be protected from exposure to drafts and temperature changes, otherwise the coating will quickly begin to crack and peel off.

Impregnations with antiseptics

The latest impregnations protect wood from damage and destruction. They work as follows: they fill the pores and small cracks of the wood with special chemicals, so that neither fungi, nor mold, nor insects can feast on your log house. Creosote is considered the most effective ; it is used to treat railway sleepers and edged lumber. However, this impregnation is too toxic for people, and it is dangerous to use it at home. But the market offers a huge number of modern products (for example, the Prosept and Neomid brands) that are safe for humans.

Let's look at the main types of modern wood impregnation products:

- Saline . They come in the form of a powder that needs to be diluted with water and ready-made liquids. They provide comprehensive protection and protect wood from mold and fungi, and also protect it from fire. For use on external cladding only. But this type of impregnation should never be used in combination with a metal roof, since the salt in the composition will lead to rust and corrosion.

- Water based . The most inexpensive and frequently used. Absolutely harmless (thanks to this, they can be used both inside and outside the house). The main task is protection from moisture, so they are often used together with salt impregnations so that they do not wash out.

- Solvent based . Quickly penetrate the wood structure and protect throughout its depth. They protect not only from fungus, but also from fire, and also protect from moisture and exposure to the sun. But you need to work with them carefully, preferably in a respirator or outdoors due to their toxicity.

- Based on linseed oil . They protect wood from moisture and cracking and are the most effective. But the layer of such impregnations needs to be renewed frequently, which is the main disadvantage.

Antiseptic treatment of a wooden house is usually carried out before applying a coat of paint.

Recommendations for internal processing

Treatment of wooden surfaces indoors begins with the lower elements of the house, which are more susceptible to moisture than others, since they are in close proximity to the ground. First of all, logs, subfloors, and lower floors are treated. Then they begin to process the main parts of the wooden structure: walls, ceilings, floors, partitions, etc.

Before processing wooden lining, timber or logs, it is necessary to prepare the surface. If the walls of the house have old paint, it must be removed. To do this, first the surface is heated until the paint softens, and then it is removed with a scraper.

Next, the wood is sanded and polished using a sander or grinder. Sanding is necessary for any lumber: logs, lining, imitation timber, etc. After sanding, the pores of the wood open, which better absorb processing agents.

An antiseptic is applied to a dry and pre-dusted surface. For interior spaces, one coat is sufficient. But for a bathhouse or an unheated house, one layer will not be enough. Such premises are treated twice.

The next treatment is carried out with fire retardant impregnation. It is better to coat the internal elements of the house with a non-salt fire retardant.

The last stage is priming the surface, after which any decorative coating can be applied.

accepts applications for professional processing of wooden houses. Protective treatment inside the house is carried out with certified preparations that are completely safe for humans.

You can check all the details of your order with our specialists at the coordinates located on the “Contacts” page.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Wood bleaches

Bleach is used to treat already infected wood and prevent it from darkening. They come in different types; in Russia they usually use chlorine, oxygen, oxalic acid-based and combined ones. Their task is to neutralize the infection and decay that has begun. It must be remembered that even high-quality wood materials that have been dried and processed in a factory can develop fungi if they are stored outdoors. However, this may not affect the appearance. But the wood will continue to deteriorate after construction. Therefore, experts recommend treating all materials that will be stored for a long time with bleach for prevention.

Advice from experts

The quality of processing of the walls of a wooden house largely depends on the material used. It must be safe, high-quality, powerful, long-lasting and preferably inexpensive. There is a wide range of antiseptic compounds for protecting log houses made of rounded logs on the construction market. Manufacturers of these compounds are both domestic and foreign.

As practice shows, Russian formulations are not inferior in quality to imported ones, because The materials used for the manufacture of the compositions are almost the same. Despite this, the cost of domestic antiseptics is much lower, because there is no need to overpay for the export of goods. Among Russian antiseptic protective compounds, you can purchase them for processing rounded logs from the manufacturers Neomid or Prosept.

Wood preservatives

These substances cover the wood with a thin film and protect it from moisture penetration, because a humid environment is ideal for the occurrence and proliferation of fungi and mold. In most cases, wood is treated with preservatives after the above remedies. But, depending on the type of preservative, they are used before painting, sometimes as a primer. And also many azures, paints and varnishes already contain preservatives.

Procedure for applying protective agents

- The wood needs to be sanded (especially if you are working with an old log house), this will allow you to get rid of cracks and irregularities:

- First, the wooden house is treated with an antiseptic in 2-3 layers.

- Each layer is applied after the previous one has dried. The entire surface of the tree must be covered.

- Products containing preservatives are applied. The ends are covered with 4-5 layers, and the sides with two.

- The primer, which contains bleaches, is applied both inside and outside.

To ensure that your home does not suffer from weather conditions and insects, treat it every 5-7 years.

Processing sequence inside the house

Primary processing of lumber usually takes place at the production stage. If you purchased untreated logs, you need to process them yourself before building the house. For this purpose, special transport impregnations are used; usually their validity period does not exceed eight months. Thus, these means provide protection for logs only during the construction period.

After construction is completed, the effect of the antiseptic has already expired, and the house remains unprotected. This is a very difficult period for a wooden house; it will have to go through a long process of shrinkage, which lasts from six months to two years. How to protect a log house during this period? At this time, a second protective treatment of the log house inside the house must be carried out. For re-processing, products are used that provide complete protection from any natural factors, but at the same time do not interfere with the air exchange and shrinkage processes taking place in the wood.

After the structure has undergone shrinkage, the main finishing work is carried out, including complex internal treatment of the wooden house with protective impregnating compounds. Then the treated log house can be painted, varnished, and decorated with decorative materials.

The above processing steps are suitable for a new home. As for old buildings, they must be treated at least once every five years.

Methods for applying protective compounds

The method of application depends on what protective agent you will use to treat your log house. There are different coating methods.

- Using a roller or brush . If the mixture is so thick that it cannot be sprayed, this method is ideal (treating a wooden house with an antiseptic). But this is one of the most difficult options.

- Spraying using a spray bottle (for aqueous solutions). This procedure is carried out in a respirator and safety glasses, since many protective products contain toxic substances.

- Immersion of materials in baths with a special solution (suitable for salt impregnations).

You can purchase high-quality products for processing wood from which log houses will be built in the future, and protecting it from destruction and insects from our company; we are the official supplier of impregnations, bleaches and preservatives “Neomid” and “Prosept”.

To find out the availability and cost of the funds you are interested in, you can call us.

Calculation of processing costs

The cost of processing depends on the type of wall material and the dimensions of the building. The most susceptible to rotting are timber with natural moisture and simple logs. Walls made of these materials will require very expensive processing. The least amount of money will be spent on processing structures made of laminated wood, which are initially protected with an antiseptic applied at the factory. The current condition of the structure should also be taken into account to determine the cost of treatment. If the house is already affected by rot, then measures to eliminate the lesions and prevent the further spread of microorganisms can cost a lot of money.

To roughly calculate the cost of processing wooden walls, it is necessary to determine their area. It is known that to treat walls with an area of 100 square meters. m you need to spend about 10 liters of antiseptic drug. The average cost of this volume is about 10 thousand rubles. To this should be added the cost of the film-forming composition. If such processing is carried out annually, the costs are quite significant.

In addition to preventive treatment of wood, there are radical methods associated with making changes to the structure of the building. For example, if there is an intense fungal attack, it may be advisable to completely replace the damaged wood.