Cork is obtained from the bark of a certain type of oak tree. Trees of this type grow mainly in Africa. Since ancient times, cork has been used in various spheres of human activity. The building materials industry produces a material called cork backing.

The main purpose of the underlay is to serve as a lining under floor covering structures (laminate, parquet, linoleum, carpet and vinyl). However, people have long noticed that a cork backing glued to a wall can perfectly serve as wallpaper.

Why are cork coatings attractive?

Cork is a natural material that naturally fits into the human world around us. This is a clean, environmentally friendly product.

Qualities such as soundproofing, very low thermal conductivity, and aesthetic appearance are crucial in using cork backing on walls instead of wallpaper.

To convince the reader of this, we present a table of the quality characteristics of cork:

| № | Technical characteristics of the plug | Unit measurements | Indicators |

| 1 | Density | Kg/m2 | 220-250 |

| 2 | Thermal conductivity | W/m2 | 0,042 |

| 3 | Sound insulation coefficient | – | 0,85 |

| 4 | Sound absorption | Decibel | 12 |

| 5 | Humidity threshold | % | 7 |

| 6 | Tensile strength | Kg/cm2 | 2 |

| 7 | Chemical resistance | – | Inertia |

Why are we talking about cork backing when there are special cork wallpapers on sale. The thing is that wallpaper made from this material costs 3-4 times more than the backing.

The backing is a very durable material and will serve the owners until they get tired of it. Over the years, the material retains its appearance and practically does not age. Minor mechanical impacts do not leave any traces. This happens due to the elastic structure of the cork.

Wallpaper from the backing can be easily dismantled and re-glued to a new location. At the same time, the material does not change its technical characteristics.

History of cork

Cork coverings came to the world of interior design relatively recently. But already before our era, the versatility and quality of cork oak bark were noticed. Then shoes, barrels, floats, and lids for vessels were made from this material. The corking of wine bottles, according to legend, dates back to the days of a monk named Dom Pérignon, although this is a controversial point, since there is evidence of the use of corks for this purpose by Spanish sailors and the Duke of Bedford in 1665. It was only in the 18th century that the Portuguese were the first to use cork oak bark as a building material, covering their homes with layers of bark from this tree. Their Capuchin monastery is especially famous, the walls and floor of which were already covered with cork.

In Europe, cork began to be actively used for finishing residential premises only at the beginning of the twentieth century. In Russia, it became known only about 15 years ago, and its popularity among other building materials is rapidly growing.

Required tools and materials

As in any type of activity, before starting work, prepare and check the availability of the necessary tools and materials:

- pencil or felt-tip pen;

- metal ruler 2 m long;

- square;

- roulette;

- rags;

- fine-toothed spatula;

- solvent;

- masking tape;

- sharp construction knife;

- gloves;

- cork glue.

Preparatory work

Before proceeding directly to finishing the walls with cork, it is necessary to carry out a number of preparatory operations.

- The walls are checked for evenness. Dents and cracks are repaired with putty.

- All surfaces for pasting are treated with primer.

- The location of the substrate sections is marked on the walls.

- Since the backing rolls are 1 m wide, it is most convenient to cut the main sections of wallpaper 1.5 m long. That is, each main fragment of the coating will cover a wall area of 1.5 m2.

- When the number of main sections of the substrate is determined, then the sizes of additional fragments will be visible from the markings.

- If all the work is carried out in the same room where the pasting will be done, then to cut the rolls of backing, lay a sheet of fiberboard or other dense material on the floor.

- The rolls of the substrate are unrolled and laid on the floor. To give the material the appearance of a horizontal plane, large, heavy planes are laid on the cork. For example, a dining table is placed on unfolded rolls of wallpaper with the tabletop down. In general, the main goal is to withstand the plug under load for 12 hours, or even better - a day.

- Then they proceed directly to cutting the substrate. This is done using a metal ruler, a square and a knife.

Pasting walls with cork backing

The work of gluing cork to walls consists of several stages:

- Open the container with ready-to-use glue. The glue is thoroughly mixed until a homogeneous mass is obtained. This can be done with any clean rod.

- Apply a layer of glue to the wall using a notched trowel. The viscous mass is leveled with a spatula so that the thickness of the glue is about 1.5 mm.

- Pasting begins from one of the upper corners of the wall.

- Apply masking tape along the perimeter of the marking of the first section of wallpaper. This is done so that when leveling the cork on the wall, excess glue does not stain the adjacent surfaces.

- A piece of wallpaper is glued to the fenced area.

- After this, they proceed to covering the adjacent section of the wall with glue. At the junction of two sections, remove the masking tape.

- When joining adjacent sheets of cork, the released glue is immediately removed with a rag.

- It is advisable that the vertical seams of adjacent rows of wallpaper sections be made staggered.

- After the main large fragments have been glued, they proceed to gluing small finishing sections of the substrate. To learn how to properly stick a cork on a wall, watch this video:

Tips for working with cork

You need to keep an eye on the sharpness of the blade

Cork wallpaper can be glued both horizontally and vertically without much effort. But what if, for example, you chose not rolled wallpaper rolls, but a cork tile covering? There is nothing complicated here either. The adhesive composition is applied similarly to rolls of wallpaper, only they must be laid on the surface of the wall according to the same principle as ceramic tiles are laid. And this can be done in several ways: diamonds, staggered, evenly or along the diagonal. The choice is up to you. Just do not forget that it is necessary to form at the stage of preparation work, and not specifically before gluing.

Another quite important nuance is cutting wallpaper rolls. For those who start wallpapering, this is a major headache. To make your task easier, do not forget: the key tool for such work must be a repair knife with replaceable blades. As already mentioned, cork is a very brittle material, so cutting it requires a very sharp knife. Due to this, you will be able to minimize material tears. As soon as you feel that the blade is dull, break it off and continue working. When you need to create any cutouts, for example, for sockets or switches, we recommend using one template. If you need a cutout for a socket, use a socket box.

Rolls of wallpaper, which are covered with wax on the front side, look great, but they can be spoiled by traces from your fingers, since everything is clearly visible on them. What should you do if, for example, you still get them dirty? For this you will need a hair dryer. You need to slightly warm up the place that you “marked”, and the wax will soften under the influence of heat. Then all traces will be healed. But if the cork is dirty with dirty or dusty hands, it cannot be reconstructed at all, it can only be replaced. Therefore, when working, use gloves or wash your hands frequently to avoid various types of contamination.

Minor repairs to cork surfaces

When pasting with cork, minor damage to the surface of the wallpaper is possible. We will give you a little advice on how to solve this problem:

- take a small piece of wallpaper and finely chop it with a sharp knife;

- then the resulting mass can be ground in a meat grinder or use an old coffee grinder;

- the crushed mass is mixed with PVA glue;

- Using a spatula, fill the damaged cork surface with a viscous mass. Watch the intricacies of working with cork in this video:

Traces of such repairs are almost impossible to notice.

Walls made of cork wallpaper are usually varnished. They do this twice. The first rough coat of varnish acts as a primer. The second layer forms the final glossy surface of the wallpaper.

Cork panels are produced in the form of wallpaper with or without paper backing, as well as in the form of slabs. Wallpaper that does not have a base is fragile to break and is not durable in general. Therefore, you should not work with such materials yourself; it is better to entrust this to specialists. To glue paper-based canvases and slabs on your own, it is important to choose the appropriate wall adhesive for cork.

Types of material and its advantages

Wallpaper made from cork

Cork wallpaper is an expensive pleasure. However, the price is justified by environmental friendliness, high performance qualities, long service life and excellent decorative effect. You can find products cheaper, depending on the reputation of the company that creates the material, the type of coating and the base used.

If we talk about the types of cork material, then there are several of them. This:

- baseless rolls of wallpaper;

- rolls of wallpaper with a base.

Baseless

Rolls of wallpaper without a base are much more expensive, but are completely environmentally friendly. During the manufacture of this wallpaper, glue is not used as a binding material. But how do particles connect with each other? When the cork is heated, the resinous substances that are located in it melt, bonding the crumb particles together. Such products are quite dense, but at the same time have low fracture strength. Because of this, you need to be quite careful when working with such rolls of wallpaper.

Production of wallpaper rolls from cork

Rolls of wallpaper with a paper base are much cheaper. This is a more affordable and popular option. Their production consists of gluing cork veneer onto a paper base. It is much easier to glue such wallpaper to the surface of the wall, because it is not very easy to spoil it. You can completely do this kind of work yourself.

The development of gluing rolls of paper-based cork wallpaper is practically no different from the process of gluing ordinary rolls of wallpaper.

Such wallpapers mainly serve only a decorative function. Due to the small thickness of the product, they do not have insulation and noise protection parameters. Their advantages are that they are more affordable, light weight, some are already coated with wax or varnish, and they can also be glued not only to walls, but also to the surface of the ceiling.

Certain types of paper-based cork wallpaper do not require any adhesive to be applied to them before gluing. The thing is that to gluing you only need to remove the protective film and glue the rolls of wallpaper onto the wall surface.

You can purchase the material in a special store. Wallpaper rolls can be:

- Rolled.

- Tiled.

Cork tiles

The material in a roll is sold in reels that have a width of 30, 60 or 100 cm, a length of 10 m. The thickness of this wallpaper is 3 mm. If we talk about tile products, in most cases they have a classic size - 30×30 cm or 60×60 cm. Knowing these parameters, you can easily calculate how much material you need to cover the walls.

It is worth noting that the material from the plates can be single-layer or double-layer. The final look is characterized by the fact that its bottom layer is often painted, and the top layer consists of compressed cork granules. Due to this, the layer on top appears to be illuminated and has a certain tint, which gives the material individuality.

It should be noted that anyone can choose the material to their liking, since the products have different textures, patterns and colors. Decorative cork can give your home an original look.

But why is covering walls with cork considered not a cheap pleasure? Because of my own working qualities. What are they?

- Cleanliness in environmental terms.

- Comfortable sizes.

- Availability of a protective coating (varnish or wax).

- Long service life, 20 years or more.

- Resistance to impacts, scratches and so on.

- Normal care, when you can use any cleaning products.

- And they do not cause allergies and will not absorb unpleasant odors.

- Rolls of wallpaper without a base have good thermal insulation and sound insulation properties.

- With their help, you can hide flaws on the surface of the walls: curvature and unevenness.

- Can be used for ceilings and floors.

Looks nice in the interior

As you can see, using cork for finishing work in your home is much more profitable. So, having learned everything about the cork, we begin specifically to work on pasting the room.

Glue characteristics

Cork is the bark of a cork tree that is removed from it from time to time. This material has a long service life, is resistant to moisture, and has excellent sound insulation characteristics.

Despite its many advantages, cork is a fragile and expensive material. If you manage to become its owner, then you should think about a high-quality and heat-resistant adhesive composition (cork retains heat excellently).

There are currently two types of glue designed to work with cork:

- Universal acrylic.

- A contact adhesive composition that is used to treat both surfaces being joined (most often used).

Important! Many people are interested in whether it is possible to glue a cork with PVA glue. Such a composition is not suitable, since the material absorbs liquid, as a result of which it swells and deforms.

Main characteristics of contact adhesive:

- unusually strong connection between the wall and the cork covering;

- increased resistance to moisture;

- resistance to acids and alkalis;

- resistance to high and low temperatures.

Instructions . How firmly the surfaces will be connected depends on time: it is enough to press them together for 20 seconds; with longer pressing, the connection will be stronger. For high-quality adhesion, the glue must be applied to dry and clean walls, the air temperature should be from +15° C, and the humidity should be below 75%.

The use of cork coverings in the interior

In addition to walls, cork can be used to install floors, ceilings, and furniture, and it will look no less modern.

Floors. In order to cover the floor with cork, there is no need to remove the previous covering. Linoleum, laminate - all this can be left in place. You can assemble a floating cork floor very quickly, like a puzzle, and if you move, you can assemble it in reverse order and take it with you. Such floors do not absorb dirt, do not collect dust, can withstand heavy furniture, are useful for people with joint diseases, do not cause allergies, and soften sounds (clattering heels, falling objects).

Ceiling. Cork ceilings are moisture-proof and mold-resistant. The same thing is suitable for covering as for walls: rolled wallpaper, tiles. You can cover the entire ceiling, or you can cover it fragmentarily, as your imagination dictates. Before installation, the ceiling surface should be cleaned of the previous coating.

Brands of cork glue

Currently, many varieties of adhesive compositions designed for cork coatings are produced. Careful study of the characteristics indicated on the packaging by the manufacturer and the annotations will help you make the right choice.

Some types of adhesives contain a toxic base, others are absolutely harmless as they do not emit dangerous fumes. Compositions suitable for a specific type of surface (wood, concrete) are produced.

Glue for cork on the wall:

- Wakol does not contain solvent and is made on a latex-acrylic base. It is not frost-resistant and does not retain its properties at sub-zero temperatures, therefore it is not suitable for use on a balcony or in a country house for seasonal residence.

- DecolVern adheres very reliably and is recommended by cork wallpaper manufacturing companies. A specific smell is felt only during work; subsequently it disappears without a trace.

- Bunitex is a mixture of synthetic rubber and polychloroprene.

- “Moment Cork” provides reliable adhesion, is resistant to moisture, alkalis and acids, frost-resistant, and economical. It is made on the basis of polychloroprene and contains toluene. Excellently attaches cork to wooden and metal surfaces. The composition cannot glue polyethylene, styrofoam, plasticized PVC and polypropylene.

Step-by-step instructions for finishing walls

Although it is better to entrust the finishing of walls with cork to a specialist, you can do this work yourself. Just follow the step-by-step instructions exactly.

Set of tools

Before starting work, prepare the following tools:

- level and plumb;

- assembly scissors;

- iron ruler;

- notched spatula;

- velor roller;

- seam roller;

- container for glue.

A day before starting work, unpack the material and leave it in a warm room to get used to it so that it does not unexpectedly change in size during installation.

Cork glue

Choose glue, preferably contact or acrylic. Using tools, determine the center of the wall, draw lines that will be visual boundaries for the cork material.

Preparing the walls

Although cork material does not require ideal preparation of the wall surface, for the best result the walls will have to be leveled, primed and cleaned of dirt and old material before work.

Fastening

The cork covering is secured using glue. It must be applied in an even layer, then glue the tile to the wall. To avoid bubbles, start from the bottom of the tile, smoothing it thoroughly. Wait for the cork to stick, then go over it and along the joints with a roller.

Gluing cork tiles to the wall

In the corners, near sockets and switches, the tiles will have to be cut.

If you choose cork wallpaper, you must remember that a very thin layer of glue is applied to the paper base, only on non-woven paper it is thicker.

Decoration

At the last stage, decorate. If you plan to make an ornament or pattern, use several cork tiles of different colors. Select additional materials, such as mirrors. Some cork materials can be painted.

Cork on the wall in different tones

Tinted coatings are chosen for rooms that are located on the south side.

Interlocking and adhesive cork materials are widely used in the form of collages of tree species, which will add eco-style features to the interior.

How to glue

Before starting work, the walls are prepared, which includes:

- cleaning the surface from dust, dirt and grease stains;

- leveling (sealing cracks, holes);

- applying a primer that will provide improved adhesion.

Depending on the type of cork material (slabs, wallpaper, rolls), the specifics of the work differ.

Advice! A thorough study of the characteristics of the adhesive and coating, as well as a detailed drawing up of an action plan, will help to perform gluing efficiently and as quickly as possible.

The slabs are mounted, moving vertically, horizontally, diagonally, staggered, in diamond shapes.

To work you will need:

- 2 rollers (rubber and velor);

- a sharp construction knife with replaceable blades or scissors;

- special adhesive composition;

- pencil;

- building level;

- roulette;

- putty knife;

- thin brush.

Instructions for gluing the boards:

- Set the lower level according to which the tiles will be laid. Draw perpendicular lines on the wall to determine the correct location of the first element.

- Mix the glue thoroughly. Apply contact composition to the wall and tiles, acrylic (non-contact) - only to the wall.

- After this, leave the product for 20 minutes to absorb.

- To ensure maximum adhesion of surfaces, run a special comb over the adhesive layer.

- Press the tile against the wall. The glue hardens very quickly, so align the position of the element immediately.

- If air bubbles appear, remove them with a rubber roller. Do not crush, bend or deform the material, as the cork is very easy to damage.

- Place the next tile as close as possible to the previous one. If small gaps have formed between them, coat them with the composition using a thin brush, and then go over them with a dry roller. If necessary, the cork can be trimmed a little.

The adhesive composition completely hardens after 4-6 hours. However, the process can drag on for two days - this depends on the humidity and temperature in the room. After the glue has completely hardened, the coating is ready to be decorated with stone or wood.

Walls

0 votes

+

Vote for!

—

Vote against!

The modern market of wall finishing materials offers more and more new varieties of environmental products. One of the most popular natural materials is cork, which is made from the bark of the cork oak tree, which grows in the Mediterranean countries. Today we’ll talk about the advantages of this material, decorating walls with cork yourself and caring for cork tiles.

- Tools and materials

Features of cork wall coverings

Cork wall covering is made from the bark of the cork tree, which is obtained in the most painless way for the plant. This most valuable natural material is removed from the tree by hand, after which the date is marked. The next time you can get such “clothes” of a tree only after 9 years.

Cork oak lives for about 250 years, and after restoration, each subsequent layer acquires an increasingly beautiful and smooth texture and becomes more valuable. The color range of cork tree bark allows customers to choose many shades: from light yellow to deep brown.

Cork is a unique natural material that has numerous advantages, which are as follows:

- Cork is a natural material, and this is one of its most important positive properties. Dust does not accumulate on cork, it does not have an unpleasant odor, is antistatic and reduces the level of various radiations.

- Cork wall coverings have a low specific gravity. It is even used to make fishing gear, as it is a buoyant material.

- This material is considered to be quite elastic and resilient: after compression, it returns to its original shape due to the presence of flexible cell membranes.

- Cork boards are impermeable to liquids and gases, which is due to the presence of suberin in their structure. Thanks to this, this coating does not rot and mold does not live on its surface.

- The material has low conductivity of heat and vibration due to the presence of gas elements, which are enclosed in microscopic capsules that make up the structure of the cork.

- Cork coverings intended for walls are characterized by great strength: this material is very wear-resistant and has a high level of friction.

- Cork is hypoallergenic and chemically inert. It is safe for health, does not absorb fat, acetone and oil, does not emit harmful substances into the air and does not cause allergies.

- Cork has excellent soundproofing properties, but this requires covering the entire surface of the wall with cork tiles, otherwise the desired effect will not be achieved.

- Cork material, according to most consumers, has excellent thermal insulation properties and helps reduce heat loss. But manufacturers do not claim cork as a complete thermal insulation material. Even the thickest six-millimeter cork tiles will not replace polystyrene foam of similar thickness.

- The plug is quite simple to install and easy to maintain. When installing tiles, no adjustment is required.

The main drawback that many consumers have noted is that cork wall coverings are quite expensive. However, the cost of a cork varies, and anyone always has the opportunity to choose a cork based on the size of their wallet.

Types of cork wall coverings

When choosing cork covering for walls, you need to decide which type of product will be most appropriate in your conditions. This determines, first of all, the decorative effect created by the finishing, the service life of the coating, the complexity of installation and the price of finishing the walls with cork. Before going to the store, be sure to familiarize yourself with the features of the offered assortment on the construction market.

Cork boards

Cork boards are made from granulated cork. They come in one or two layers. When making single-layer slabs, granulated cork is pressed into the desired shape and texture, and then coated with protective wax for additional strength. Typically the substrate is 2 millimeters thick.

When producing two-layer slabs, an adhesive composition based on natural components is applied to the main layer of pressed cork, after which the surface is covered with agglomeronic or natural cork veneer. The base of the slab is very often painted in a certain color, and then it contains colored inclusions. Standard sizes of cork wall tiles are 3 by 300 by 300 and 3 by 600 by 300 millimeters (thickness x length x width).

After applying the decorative layer, the material is coated with protective wax so that it can be used in rooms with low humidity. Nothing will happen to the cork coating itself, because it is not at all afraid of moisture, but the paint and adhesive layer may be damaged. The service life of cork tiles is 10-30 years, depending on the type.

Cork rolls

The next type of cork covering is wall cork in rolls, which is a structure made from a base – a finely crushed and pressed layer of granulated cork and a top decorative layer of cork veneer. The material is produced without the use of synthetic binders. The rolled cork is sold unfinished, and after installing such a cork, the entire surface of the coating is treated with hot wax or varnish to improve the quality characteristics.

Cork in rolls has a smaller thickness than a cork slab - 1.2 - 2 millimeters, due to this it is more elastic and more suitable for combination with other finishing materials, say, wallpaper. Roll coatings are characterized by a large margin of tensile strength, which reaches 2 kilograms per square centimeter.

Rolled cork coverings do not swell and do not come apart during prolonged contact with water, so they are well suited for rooms with high humidity. The service life of coatings in rolls is at least 20 years. Another advantage of cork rolls for walls is the absence of horizontal seams during installation, which allows you to obtain an almost uniform pattern.

Cork wallpaper

Cork wallpaper is the most affordable type of cork wall covering. In their production, they take as a basis a paper web, which is subsequently treated with transparent or colored varnish and covered with thin agglomerated veneer (up to 1 millimeter) of various structures and formats, leaving unfilled areas. Cork wallpaper in modern design harmonizes very well with different finishing materials, be it ordinary wallpaper or just paint.

Cork wallpaper in its strength characteristics is closer to heavy wallpaper - look at the photo of wall decoration with cork. Their structure mainly consists of a large number of pores, so the material has very good sound and heat insulation. This material is lightweight and very elastic, which allows it to withstand significant impact loads. The elasticity of wallpaper and cork makes it easier to work with when pasting.

Cork wallpaper, like all other cork coverings, does not collect dust, does not electrify, which makes its use suitable for residential premises, and is characterized by antibacterial properties. The colors of cork wallpaper include natural tones and various colored inclusions. The service life of cork wallpaper reaches 10 years.

Liquid plug

For exterior wall decoration, it is customary to use the so-called liquid cork, which is not a very common and familiar material for us. The liquid mixture consists of 96% natural cork bark chips and 4% acrylic binder. The material contains millions of tiny pores that are filled with oxygen and nitrogen, contains resins and juice of the suberin plant, which make the liquid plug impermeable to moisture.

A similar composition is applied to the surface by air spraying. Liquid sprayed cork has good adhesion properties to most materials and can be painted in a variety of colors, including bright ones. Using colored cork, you can save on finishing the facade and as a result get beautiful walls. Depending on the purpose, there is liquid cork for facades, roofing and fire-resistant.

Liquid cork can be applied horizontally or vertically, thus leveling certain surface imperfections. The cork layer, which is 3 millimeters thick, perfectly hides almost all technological seams and unevenness of the base, closes shrinkage cracks and microcracks of the facade. It is also customary to use this material as insulation, for noise and waterproofing of a building.

Technical traffic jam

Technical cork is used primarily as a substrate for other types of decorative coatings. Technical cork is made in the form of slabs or rolls of pressed granulated cork without a decorative layer. The rolls have a length of 10 meters, a width of 50 centimeters and a thickness of 1 to 6 millimeters, the dimensions of the plates are 1 by 0.5 meters.

Technical cork, like other materials made from the bark of the cork tree, is a natural material that has a large supply of mechanical strength and excellent sound and heat insulation properties. In addition, this coating is resistant to moisture, insects, rodents and fungus.

One of the distinctive properties of this material is its antiseismicity, that is, its ability to dampen vibrations. Technical cork, depending on the thickness of the coating, can reduce the level of fluctuations by up to 30%. The service life of technical cork material is not limited.

Wall decoration with cork tiles

Modular cork tiles are suitable for cladding walls in any room, including those classified as “wet”. In general, the procedure for decorating walls with cork can be called similar to the process of wallpapering. There are only minor differences, and now we will find out which ones.

Tools and materials

When calculating the number of cork tiles required, it should be taken into account that most slabs are made in sizes 300 by 300 or 300 by 600 millimeters. The thickness of the tiles varies - 2 - 6 millimeters. Before finishing the walls with cork, you need to prepare the following tools: a plumb line, a level, an iron ruler, mounting scissors, a mounting knife, a notched trowel, a velor roller, a container for glue, a roller for processing seams.

Cork tiles are attached to the wall using glue. You can choose contact or acrylic adhesive for these purposes. The use of the latter composition implies one-sided gluing. However, it is still preferable to choose the first option, it will be of better quality.

Contact glue is more difficult to work with, since it requires double-sided gluing: it needs to cover not only the side of the cork board, but also the wall. Make sure that there are no bubbles and that the glue is applied evenly over the entire surface. After applying the glue, you need to wait a little until it sets.

Since cork material is made from natural raw materials, it can change its size depending on the microclimate in the room. Therefore, before you begin, you should unpack the cork tiles and allow them to acclimate and sit indoors for at least 24 hours at room temperature. This procedure will help avoid deformation of the tiles before they are installed on the wall.

Preparing the walls

Any base to which the plug can be attached is allowed (brick, concrete, plaster, wood). It is advisable to carry out work at an air humidity of about 35 - 65%; in extreme cases, you can always use a humidifier. The air temperature should not drop below 18 degrees in the room. Remember that the humidity of the walls in the room should not exceed 3%.

Before attaching cork tiles to the walls, you must carefully prepare the surface of the walls. If there is a need, then level them and cover them with a primer. To prime and level the wall, you should use only those compounds that are compatible with this type of finish. It is not recommended to use various putties, screeds and putties based on gypsum.

Then determine the center of the wall; for this it is customary to use a plumb line and level. Then draw two lines: vertical and horizontal; to draw them straight, you need to use a plumb line and a ruler. These lines must pass through the center point. As a result, it turns out that the wall is divided into two even parts horizontally and vertically.

Fastening tiles

Then take the first tile and place it at the intersection of the axes, outline it along the contour and apply a thin layer of glue to approximately 1 square meter. The tile is laid after applying the adhesive in such a way that its lower edge is located on the line of gluing to the wall. First you need to glue the bottom edge of the tile, and then press the entire rest of the surface so that no bubbles form under the tile and the tile sticks tightly.

When gluing tiles to walls, it is necessary to take into account the natural origin of cork. The structure of this material is such that it can break quite easily, so you should not lift the slabs by the corners, because they can break off and remain between your fingers. The material must be moved carefully, as shown in the video about decorating walls with cork.

Next, you need to completely glue the entire row, using the “running” technique, which is used for laying bricks. This method eliminates the appearance of uneven vertical lines, and they appear with the slightest change in the size of the tiles. Thus, it is customary to lay the second row with a shift relative to the first.

The edge of the first tile will be placed exactly in the center of the bottom tile, all this will be repeated for each next row. Don’t be afraid if the slab is not laid very level right away - you can move it along the surface of the walls until the adhesive composition hardens. Roll the joints using a special roller to avoid peeling off the corners.

Edge decoration

When finishing wall surfaces with cork tiles, the design of the edges is considered important. This is done by laying one slab on top of another, with which the surface is finished. To do this, you need to measure the distance from the walls and mark the place for gluing the edges. Then cut the tile along the marked lines with a cutting knife. If the edge design areas are narrow, then in this case it is worth applying glue to the tiles.

In the places where switches and sockets are located, to simplify your work, you need to use templates that need to be cut out and applied to the switch or socket. It is recommended to use thick paper for templates. After making the template, it is applied to the cork board and cut out, then glued in the designated area.

Cork tile care

Sometimes, despite your efforts, cracks and gaps remain between the sheets of cork. But this is also explained by the product’s ability to expand and contract. Don't worry, as this is quite easy to fix. Carefully insert and glue a thin strip of cork into the gap. Lift up the peeled edges and corners and coat with glue using a thin brush. Leave excess glue until completely dry, then remove with a knife.

To protect the cork coating from premature wear and increase its performance properties, it is customary to use special products. Since ancient times, coatings made from natural materials have been coated with oil and wax. A modern analogue of such substances is a special composition called oil-wax. Cork tiles treated with this composition do not absorb moisture and can be used in kitchens and bathrooms.

Another way to protect the surface of wall cork is to coat it with a special varnish: two-component polyurethane, water-based acrylic or ceramic. Remember that the use of parquet varnish is prohibited.

In addition, cork tiles, like other products made from natural materials, are susceptible to sunlight. Under the influence of ultraviolet rays, such slabs can change their color. To prevent such burnout of the cork, make sure there are curtains when finishing vertical surfaces.

Useful tips

A few more tips and notes that will help you install cork with glue efficiently and reliably:

- It is necessary to cover the cork sheet and the wall with latex-acrylic compounds.

- Acrylic adhesive is universal and can only be applied to the wall.

- When choosing the means that will be used to fasten the cork, take into account the weight of the canvas and the features of the wall surface.

- When purchasing glue, be sure to pay attention to the quality of the base and composition. Water-based materials are safe. Products that contain solvent can be toxic and flammable.

- Water-based adhesive materials are susceptible to high humidity in the room, as a result of which the cork coating may move away from the wall.

- Wear a respirator if you use solvent-based adhesive.

- Remove or turn off all sources of fire and heating devices that are located near the surface on which the plug will be mounted.

- Solvent adhesives have a short curing time of 10-30 minutes and set quickly. Immediately after applying the composition, press the cork firmly against the wall. Complete drying time does not exceed 12 hours.

- There are compositions of the so-called smooth polymerization, they allow you to adjust the position of the cork sheet during the installation process.

- It is extremely difficult to remove glue that gets onto the front side, so when working, you must be extremely careful, for example, use masking tape.

- Use a small spatula to scoop up a very thick mixture and apply it to the wall surface with a comb.

- A rubber roller presses tiles and wallpaper to the wall with maximum quality.

- If there are traces of hands left on the front surface, on the wax coating, you can remove them using a hair dryer. The wax will become softer under the influence of hot air, and the marks will disappear. If there is no wax coating, the contaminated area will have to be replaced.

- It is most convenient to glue rolled materials, since they are thinner, have natural colors and are coated with a special varnish.

Cork is an expensive material, but it combines safety, durability, excellent sound and heat insulation properties, and environmental friendliness. Cork panels on the wall look aesthetically pleasing and do not require replacement for a very long time.

The disadvantage of cork covering walls is that if you want to replace such wallpaper, it will not be easy to remove its remains from the surface. In addition, when chips and cracks appear, it is difficult to remove such defects.

However, if you follow the rules of installation and operation, the room will retain its luxurious appearance for a long time.

Today, cork backing is a fairly popular material for decorating various surfaces. Its heat and sound insulation qualities are beyond doubt. In addition, such material is unpretentious in operation. A cork canvas can replace the classic version of wallpaper, which will give the interior a certain charm. Let’s take a closer look at the installation features of this material.

Glue for wall plugs - which one is better?

What glue to use to glue cork to walls - types of compositions

Cork wallpaper, panels and other coverings made from this material began to be used quite recently, although the material itself has been used by mankind for many centuries.

If previously they were used only for the manufacture of floats, shoes or lids, now they are more often used by designers for arranging premises. Environmental friendliness, durability and beauty are the main advantages of the material, which increases its popularity year after year.

For fastening to wall surfaces, you need high-quality wall cork adhesive, as well as perfect knowledge of the technique of use.

Types and characteristics of cork materials

At the moment, construction stores sell various types of cork coverings for floors and walls. As for wall materials, they can be of two types - panels and wallpaper. The latter may have a paper base or be a cork roll.

The first ones will play the role of decoration, and the top will be covered with a wax or varnish composition. Due to their low weight, they can be glued not just to walls, but also to ceilings. Due to their small thickness, the effect of sound and thermal insulation should not be expected from them.

Some wallpapers should be applied with glue, while for others it is enough to tear off the inner backing and attach them like a self-adhesive film.

Rolled cork is also used as wallpaper, but costs much more. It is durable, thick and sold in rolls that will not be bent. This material is 100% natural, and is sometimes even sold untreated, and after gluing, additional decorative finishing is required. Most often, this canvas is used for pasting the hallway and kitchen.

Other materials for cork finishing:

- The panels are coated with varnish and wax on the top and are ideal for wet rooms.

- Plates - have a different shape, differ from panels (usually shorter and wider), and also serve as a material that insulates from cold and noise.

- Tiles - can be two-layer or single-layer. The second option is simple tiles made from one layer of cork. The first type of tile has a veneered top layer, and the bottom is brightly colored. Colored fragments in two-layer tiles are slightly translucent.

For the floor surface, a cork underlay is used, which is usually laid under laminate and parquet. They help reduce heat loss, reduce noise levels, and also help neutralize base defects. These substrates can also be glued to the surface of walls under any finishing material for room insulation, noise insulation, and improved adhesion of wallpaper to the surface.

Advantages of the material

Cork is a fairly expensive material that can serve for many years, and therefore the adhesive composition for it should also be selected according to the criteria of quality and performance without complaints. Most formulations operate at temperatures from +16 to +21 degrees and humidity up to 70%.

By the way, the compositions should have a short time before the initial setting, so that the cork panels do not need to be pressed for a long time. A high-quality adhesive composition must have the following properties:

- Resistant to moisture.

- High adhesion to cork and base material.

- Resistance to temperature changes.

- No negative reactions to contact with paint, wax, varnish, or other finishing materials.

The main types of compounds that may be suitable for gluing cork materials are described below.

Kinds

Acrylic compounds

If you don’t know what glue to use to glue cork to walls, then you should choose acrylic compounds. They are reliable, environmentally friendly, odorless, and also guarantee high quality adhesion of materials to each other, and professionals do not recommend using it for cork. Over time, the composition will destroy the surface of the cork coating and also impair its strength properties.

Water based solutions

The price of such adhesive compositions is quite high, because most of them will be manufactured abroad.

But the reliability will be at a high level, the consumption will be low, because the adhesive composition will be applied to the walls or cork material in thin layers.

As the liquid evaporates and polymerizes completely, the joint becomes much stronger. Water-based compositions have no aroma and are harmless because they are made from natural ingredients.

Mixtures with solvents

Such compositions are characterized by a higher level of adhesion, firmly glue wood, cork, and sometimes are even universal and are suitable for most building-type materials. They set almost immediately, and there is no need to wait a long time before gluing the panels to the walls.

Please note that the disadvantages of such adhesive compositions will be the unpleasant aroma that comes from the organic solvents introduced into the composition. Adhesives will be toxic (before they harden), and working with them will require strict adherence to safety precautions. Do not carry out work near fire sources - all solvents are flammable.

How to glue cork panels to walls - instructions

Using cork, you can finish the floor in the premises, while there is no need to remove the old covering in the form of linoleum or laminate.

tiled “floating” cork floors are made quite quickly, and when moving, they can be easily folded and taken with you.

When properly adhered, the coating will soften the sound of walking and falling things, and will also be able to withstand heavy pieces of furniture.

Interestingly, you can use cork to decorate the ceiling and walls, and the same wallpaper that you buy for wall repairs will be useful for the latter. You can cover the surface in the room fragmentarily or in a continuous manner, as your imagination dictates. Moreover, cork can be used to decorate pieces of furniture, for example, to replace damaged parts.

Preparation of material

Before installation, cork sheets or even rolls should be kept in the room for at least a day to help the material “adapt.” Among other things, the rolled cork is unwound and hung to stretch and take its working shape. The easiest way to cut is with a sharp construction knife that has replaceable blades. They then cut holes for sockets and switches.

Preparing the base

Before gluing cork wallpaper, the walls are thoroughly cleaned, dried and leveled. It is also worth removing moldy areas that could damage the previous coating.

Areas that are crumbling should be cleaned and then puttied, otherwise the cork will lie unevenly. Cork materials do not combine well with gypsum, and therefore this type of plaster should not be used.

Odorless cork glue for walls is ideal for the job.

Please note that the maximum height difference is determined by the floor; if it is large, you will need to first make a concrete screed.

At the end of the preparatory stage, the walls should be primed 1-2 times (there should also be no gypsum in the solution). For wood processing, primers with a fire protection function are additionally used.

The surface is dried to an acceptable level of humidity, and for this a heat gun or heater should be used.

Applying primer - what is it for?

Most people skip the priming step, although using cork will make future work much easier. The composition is partially absorbed into the upper layers of the base, strengthens the material and increases its strength.

After priming, adhesion to the glue will increase, and therefore the reliability of the adhesive seams will be significant. Moreover, when applying the primer, any remaining dust is removed, and the glue will apply evenly and will not roll off or form clumps.

If the base is complex and highly absorbent, then it is better to apply the primer twice.

Wall marking

Immediately before starting work, the walls are marked, especially if gluing is planned using a fragmentary method.

Before attaching the tiles, you will need to draw a grid, and when gluing walls with canvases, you can only apply signal lines.

If this is not done, there is a risk of product warping, which can be especially common when processing a large area. The easiest way to mark is using a laser level.

Gluing cork to walls

Usually they start finishing the floor, walls from a window or from a corner. In general, this will not play a big role; the master will be able to independently choose the area to begin repairs. Afterwards, all sockets and switches should be removed, and the technological type holes should be covered with pieces of cardboard, which are cut to the size of the holes.

Features of cork fastening

Cork tiles are installed according to the principle of brickwork - the second row and all the others are shifted ½ from each lower element. Wallpaper should be attached end to end, leaving no gaps or overlapping.

Fastening technology

The adhesive composition should be applied only to the cork or to both surfaces - the floor, walls and finishing material. The layer thickness should be followed according to the instructions, but it should not be more than 0.3 cm.

It is most convenient to apply the glue using a roller, a notched trowel or a comb (for very thick compounds). There is no need to immediately lubricate a large amount of material with the adhesive composition - the composition should not set until it is applied to the right place.

It is imperative to observe the time specified by the manufacturer for adjusting the plug position and record it until the end of such a period.

After applying the element or strip to the wall, it is carefully pressed, starting from the bottom edge. In the case of wallpaper, the edges should additionally be coated with adhesive using a brush. Then roll the cork with a rubber roller.

Once completed, you should wait until it dries perfectly, and then cover the seams and the material itself with a protective composition or varnish. This point cannot be neglected, since otherwise the material will serve less.

Formulations that contain wax are best suited.

If there is a solvent in the glue for cork on the walls, then the work can only be carried out in a respirator. Once the product gets on the front of the cork, it will be extremely difficult to remove it, and it is better to protect the edges of the elements in advance with masking tape.

The stuck drops are heated with a hairdryer and then blotted with a napkin. It is better to replace very dirty areas with new ones. Cork is an expensive material, and you should work with it carefully so as not to overpay and immediately get an excellent result.

The best brand of adhesives

Among the products that can be used to connect cork products, they are more often found by imported manufacturers. You can’t find them in all stores, and the range of such products is small.

"Traffic Moment"

This is a contact composition, which is special for joining different products made of cork, as well as for combined gluing of cork and other materials.

It holds finish well on metal and wood. The product will be resistant to frost, economical in cost and consumption, and the strength of the glue seam after drying.

“Moment Cork” is resistant to alkalis and weak acids.

The most popular areas of use of compounds:

- Laying floor and wall coverings, cork moldings, sheet and roll underlays.

- Bonding cork with rubber, leather, wood, various alloys and metals, felt and rigid PVC.

Please note that you cannot use an adhesive composition to join polyethylene, styrofoam, polypropylene, or plasticized polyvinyl chloride. The product will not contain toxins or harmful solvents. If it gets on different surfaces, wait until it dries, then roll it into a ball and put it away.

Material release forms

Reviews about using cork backing on the wall instead of wallpaper are mostly positive. As a material for wall decoration, you can take one of the produced forms:

- Cork sheets, which can be found up to 1 cm thick and 610-915 cm long.

- Sheets in rolls are quite voluminous, but the thinnest option, in which the length reaches 10-25 meters. The thickness of the cork is 0.2-0.4 cm.

- Cork panels. The release form is convenient for installation and is also convenient for transportation.

To use a cork backing on a wall under wallpaper, you should choose a material with a lower density, called cork agglomerate. Another type of this material is more dense and can be used as an independent finishing agent.

Features of cork finishing: advantages and disadvantages of the material

Cork finishing has many advantages:

- Cork is a natural material. Dust does not accumulate on it, it smells pleasant, is antistatic and reduces the level of various radiations.

- Wallpaper and tiles are very light.

- Cork is elastic and resilient. If you squeeze it, it will return to its original shape.

- It does not allow moisture and gases to pass through due to the presence of suberin. Suberin is a substance found in the bark of cork trees. Because of this, it does not rot or become moldy.

- The coating does not conduct heat and vibration well due to gas elements.

- The coating is very durable and wear-resistant.

- The material is hypoallergenic, does not harm health, does not absorb fat, oil and acetone.

- Does not allow sounds to pass through.

- It has thermal insulation properties and reduces heat loss. But even a very thick layer of cork cannot replace polystyrene foam of the same thickness.

- The cork is easy to install and easy to care for.

The main disadvantage of cork material is its expensive price.

Features of cork coating

Cork backing (it’s very easy to stick it on a wall instead of wallpaper) performs a number of useful functions:

- with its help you can smooth the walls without resorting to a lengthy leveling process using additional materials and mixtures;

- it has a high degree of sound insulation, which is extremely important for large areas or rooms with thin walls;

- the airiness of the material layers does not allow moisture to be retained, so condensation does not form when there is a difference in temperature or humidity;

- Cork can be used as a layer between the wall and wallpaper to increase adhesion.

Self-adhesive cork wallpaper

Self-adhesive cork wallpaper is an innovation in renovation. What’s so great about them is that they stick to the wall just like the more familiar self-adhesive film.

Imagine: the walls to be glued are smooth, clean, even. You have measured them and start cutting the sheets. Along the width of the wallpaper, you need to separate a three-centimeter protective layer. The open part of the wallpaper is glued to the wall, and the protective film is removed from the entire canvas, the sheet is glued completely.

The self-adhesive type of cork wallpaper has a particularly thin structure, making it more versatile: it can be used to cover walls, doors, decorate furniture, design panels, etc.

Advantages of using the material

Gluing cork backing to the wall instead of wallpaper provides a number of advantages:

- Durability. Cork does not become obsolete, and its service life can reach hundreds of years.

- The cork covering can be dismantled countless times, while it will maintain its integrity and characteristics.

- Wear resistance. Due to the elasticity of the material, low-intensity mechanical impacts on the surface go unnoticed.

- Resistant to temperature changes. When heated or cooled, the cork structure retains its original appearance and strength.

- Cork perfectly hides defects in the structure of walls.

- Both the technical type of the material and the agglomerate do not allow current to pass through; in addition, they are not capable of accumulating static electricity.

- The inability to accumulate microorganisms and fungal spores inside its structure determines the antiseptic properties of the material. And suberin, which is used to treat cork, acts as an antiseptic.

- Thanks to sanitary treatment at the production stage, the cork substrate (it is often glued to the wall instead of wallpaper) is unattractive to small rodents and tree pests.

- No aggressive chemical compounds are used in the production of the material, and therefore it can be considered hypoallergenic and environmentally friendly.

- In case of possible exposure to fire, the cork surface does not ignite, but can only smolder, and there are no toxic emissions.

- Cork wallpaper effectively absorbs noise and retains heat.

The process of covering walls with cork

Glue is applied to the prepared material

Now the moment has come when you move specifically to work. The development is simple, but you need to work from the window opening. It is worth noting that it will not be so easy to carry out such work without outside help; even ordinary wallpaper is difficult to glue on your own, so use the help of your wife, another relative or friend to glue the wallpaper together: one of you needs to hold the cut panel near the ceiling, and another - to equal him.

The quality of work can depend on many factors. The main one is the error-free application of glue. To be sure, it can be applied not only to the panel, but also to the surface of the wall. However, few adhesives are recommended to be applied in 2 layers. Therefore, it is better to look at the information contained on the packaging in the instructions for the glue, and also for the cork coating.

Once you have applied the adhesive composition to the surface, you need to wait 20 minutes for it to absorb. This promotes a stronger grip. The main thing is that the adhesive layer is not the thinnest, since such wallpaper may fall off over some time. To ensure proper fixation, the panel with the applied glue must be pressed tightly to the wall surface. It is convenient to use a roller.

Gluing the cork

Now look at certain requirements that must be adhered to in order to properly glue cork wallpaper:

- They only need to be glued end to end.

- During work, do not bend the material to the point of breaking, as the veneer will easily crack.

- Much attention must be paid to the corners; they must be trimmed and connected in the corner itself.

- If there is waste, it can be used in places that are difficult for the eye to see.

- Everything unnecessary must be cut off not with a knife, but only with scissors.

So, the first panel needs to be glued, looking at the markings. Let your assistant hold it while you slowly glue the strip to the surface of the wall. Once everything is done, apply glue to the next panel, and while it is standing, go over the glued piece with a roller. Glue all further strips end-to-end, using a rag to remove any remaining glue that comes out while working with the roller. Cut off all excess pieces. Once the room is fully prepared, leave it for 3-4 days so that the finishing material is completely dry. Then, if desired, such wallpaper is opened with a “breathable” varnish. This can help increase the operating time of the coating and protect it from damage.

The same should be done with all rooms in the home if you want to treat them with cork. Now you know how to glue

Roll wallpaper made of cork. But, these are still a few!

Necessary tools for installing plugs on walls

Is it possible to glue cork backing to walls without using specific equipment? For installation you will need quite simple tools:

- pencil or marker for marking;

- durable ruler, more than 1.5 meters long;

- roulette;

- fine-toothed spatula;

- sharp stationery or construction knife;

- ordinary solvent;

- masking tape;

- glue;

- gloves to protect your hands and a rag to remove excess adhesive.

How to glue cork to walls - instructions from preparation to finish, photos and videos

When choosing finishing materials, one of the criteria for the appropriateness of their use in a particular room is hygroscopicity, that is, the intensity of moisture absorption.

The lower this indicator, the less often you will have to think about the next repair. From this point of view, cork coverings are one of the best options. Before considering the technology of gluing walls, you should clarify which materials are best to work with. After all, the concept of “cork” is a generalized name for a product. There are several options for such a coating, and not every product can be applied independently.

How to choose the right adhesive for attaching a cork to a wall is described in detail here.

- Brief description of types of cork materials

- Wallpaper

- Tile

- Procedure for working with a stopper

- Preparation of material

- Preparing the base

- Application of primer

- Wall marking

- Gluing cork to the wall

- Mounting feature

- Fastening technology

- Useful tips

How to glue cork backing?

The gluing process is similar to wallpapering. If the cork is purchased in a roll, convenient sections should be separated from it for alternate gluing. The optimal size for manipulation is a sheet of 1 by 1.5 meters. If the material is presented in the form of panels or slabs, it is even easier to install it.

The photo above clearly demonstrates how to glue cork backing to a wall instead of wallpaper.

Important! Before gluing a cork rolled into a roll, it should first be leveled. To do this, you need to unfold the material on a hard surface and put pressure on top. After a day, the cork will be ready for cutting.

To draw straight marking lines, it is convenient to use a metal ruler or a large square. Cut the canvas with a knife.

The steps for attaching the plug to the wall are as follows:

- Apply homogeneous adhesive to the wall with a notched trowel. The layer should be thin (no more than 1.5 mm).

- Cover the edges of adjacent surfaces with masking tape to avoid staining.

- Glue the cork sheets, starting from the top corner on one side.

- Using a rag, you should immediately remove excess glue at the joints of the material.

- After gluing large sheets of cork, fill the remaining wall space with small pieces.

For better adjoining of the borders of the canvases, especially at the corners, they can be fixed with masking tape until the entire wall dries.

After covering the entire wall or planned area, remove the masking tape.

The final stage is applying varnish to the cork surface. Typically no more than two coatings are needed.

Stages of installing cork walls

Before the covering can be glued, you need to carefully prepare the walls and choose the most suitable adhesive for the cork covering.

Glue selection

Which glue is better to choose depends on many indicators:

- toxicity level;

- setting time;

- reliability and strength.

Not every glue has only positive characteristics, but you still have to make a choice. Therefore, you can see how to glue the cork covering below:

- "Moment". You can glue a cork to a wall using this glue. The glue is universal, durable. Point or linear application is very convenient, especially if tiles are being glued. But there are disadvantages: it can destroy the cork layer or deform it. In addition, Moment is a rather expensive and toxic option. Therefore, if you choose “Moment” glue for cork, then it is better to take a special option - “Moment Cork”.

- "Traffic Moment." An excellent alternative to the usual “Moment”, it is non-toxic, water- and frost-resistant (can be used when covering a glazed balcony), and does not contain toxic solvents.

- "Decol Vern." It is used specifically for cork coverings, a very reliable option. But: highly toxic (you need to work in a respirator), its chemically active composition obliges you to avoid getting the glue on your skin. Flammable. Like Moment, Decol Vern glue sets quickly, so application to the wall must be precise the first time. For the same reason, it is not suitable for wallpaper.

- "PVA". Anyone who has glued cork to PVA knows that this option is not for wallpaper: the glue simply will not withstand their weight. Suitable for tiles, but with the risk of deformation of the cork coating due to the water-based adhesive.

- "Wacol", "Cork House". Great options if you need an odorless glue for cork. Also, these options do not contain solvents, are environmentally friendly, moisture-resistant, and quick-drying.

- Acrylic glue for cork. Used for one-sided gluing, when only the coating is applied.

If a suitable option is not found here, you can consult the construction department on what to glue the cork covering to. In the case of using the substrate as an intermediate layer, it is important to know how to glue the cork to the cork: any suitable glue is used here, but the surface of the substrate must be rough (without varnish).

Preparing the walls

Before pasting, the walls must be cleaned, dry, and leveled. It is also necessary to remove possible mold, damaged previous coating, and fill up crumbling areas. Don't ignore the need for primer.

It is better not to neglect these rules, otherwise the cork on the walls will lie unevenly, and in some places it may come off.

If fragmentary gluing is to be done, you need to mark it on the walls, and also draw a diagram for gluing the tiles.

Since cork is incompatible with gypsum, it is not recommended to cover or putty walls with primers or screeds containing it.

Gluing the coating

When everything is ready, you can proceed directly to pasting. To know how to glue cork to a wall, you need to follow the following rules:

- if the coating is unprotected, be sure to cover it with varnish or wax;

- you can spread either only the cork, or also the wall, and choose the thickness of the adhesive layer according to the instructions;

- after spreading the glue, wait from 15 to 30 minutes (depending on how the glue sets) and apply the material to the wall;

- if you are gluing a tile, start fixing it from the bottom cut, gradually moving upward;

- After gluing, roll the cork with a rubber roller to remove possible air bubbles and irregularities, especially at the joints and corners;

Gluing the cork must be done at a temperature not lower than 18 degrees!

Something in the interior periodically needs to be changed, and sometimes in such cases the question arises: is it possible to glue wallpaper to cork? Yes, but it is better to do this over technical cork, which has a rough surface, or use acrylic primer for a regular coating, and then putty it.

Before pasting, the coating must “get used” to the temperature of the room; to do this, unrolled, it is left to lie in the room where the repair is planned for 24 hours.

It is unlikely that cork coverings will lose their popularity, because their environmental friendliness, versatility, beauty and ease of use are what the modern consumer needs.

Cork backing for walls: reviews from those who took the risk

An increasing number of people who undertake renovations prefer natural materials. This explains the growing popularity of cork as a wall decoration.

Many repairmen who have already had experience gluing cork to walls note its advantages such as environmental friendliness, naturalness, ease of installation and operation. Cork panels also attract with their exoticism, because with their help you can create an original interior that looks expensive and stylish at low cost. Users also note the excellent sound insulation of the material, which is extremely important in modern apartment buildings.

The disadvantages include the need to purchase a special adhesive composition, as well as the specific smell of the material, which, however, disappears in a short period of time. In addition, users note that a cork wall should definitely be covered with a protective layer of varnish, since a cork wall is prone to crumble.

Thus, cork backing is perfect as a material for wall decoration for practical owners, as well as for those who like to surround themselves with natural materials. This design option can bring special comfort to the interior of the room by adding woody notes to it.

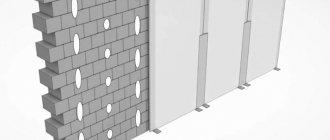

Composition and characteristics of Vikanders cork panels

The structure of a cork wall panel is shown in the diagram.

1 - acrylic or ceramic varnish, or oil-wax is used to protect the coating.

2 - natural cork veneer sets the unique decor of the coating.

3 - base layer of agglomerated cork.

The Vikanders wall plug has dimensions of 600x300x3 mm or 900x300x3 mm. Installation is carried out using a special adhesive for cork coverings - water-based or solvent-based.

Popular brands of cork wallpaper

There are several brands that get the best reviews. One of these is Ibercork. Typically, such wallpapers have light colors - beige, yellow and their shades.

Cork wall coverings from the best manufacturers can be found in the Leroy Merlin network of construction hypermarkets.

Sometimes such wallpaper is coated with colored or neutral varnish

Wallpaper from traffic jam in Leroy Merlin:

- They are sold both in the form of cork tiles and in the form of rolls.

- Cork tiles typically weigh 3.3 kg. But only the heavy weight can be considered a drawback; the performance characteristics of the tiles are excellent.

- Cork rolls in Leroy Merlin are not electrified, which means they are not afraid of dust, bacteria or microbes.

Leroy offers many colors and shades from leading manufacturers on the world market, which, of course, makes this coating more attractive to choose from.

Operation of cork finishing

Cork coverings are prone to contraction/expansion under the influence of room temperature. This feature should be taken into account not only during installation, but also during operation. Ideal conditions for cork coverings: ► Relative air humidity - up to 65%. ► The general temperature in the room is about 20 degrees. Cork has one more feature - it fades when exposed to direct sunlight. In order to preserve the original appearance of the material for as long as possible, it must be protected from the sun using curtains, curtains, etc.

Roll stopper

Rolled cork can be technical (used for sound insulation and wall insulation) and decorative (in this case it consists of two layers - a substrate and a decorative top layer). The material is obtained by hot pressing of cork chips. Due to the high percentage of natural glue in wood - suberin - a continuous monolithic material is obtained without the addition of chemical components. The standard roll length is 10 (less often meters, width is 50 cm, but quite often you can find rolls 1 m wide.

The material is obtained by hot pressing of cork chips. Due to the high percentage of natural glue in wood - suberin - a continuous monolithic material is obtained without the addition of chemical components. The standard roll length is 10 (less often meters, width is 50 cm, but quite often you can find rolls 1 m wide.

The process of installing rolled cork is in many ways similar to gluing cork wallpaper. But due to the fact that the material is more fragile, it is much more difficult to securely and accurately fix it on the wall. Therefore, it is better to entrust the installation of a roll plug on the wall to professionals. Cork in rolls usually does not have a protective layer, so after installation it must be treated with wax or varnished.

Photo: wall cork panels for interior decoration

Choose cork flooring and wall panels in the online store and order professional installation of cork in Moscow and Odintsovo!