Lining differs from ordinary edged boards in the presence of longitudinal grooves. They provide a tight connection between the elements. The surface after finishing is smooth, without gaps and neat in appearance.

This is why lining a bathhouse with clapboard is becoming so popular. Wood material allows you to create a microclimate favorable for relaxation in the room. The installation process is simple and easy to learn on your own.

Users often search for:

- Bath shelves

- DIY bath floor

What type of wood to choose for finishing a bath

Regular and eurolining are available for sale. The first one has a rough surface, the second one is completely smooth.

Finishers recommend using eurolining for bath lining, since the raw material has holes for ventilation, which prevents condensation from accumulating inside the material. It is made from premium quality wood and lasts many times longer.

Among the advantages of using eurolining in a bathhouse:

- Large and convenient dimensions of the groove and ridge (length can reach 8 mm).

- The presence of compensation slots ensures good ventilation of the planks and prevents the formation of cracks on the surface.

- The raw materials are already covered with a protective layer of antiseptics, which are used in rooms with high humidity and do not contain toxic substances.

The correct type of wood is also important. The list of recommended species is different for interior and exterior decoration.

Inside (dressing room, steam room)

For a steam room, it is permissible to use only hardwood with increased resistance to moisture. There should be no knots or other defects on the surface. Grade - first or highest.

You can line the steam room with clapboard from:

- aspen;

- linden;

- alders;

- oak;

- Abasha.

Coniferous species in the steam room can be used cedar, larch, hemlock. When heated, they do not release resin.

It is better to use inexpensive pine for lining the dressing room. It is not used in a steam room due to the release of resin, which sticks to clothes, and when heated, it can cause a burn.

Let's look at the properties of wood species that are suitable for finishing baths.

Alder

Hygroscopic. It has low thermal conductivity. Has a pleasant aroma. Has a beneficial effect on health.

Often used to decorate the interiors of country houses and closed gazebos. The downside is the high price. Sold in pieces up to 3 meters long.

Oak

Expensive raw materials, which is why it is not so popular. Difficult to sand or trim. But rot does not form on it. Durable. Oak lining does not require additional processing before installation.

Aspen

Color – white with a silver tint. Tree rings are visible on the surface. Light in weight. Tolerates temperature changes and high humidity well. Thermal conductivity is low. The raw material is soft. Convenient to process.

Over time, aspen lining becomes even stronger.

For periodic maintenance, when the color of the surface becomes dull, it is enough to sand it.

Linden

Many dacha owners prefer to decorate their bathhouses with linden clapboards. This is due to its beneficial properties, beautiful appearance of the material and ease of processing.

Found in light colors with a brownish or reddish tint. It has a matte shine and low thermal conductivity.

When used in a steam room, it releases beneficial microparticles. At the same time, the wood is durable and does not dry out over time.

The only caveat is that contact with iron leads to its oxidation and the formation of rust.

Abashi

This is the name of African oak. Its height in the natural environment is up to 40 m, width – 3 m.

In section, the color of the array is light yellow, cream. Abash has low thermal conductivity. The raw materials are durable. The structure is dense. Does not deform under the influence of external factors. Easy to process.

It will take a lot of money to sheathe the inside of a Russian bathhouse with abash, but such a coating will last for decades without requiring additional processing or maintenance.

Lining is not available for sale in every hardware store.

The same situation applies to ash lining - it is rare and the price is high.

Disadvantages of hardwood upholstery - the color fades over time, you have to periodically coat the surface with an antiseptic.

Coniferous raw materials are rarely used in the steam room. Since most of them, when heated, release resin. But these rocks are great for finishing walls, ceilings in washrooms and dressing rooms.

Conifers are inexpensive, easy to process, and have a pleasant pine aroma.

Let's look at the properties of the most popular of them.

Cedar

It comes in a variety of colors due to its wide range of growing locations. Available in beige to coffee shades. Durable. Resistant to differences in temperature and humidity. Requires mandatory treatment with antiseptics. The price is high.

The disadvantage of cedar lining is that it can begin to release resin after several years of use, without even heating up.

Larch

Demanded coniferous species.

Many builders line the steam room with hardwood clapboard. It can be used to cover the ceiling, walls, and in the shower, locker room, and rest room.

Does not release resin. Durable. Withstands temperature changes. Doesn't rot. Not susceptible to damage by insects.

When exposed to moisture it only becomes stronger. The structure of the wood is homogeneous. The fumes from larch have antiseptic properties.

Pine

Used for finishing work in the dressing room, locker room, and rest room. The surface of the lining is smooth. It comes in beige, brown colors with a slightly reddish tint. The structure of the growth rings is clearly defined. Resin channels are noticeable. Excellent resistance to mechanical stress. Convenient to process.

Pine is not used for lining the steam room. But if the owners do not have another lining at their disposal, then before using the steam room they will have to heat it several times to remove any escaping resin.

You only need to purchase top-class lining.

Hemlock

Coniferous species from the pine family. The tree is also called Canadian hemlock. Unlike pine, it is very durable and is not afraid of high humidity or sudden temperature changes. Therefore, hemlock clapboard is used to cover the shelves, ceiling, and walls in the steam room.

Does not rot or deform. Thermal conductivity is low. When heated, it releases essential oils that are beneficial to health.

Despite the advantages of coniferous trees, most owners prefer deciduous linden or aspen. A pleasant aroma, low thermal conductivity, and ease of processing make them popular in the decoration of baths and other premises.

Outside

For cladding the outer part of the structure, moisture-resistant larch, sometimes oak, abashi, and premium pine are purchased.

The most popular type of profile is the block house, which imitates a rounded log. In this case, the tongue-and-groove connection is preserved. The front side is round, the inner side is flat or with ventilation ducts.

Among the nuances of external fasteners:

- Openings for windows and doors are decorated with a profile (beam).

- Only the highest grade lining is used, without knots or other defects.

- Two posts are fixed at each corner.

- The fastening method is through.

- The parts are mounted with the groove down to prevent precipitation from getting inside.

An alternative to wood lining is plastic. It is resistant to any weather conditions and has a wide selection of colors, including wood imitation. The downside is that the plastic is fragile, so installation is carried out carefully, otherwise the planks may crack.

Ways to fasten the lining

Two types of fasteners are used for installation.

Kleimers

Safe type of installation. Doesn't damage the planks.

A clamp is a mounting bracket with 2-3 holes for self-tapping screws (nails or a construction stapler), which is placed on the lining tenon.

Having fixed the bracket on the tenon, it is attached to the sheathing beam. You need to start from the center, then move to the edges, maintaining verticality or horizontality. Claypers are used for laying lining on ceilings and walls. If necessary, it will be possible to dismantle several planks without damaging other elements of the bathhouse design.

Nails or screws

For the self-tapping screws, pre-drill a hole with a diameter slightly smaller than the size. Self-tapping screws are screwed into a tenon or groove at an angle of 45 degrees.

The nails are simply driven into the slats in the right places. To avoid rust on the surface, it is recommended to use copper or galvanized nails. But it is worth considering that they will cost twice as much as usual.

In any case, the cap will be flush with the bar. Places of fasteners are sanded and polished. There should be no burrs or defects left on the surface.

The disadvantage of through-mounting the slats is that the metal elements will gradually begin to rust, streaks will appear, or there is a risk of getting burned when heated.

Headlining

The decoration in the bathhouse will be disharmonious if the walls and ceiling are covered with materials that are identical in appearance but of different quality. This method is used only for the sake of economy. A high ceiling can hide differences in color shade or other surface features. But the bathhouse is traditionally built with a height of no more than 280 cm.

In order for the design of the room to correspond to the mood evoked by hygiene and relaxation procedures, environmentally friendly and aesthetically attractive materials are used in the cladding. If the walls are covered with wooden slats, most often the ceiling is made in the same way. The installation rules are the same. A sheathing is also built on the ceiling, having previously drawn up a drawing of it. The lamellas are attached to the bars using the same method as for wall cladding.

How to install lining in a bathhouse

This can be done in two ways - vertically or horizontally. Let's look at each of the options.

Vertical

This method is often used by construction teams who finish a turnkey bathhouse. The planks are selected according to height and fixed without trimming. This makes it convenient to design corners. Installation does not take much time and is cheaper than horizontal. Accumulated condensate will easily flow down the slats.

The vertical arrangement of the lining allows for better heat accumulation inside the room.

The disadvantage of vertical fastening is that if at least one of the planks is damaged, the entire wall will have to be dismantled.

But there is no natural air circulation between the sheathing and the wall, so the likelihood of fungus formation increases.

Over time, the joints become noticeable as the boards dry out.

This is how it is better to finish saunas where the air is dry and there is no high humidity.

Horizontally

Fixing the slats across has a number of advantages:

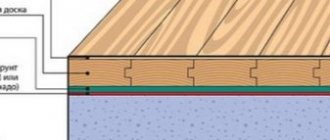

- The lining is mounted with the tenon facing up. Due to this, condensation does not accumulate under the casing, and there is no risk of fungus formation.

- Under the horizontal lamellas, the sheathing is attached vertically. There is full air ventilation between the sheathing and the wall.

- The boards are easy to replace without harming the entire finish. The floor in the steam room is always wet, so the lower planks quickly become unusable. It is not difficult to carefully remove and replace them with new ones. And with vertical installation, you will have to cut off the entire bottom of the planks at the same level or even dismantle the entire wall.

- Suitable for lining a bathhouse made of fresh logs. Shrinkage will occur over several years, so the height of the walls changes. It is easy to replace horizontally the planks located at the top and bottom of the walls with new ones.

This method of installing lining will be correct when finishing a Russian bath, where high humidity always remains.

Recommendations for choosing the direction of fastening the lining

The finishing panels can be fastened vertically or horizontally

The finishing panels can be fastened vertically or horizontally. You can find basic information about each method in the following table. The data obtained will help you make the right choice.

Table. Options for fixing the lining

| Finishing direction | Illustration | Basic information |

| Vertical | Vertical fastening of the lining | Vertical fastening of panels has a big drawback - the boards heat up unevenly along their length, which negatively affects their service life. Vertical cladding is optimally suited for steam rooms operated primarily in conditions of high temperature and low air humidity, i.e. in sauna mode. To ensure more efficient air circulation in the space between the insulation and the lining, several holes are usually drilled in the sheathing. |

| Horizontal | Horizontal | In the case of a horizontal arrangement, temperature deformations of the lining material will be much less noticeable. Horizontally oriented finishing allows you to visually expand a small steam room. When the panels are fastened horizontally behind them, more efficient air circulation will be ensured - in this situation, the sheathing will be attached to a vertically oriented frame, as a result of which the gap will also be vertical. In addition, with this orientation of the frame it will be much more difficult for rodents to get into the space behind the skin. Horizontal lining is attached much faster and easier than vertical lining. Important! If you decide to orient the trim panels horizontally, make sure that the groove “looks” down. |

Thus, the optimal direction of the casing elements is determined by the operating features of the steam room. If this is a real Russian bathhouse with splashes and steam, it is better to mount the boards horizontally. In saunas, the option of vertical orientation of the cladding elements demonstrates itself well.

What is the purpose of foil?

To achieve effective energy saving in a bathhouse, you will need to not only insulate it, but also use reflective material in the form of a special foil film. Masters claim that it helps return up to 95% of the heat into the room.

The result is that fuel for the stove is saved and the duration of the fire is reduced.

For baths, aluminum foil with a thickness of 30–300 microns is used. It is used in combination with other insulation or is already fixed as its top layer.

Therefore, before covering, they first attach insulating material to the walls and ceiling, thanks to which the heat does not escape beyond the bathhouse. An insulated steam room heats up faster and retains heat longer.

The following are the advantages of foil:

- It acts as a vapor barrier and blocks the access of moisture to the insulation. The generated steam remains on the walls of the steam room.

- Its service life exceeds 50 years. Wooden elements will begin to rot faster than the foil layer will deteriorate.

- Excellent sound insulation. Foil can absorb up to 70% of all sounds and noise.

- Fireproof raw materials. Does not burn. It will become an obstacle to the spread of fire.

- Bathrooms warm up faster and take longer to cool down.

- If you fix the insulation with a foil layer, then the foil will prevent it from falling off.

Among the disadvantages, the following should be noted:

- When there is a difference in temperature outside and indoors, condensation appears on the surface of the material.

- It is important to leave a gap for ventilation before covering. If this is not done, the resulting condensate will begin to be absorbed into the sheathing, which will lead to rotting of the lining.

- Foil has poor throughput. As users say, she is not breathing. Therefore, the rooms must have good ventilation, both forced and natural (windows, doors).

- Aluminum particles accumulate in the lungs, causing various respiratory diseases. But if you use the sauna periodically, the risk of harm to health is minimal.

To achieve the maximum effect from using foil, it is important to follow the tips for installing thermal insulation step by step.

Covering saunas and baths: what's the difference?

Bathhouses and saunas differ in humidity and temperature.

In the sauna, the air is dry with humidity up to 8% with a permissible temperature range of 80–140 degrees.

In the Russian steam room, high humidity is always maintained with an indicator of up to 70%. In this case, the maximum permissible temperature is up to 100 degrees.

This difference is due to the fact that moist air has greater thermal conductivity than dry air. Therefore, in a Russian steam room, the human body heats up faster and it is easier to breathe in it.

There are no restrictions on the choice of tree species for sauna cladding, with the exception of pine. Raw materials are less susceptible to moisture and therefore last longer. Installation method: vertical, horizontal.

For lining a Russian bathhouse, it is better to take lining made of alder, linden, abasha, and larch. The combination of several breeds at the same time looks beautiful. The installation method is predominantly horizontal.

Features of lining installation depending on the bathhouse material

Brick or foam concrete baths must be insulated from the inside without fail. The exception is the use of a bathhouse only in the warm season.

Mineral and synthetic raw materials are used as insulation in the form of individual slabs or in rolls (mineral wool, expanded polystyrene).

The floor will also have to be insulated. It will be cheaper and more reliable to use expanded clay backfill.

An excellent option for heat insulators for walls and ceilings are those covered with a layer of foil. Izover, Ecoteplin (protected with foil on both sides), Thermostop, Ursa are suitable.

A brief procedure for finishing a bathhouse made of bricks or foam blocks:

- On the ceiling and walls we make lathing from wooden slats of average thickness 5-10 cm (the exact figure depends on the thickness of the insulation).

- We place insulation in the recesses of the sheathing. To prevent it from falling out, we fix it with temporary strips. If desired, fix the glassine on top.

- If the heat insulator is covered with a foil layer, then this item can be omitted. If the foil is attached separately, this should be done with an overlap of 20-25 cm, so that the overlap from the ceiling extends onto the walls, and from the walls onto the floor.

- To obtain an airtight coating, we go through all joints with metallized tape.

- We nail slats on top with a thickness of 2-4 cm, on the ceiling the thickness increases to 5 cm.

- We leave gaps for ventilation and fasten the lining.

If the exterior finishing is carried out in a brick bathhouse, if sand-lime brick was used, then for a structure made of foam blocks, exterior cladding is required. This is due to the porous structure of foam concrete. If it is constantly exposed to moisture without protection, it will begin to crumble. It would not be superfluous to insulate the outside of the room with expanded polystyrene.

In bathhouses made from fresh logs, it is possible to simply attach foil without using additional insulation, put the sheathing on top and install the lining.

In frame baths made of boards and timber, the finishing and insulation of walls occurs according to the same scheme as in brick structures.

It is important not to forget to treat the material with antiseptic solutions or impregnations after finishing.

Preparatory work for wall cladding

Before quickly sheathing the inside of the bathhouse with aluminum foil and wooden clapboard, it is necessary to insulate the walls. Before laying the insulation, install the counter-lattice and sheathing. A layer of vapor barrier is laid on top of the insulation.

Thermal insulation device

The best material for insulating baths is basalt wool. This material has good thermal insulation and a high degree of fire resistance. Basalt wool does not rot. This type of insulation does not burn and does not emit harmful substances. Basalt can withstand temperatures up to 1500° C.

Experts recommend using Rockwool brand “Light Butts” mineral wool. The mineral wool of this company is of high quality, increased density and affordable price.

To cut basalt wool sheets, large, sharp knives with a high-quality blade are used. When cutting, the knife blade is held at an angle of 30-45° to the surface of the blade. When tilted, the blades dull much more slowly.

The width of the canvas is taken to be 2 cm greater than the distance between the vertical posts of the sheathing. The increased width helps to fix the blades in a constant position.

Thermal insulation sheets are laid in 3 layers with overlapping joints. The amount of overlap is equal to half the length of the canvas.

All layers are laid in height within one span of the sheathing. The laying direction is from floor to ceiling. They move to another span after laying all the layers of the previous span.

Attention! You should not choose insulation from artificial and synthetic materials. When exposed to high temperatures, they release substances harmful to health.

Laying the first layer begins from the floor. First, the whole canvas is laid. After laying all the canvases of the first layer, the second layer is laid.

Laying the second layer also begins from the bottom. For overlapping joints, the length of the first web of the second layer is taken equal to half the length of the standard web.

At intersections with obstacles, elements of the required shapes and sizes are cut out.

Before covering the bathhouse with clapboard, care should be taken to protect the walls from dampness and rotting. Therefore, after installing thermal insulation, they begin to install the vapor barrier material.

Vapor barrier device

The vapor barrier layer is designed to protect walls from condensation and increase the heat-reflecting properties of the insulation.

The work of laying vapor barriers is the most critical when constructing bathhouses. The efficiency of steam use depends on the quality of vapor barrier work.

Aluminum foil with a thickness of 50-80 microns is used as a vapor barrier. Attaching the foil begins from the corner of the room in the direction from bottom to top.

Advice. Finnish foil is in greatest demand. The products of this company have high quality, durability and increased heat-reflecting properties.

Vapor barrier sheets are sewn with metal nails or staples to the vertical posts of insulation cells. To attach the foil, use a pneumatic gun or a special construction stapler.

The foil is laid with an overlap of 2-3 cm of vertical seams. All seams are taped with aluminum adhesive tape.

Advice. To seal the seams of the foil, use Unibob adhesive tape, 50 microns thick. This tape adheres well, has high strength and durability.

In places of transition from the walls to the floor and ceiling, the foil is laid with an overlap of 5-10 cm in each direction. The free ends are sewn to the ceiling and floor with nails or tacks.

At the junctions of walls and ceilings, gaps often appear in the foil. To eliminate these gaps, use foil corners. To make such a corner, a piece of foil is placed on the corner of a table or chair. The resulting shape is carefully beaten with a light object to soften the foil. The broken corners are glued with aluminum adhesive tape. The manufactured corner is inserted into the corner and carefully taped.

Advice. To prevent damage to the foil, it is necessary to cut the edges of the bars at 45 degrees using a plane.

After completing the work, check the quality of the vapor barrier installation. Any damage found is covered with adhesive tape.

After installing the vapor barrier, the installation of the counter-lattice begins.

Counter-lattice device

The counter-lattice serves as the basis for the main sheathing. Designed to ensure air exchange in the space between the foil layer and the lining.

To construct the counter-lattice, wooden blocks with a cross-section of 20x20 mm are used. The bars are nailed to the vertical posts of the insulation cells. The distance between the slats is taken to be 400-500 mm. Installation of counter-lattice slats is carried out according to level and plumb.

Advice. Do not use cheap knives with low quality blades to cut basalt wool. Such knives cannot withstand high mechanical loads, quickly become dull and fail.

When installing a counter-lattice, a hole with a diameter of 80-100 mm is drilled in the ceiling for the exhaust duct pipe. A sealing cap (valve) is inserted into the hole. During bath procedures, the hole is closed. To ventilate the bath after washing procedures, the hole is opened.

Periodic ventilation prevents the appearance of dampness and rotting of the lining. To ensure air exchange, a gap of at least 2 cm is provided between the lower end of the lining and the floor.

Treatment of lining with protective agents

Sheathed walls are subjected to protective treatment.

Solutions that are water-based or contain wax are considered the safest to use. They are environmentally friendly and harmless to health. A waterproof film is formed on the surface of the lining, which prevents moisture from penetrating into the wood, extending its service life.

Before application, it is important to read the manufacturer's instructions. Often applying the product even in one layer is enough.

Using wooden paneling to cover the bathhouse, the owners create a special microclimate inside the room, which has a positive effect on the health of vacationers. Plus, wood is a natural material that fits perfectly into the interior decoration of the bathhouse, looks beautiful and smells nice.

How and what is the best way to decorate a bathhouse inside

Arranging a bathhouse is not an easy task. In this building there are always several rooms, each of which performs its own function. Those materials that are optimal for a dressing room and rest room are not always suitable for finishing a steam room or washing room. Therefore, the owner of a bathhouse needs to know what the criteria for choosing the design and cladding of each room are.

The interior decoration of the bath can be made of the following materials:

- lining;

- planed boards;

- salt panels;

- brick;

- porcelain stoneware;

- natural and artificial stone;

- plastic panels;

- moisture-resistant gypsum plasterboard and gypsum fiber board;

- ceramic tile.

Listed are materials that can be safely used for cladding walls and ceilings of any room. The environmental friendliness and durability of these products have been tested by many years of practice. With the right choice of materials, finishing a bathhouse can be complicated by only one thing: not knowing how to lay, stick or mount them correctly.