Paints

Large boats are painted with two types of paints: above the waterline - one, below the waterline - another. But as a rule, an aluminum boat is painted with one paint, since the size of the boat is small, it is not a boat.

Oil paints

These are paints and varnishes based on drying oils.

All oil paints and enamels contain pigments that give them color.

An aluminum boat can only be painted with paints that do not contain lead as a pigment. Lead-based oil paints will destroy aluminum. Any other pigment in the paint will not harm the boat.

It is better to choose enamel rather than paint for painting a boat; it is more durable and glossy.

Oil paints are applied only after priming.

Epoxy paints

In recent years, an increasing number of people who decide to paint an aluminum boat or boat prefer paints based on epoxy resin.

Epoxy paints should not be applied to boats that have previously been painted with oil paints.

Epoxy paint is applied in a single layer. Coloring is done in small areas. Epoxy paint is toxic and requires caution when working with it.

Interspeed 340 or Temacoat RM finish paints fall into this category. 40.

Alkyd paints

Created on the basis of alkyd resin, the solvent is white spirit. They are less durable than acrylic ones, the boat will have to be renewed more often, perhaps annually, but the color turns out to be richer and more beautiful, and the color palette is richer.

For example, for an aluminum boat, alkyd enamel XB-124 is suitable, applied to primers FL-03K, VL-02, VL-023.

Acrylic paints

These are water-dispersed paints and varnishes on a polyacrylic base.

They are considered the most durable and inexpensive, they last a long time and do not turn yellow. For aluminum boats, for example, Mobihel car enamel is suitable.

Antifouling paint

Special paints are applied to the bottom, which is located in an environment where living plant cells grow on it and animal microorganisms adhere.

The special paint for boats is called “anti-fouling”, i.e. it contains elements that prevent various forms of life from settling on the hull. For example, International Trilux paint has proven itself well.

Features of painting boats

Boats are made from a variety of materials - PVC, wood, their base can be rubber, fiberglass, but the most popular and high-quality boats are those made of aluminum. Modern boats are made from duralumin (duralumin) - a high-strength aluminum alloy with the addition of magnesium, copper and manganese. The weight of a duralumin yacht or boat is small, but the products are very reliable, resistant to damage, and easy to transport and launch.

The technique of painting boats has its own specifics. The paint should increase the service life of the coating, at the same time have high moisture resistance, and be suitable for swimming in different types of water bodies. It is equally important that the paint and varnish material gives the product an attractive appearance and enhances its aesthetic qualities. If the finishing varnish usually has a transparent texture, then the paints are tinted in a variety of colors. On some types of bases, paint is difficult to apply and rolls off, so you have to increase the level of adhesion in different ways.

Aluminum boats

Painting of aluminum watercraft can be done using two methods:

- Powder. For this purpose, powder paints are used, which are applied to the body after it has been cleaned and chemically prepared.

- Anodizing. It involves the creation of an oxide film on the surface of aluminum by galvanic method (anodic polarization in a conductive medium). At home, such coloring is possible, but special equipment is required.

The first method is difficult to implement. After cleaning and preparation, paint is applied and the boat or its parts are placed in a thermal chamber. There, under the influence of high temperature, the powder melts, forming a very strong protective layer. The service life of objects after painting will be as long as possible.

If small defects appear on the bottom or sides, you can get rid of them using a special pencil. The difference between the two listed methods is the resulting color. If, when anodizing, the boat will have a beautiful gray tint, then with powder coating you can get any desired tone.

PVC boats

Such products are very popular among fishermen because they are cheaper than aluminum ones. They replaced inflatable products. They need to be painted with paints and varnishes that are resistant to mechanical and chemical influences. Also, paints must be quick-drying, impart high strength to the coating, and have water-repellent properties. You should purchase paints and varnishes for rigid polyvinyl chloride, profiles, and other PVC products.

In industry, a new paint and varnish material is used for such objects - PaliPlast RP 2040. The boat can be painted with it after careful preparation and degreasing using a PVC cleaner.

Wooden boats

With the advent of modern materials, wooden boats are losing their position, but are still used. Some people construct wooden watercraft themselves, because it is inexpensive and reliable. But such objects rot from constant exposure to water, crack, and fail. Wood should be painted regularly, at least once every 1-2 years.

First, the boat needs to be tarred, which is long and difficult. Next, the body and bottom are sanded with sandpaper to make it smooth. Smooth surfaces are painted with a roller; in hard-to-reach places, they are tinted with a brush. At least two coats of paint should be used to make the coating more durable. The first layer will be thin, the subsequent ones will be thicker, so there will be no streaks left on the boat. Typically, paints based on lead white with the addition of colors are used. Finally, varnishing is performed. Metal parts are painted with red lead and glyphthalic enamels.

Plywood boats

Plywood has poor resistance to water, so without body protection the material will quickly delaminate. First, drying oil is applied to the plywood, and then it must be primed. There is only one paint that can protect the base of the boat - epoxy. Paintwork will make the plywood harder, stronger, and its service life will increase. It is better to do the painting yourself - hiring professionals can cost more than the price of the boat itself.

Boat painting

As the boat is used, a thick coating of bacteria and small aquatic organisms appears on its bottom, which causes a decrease in speed, malfunction of instruments and a number of other problems. To avoid troubles, it is recommended to apply special alkyd or epoxy paints below the waterline. They are also called “antifouling” or “antifouling” because they do not allow plaque to form.

Before applying the composition, the body is cleaned with a special remover, and the surface is examined to identify defects and damage. If they exist, the boat is first repaired. Then the base is primed and covered with antifouling. It is better to use epoxy coatings with the addition of copper oxide - their price is higher, but the products must be used once every few years. Application is carried out with a roller, brush or spray gun; in industry, the airless spray method is used.

Caring for a plastic boat

Boats made of fiberglass and other types of plastic lose their visual appeal and shine as they serve. But they do not rot and there is no need to renew the color on their bottom and body every year. The disadvantages include the inability to paint the product at home - you will have to contact specialists, which is expensive. Therefore, such objects are painted only when they are significantly worn out, when there is no other way out.

Priming

When choosing paint for an aluminum boat, you need to consider what kind of primer it has been pre-treated with.

The following can be used as a primer for various paints for an aluminum boat:

- Soil VL-08.

- Soil VL-02.

- Soil GF-031.

- Zinc white.

- Zinc yellow or crown green.

- White epoxy paint EP-51.

Of course, this series can be continued.

Composition of paints and varnishes

Various primers and paints are one-component or two-component

One-component - dry after complete evaporation of the solvent. For example, one-component enamel “Krasko Nerzhalux” is applied to a phosphating primer.

Two-component - dry by reaction between two or more components. They have great resistance, but also increased toxicity. It is recommended to spray them only in a respirator.

An example of a two-component paint is EP 140 enamel. This epoxy enamel is well suited for painting an aluminum boat; it is applied over an epoxy (EP), acrylic (AK) or VL primer.

Types of painting materials for the body

Modern technologies have made it possible to choose paints for the body, which is exposed to harmful weather factors, temperature changes, humidity and ultraviolet radiation. There are four types of coating: • Alkyd; • Epoxy; • Linear polyurethane; • Acrylic urethane. The first option is oil paint, which has proven itself to be effective in resisting negative weather factors. Epoxy-based paint for boats, ships or boats also serves as a sealant, since such products are created on the basis of resins, similar in composition to materials for the construction of watercraft. Linear polyurethane is difficult to apply, as it is harder, but more durable and reliable. Acrylic urethane paints have a similar composition to car paints, so they can boast enviable resistance to external destructive factors.

Paint schemes

Since primers, paints, and varnishes are often purchased separately, and not in any separate series, it is very important to know the degree to which certain paints and varnishes can be combined with each other.

If your painting scheme is as follows: you applied acid prime and acrylic primer to the cleaned hull of the boat, then the paint should be acrylic.

Another scheme: two layers of epoxy primer are applied to the cleaned bottom, and epoxy paint is selected.

When priming and painting a boat, you need to wear a respirator, preferably a carbon one. It will not get rid of the smell, but it will retain particles of fine dust and aerosols (if you paint with a sprayer).

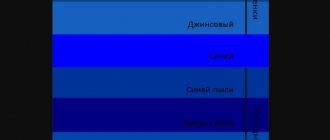

Is color important?

Apart from some restrictions on the color of boats provided for by law for law enforcement agencies, choosing a paint tone is a purely individual matter. But experts have noticed that dark paints for yachts and boats provide a much shorter surface service life than if painted in light colors, but both of them can always be ordered through us. The advice to choose light shades is especially important for vessels that are planned to be used in warm waters, when reflective factors have a mostly destructive effect.

Choice

There are many paints on sale, both expensive, imported, and more budget-friendly domestic ones.

It’s possible that cheap paint will work well, but people are usually afraid to try, because before that a lot of work has been done on cleaning and priming, a lot of effort and money have been spent, so many try to paint only with materials that have been tested by experience or those that were recommended.

Paint and paint systems Duxone, HEMPEL, Tikkurila have proven themselves well.

The advice is the following: before making a decision to buy paint, it is better to look at the forums to see who painted it or not and read reviews about the quality.

When choosing a paint color for your boat, keep in mind that paints fade over time and, strange as it may seem, white fades the most. But rich colored paints are more durable.

High-quality paints fade more slowly.

Method for determining paint compatibility

If you decide to partially paint the boat, then you definitely need to find out what paint it was originally painted with. Old and new paint must be compatible.

You can check paint compatibility experimentally. You can do this as follows:

- Generously wet a small piece of rag with 646 solvent.

- Place a larger piece of plastic wrap on top.

- Seal the edges of the film with tape.

- After a day, see if the paint under the film has not swelled, then you can apply any primers and paints to the surface, even epoxy and polyurethane paints and varnishes.

It is not recommended to use red lead, lead or titanium paints for painting an aluminum boat; they all destroy aluminum. Especially the rivets get it.

Preparing and painting the boat

To prepare the surface for painting, you need to do the following:

- Clean the boat from dirt. Dirt, sand, and algae must be removed from the object; this should be done by pulling the boat ashore. You can use paper clips, rags, brushes as tools; water from a hose under pressure works well.

- Remove equipment that interferes with painting. If the casing is removed, it is advisable to remove it too. This will help you paint more thoroughly, without leaving cracks or unpainted areas. The remaining parts must be covered with film and construction tape before work.

- Remove wax coating. If there is any, it must be wiped off with a solvent. Grease and wax are easily removed with a sponge soaked in Awl-Prep. Afterwards, you should slowly run your hand over the surface of the product - there should be no smooth areas like a candle left on it.

- Repair all broken and damaged items. Dents, cracks, pits, and areas of corrosion must be eliminated. Otherwise, the product will have a short service life. Most defects can be easily eliminated by filling with epoxy resin.

Often old paint remains on the boat. You can leave the layer if there are no visible damages, smudges and it is not too thick. To improve adhesion with new paint, you can simply wipe the coating with an abrasive, such as a metal sponge.

When paint cracks or peels, preparation must be more thorough. There are two ways to remove the paintwork: sanding or washing. The first option is more convenient and faster. Use a sandblasting gun or sander, drill with a brush as an attachment. Small surfaces can be sanded manually. When cleaning an aluminum boat, it is important not to scratch the anodic layer, which has a yellow-gray tint. Damaged areas on the anode layer must be sanded well.

Washing off paint

Washing is preferable to sanding, but this method is labor intensive. The whole process should take place in the fresh air, in warm weather, in dry weather or in a well-ventilated area. It is better to wash in parts, treating areas of no more than 1-2 square meters. m. To speed up the reaction, cover the object with film.

Corrosive-inert agents are used for rinsing:

- Elcon S. Removes bitumen, alkyd, epoxy and other paints well. The liquid is applied to the base and left until the old paint swells and cracks. Then remove the paint with a spatula or scraper.

- NEOMID. This product is considered reinforced and is used on thick layers of paintwork materials, as well as on particularly durable compositions - epoxy, phenol-formaldehyde, polymer. 10-25 minutes of exposure is enough to completely wash off the paint.

After using the remover, it is important to take measures to prevent damage to the new coating that will be applied subsequently. To do this, wipe the boat with solvents - acetone, white spirit. Afterwards, dry the object well and proceed to the next stage.

Rust removal

Against rust, which often forms on ferrous metal substrates, special converters should be used. They prevent the process from progressing and also serve as a prevention of corrosion. The converters are applied before the paintwork; as a result, after 30 minutes a white coating appears on the surface. After removing it, you can continue working on painting the boat.

Puttying

The use of putty when repairing boats is not recommended, especially when it comes to an aluminum product. Putty materials are hard, so with the inevitable vibration of the body during operation, the applied layer will crack. Also, putties are highly hygroscopic and absorb moisture, which is why they do not last long. Only epoxy products do not have such disadvantages. They are recommended to be used when there is an urgent need to repair chips, defects, or level the surface. If the defect is large, putty is applied to a layer of fiberglass.

Padding

Primer, unlike puttying, is a mandatory stage of painting a boat. Moreover, the primer must be applied as quickly as possible after removing the old paintwork and degreasing. If “bare” aluminum is left exposed to air, it will quickly darken and the paint will lie unevenly on it. The primer will ensure good adhesion of the base to any type of paint and will reduce water permeability. Specialized primers are used - for example, VL-023.02 or epoxy. After applying such products and painting, the product can be used without problems in the most aggressive conditions in any weather.

The priming procedure is as follows:

- mix the base and acid diluent;

- leave the product for 30 minutes;

- apply a layer to the boat and let it dry;

- apply another layer.

Coloring

The boat should be painted on a dry, warm day, this will allow you to get an excellent result. It is desirable that the humidity is no more than 60%. Before purchasing paint, you need to make sure that it is compatible with the primer. Immediately before painting, you need to lightly sand the primed base with fine-grained sandpaper.

The paint should be applied with a roller, brush, or spray gun - as desired. You need to start from the bottom. In any case, small areas are tinted with a brush. After the first layer has completely dried, it is recommended to lightly sand it with the same sandpaper (grain 300). After that you should apply another 1-2 layers of paint.

If you decide to paint a boat in camouflage, it is important to get natural material - leaves of cattails, ferns, and various trees. The primed base must be covered with leaves, painted with three shades of paint, and then varnished.

Painting the bottom of the boat

This part of water transport bears the highest load, because it is exposed to water, salt, and wears out faster. XC-436 shipbuilding enamel is well suited for painting the bottom, increasing the corrosion resistance of products. It is applied at least to the waterline and to the entire underwater part of the boat. The product goes well with antifouling agents and primers. Paintwork materials are applied in 2-3 layers in any way. If the boat will be stored in water, the top of the XC-436 is once again covered with antifouling.

Painting wooden parts inside the boat

For this purpose, it is recommended to use special alkyd-polyurethane-based yacht varnishes. They provide a durable, weather- and water-resistant coating that does not react to the effects of petroleum products and household chemicals. Varnishes highlight the structure of wood and protect it well from ultraviolet radiation.