Marble is one of the most popular finishing materials. Architects and sculptors valued it in ancient times, and it is still valued today for the beauty of its texture and wide range of colors. It is indispensable for creating noble, presentational interiors and facades.

Marble is easy to process, durable when used in different climatic conditions, and a large number of deposits around the world makes the cost of marble accessible to different segments of the population. Marble is produced in the form of sawn, ground and polished slabs of various thicknesses; fragments and waste of large products are processed into crumbs of different fractions.

Obtaining marble chips

Crumbs of natural minerals began to be used in construction as soon as they learned how to process stone, striving for waste-free valuable material. Marble from different deposits, with its variety of natural shades from white to dark green and almost black, helped the ancient Greeks and Romans create unique mosaic panels on the floors, walls and ceilings of their temples and villas, some of which have survived to this day. All marble waste was crushed into smaller stones and put back into use.

Nowadays this eco-friendly stone is especially valued for its elegance and beauty. In production, all waste after cutting stone into blocks and slabs is crushed, divided into fractions by sifting, the crumbs are cleaned of dusty components by washing, dried and packaged in moisture-resistant bags.

Features of applying marble mixture

Before applying any finishing coats, the substrate must be carefully prepared to ensure proper adhesion of the two surfaces. The preparatory stage when using marble plaster is carried out in different ways, which depends on the parameters of the crumb.

• A mixture based on small and medium-sized fragments of marble is applied to a well-prepared base with a perfectly flat plane. To do this, the surface is leveled using fine-grained putty and, after drying, sanded with a trowel mesh.

Classification of marble chips depending on the size of the fraction

In modern construction, design and arts and crafts, the use of marble chips has not lost its relevance. Stone processing plants produce chips from 0 to 20 mm without color separation:

- marble flour (dust) - 160 microns...2 mm;

- crumbs (sand) - 2...8 mm;

- crushed stone (gravel) - 15...20 mm.

Marble chips can be of different sizes, each fraction is divided in increments of 0.5 mm, and the material is marketed with the following markings:

- 0.2-0.5 mm;

- 0.5-1 mm;

- 1.0-1.5 mm;

- 1.5-2.0 mm;

- 2.0-2.5 mm;

- 2.5-3.0 mm.

Quality characteristics of the material

The quality of decorative materials that go on sale is regulated by GOST 22856-89 “Crushed stone and decorative sand from natural stone.” Marble chips can be purchased in bulk and in bags.

Advantages of natural material:

- environmental friendliness and safety of use inside the house and in the local area;

- natural palette, which depends on the place of extraction and the content of certain chemical elements in the composition of the stone;

- ease of processing, use, possibility of decoration and coloring;

- moisture resistance - water absorption at a level of only 0.75%;

- wear resistance and strength, which even in conditions of constant humidity decreases by a maximum of only 30%;

- no sparks forming upon contact with metal.

Areas of application of marble chips

Marble chips are a universal material; they are used in the production of construction and paint materials, landscape design, production of interior items, and agriculture. Every year, people are increasingly mastering the areas where this natural material can be used.

Landscape design

Marble chips in landscape design are used to improve the territory of parks and gardens; in climatic conditions, they do not change color and are resistant to temperature changes. Crumbs are used as a filler for decorative concrete coverings of recreation areas, linings of decorative pools, embankments. Slabs with marble chips are used to pave paths and recreation areas of private areas and public recreation areas.

Marble chips are popular for backfilling paths and mulching plantings of ornamental shrubs.

Marble chips in construction and architecture

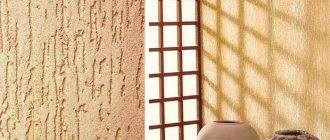

In the production of various building mixtures, decorative plasters and paints, marble chips of different fractions are used.

The finest dust is used as a filler for interior paints; it gives the compositions unrivaled pearl shimmer, light reflection, whiteness and depth.

The middle fraction—sand with different grain sizes—is used for the production of decorative plasters of fur coat, bark beetle, and pebble plasters. The larger grain serves as a filler for façade compositions, while the fine grain is widely used in interior decoration.

The coarse fraction, crushed stone, has found application as a filler for mosaic concrete for various products: slabs, countertops, window sills, in landscape design, and serves as a filler for non-sparking floors in industry and terrazzo floors in interiors. Another area of application for marble chips is in the manufacture of roofing materials by spraying onto a bitumen coating.

Does marble need maintenance?

If it is used for interior decoration of a house, then it does not require any special care. If it is used as an embankment or for a dry stream, then over time it will become dusty and dirty from rain.

In this case, you need to collect the top layer of crumbs and place it on polyethylene or a tarpaulin. Wash it with high pressure water from a hose and let it dry.

To bleach white marble, you need to place it in a basin and add a little bleach. It is better to soak the pebbles overnight, stirring them periodically with a mop or broom. After bleaching, it is rinsed with clean water and laid out on a tarpaulin. When the crumb dries, it needs to be returned to its place, and it will again delight you with an amazing snow-white shade.

Marble serves as an excellent material for creating extraordinary landscape decor; it can be used not only as a background for plants and flowers, but also act as a bright composition in your garden. In our next article, read about the use of decorative bricks.

Qualities and advantages of marble chips

Marble chips, like marble itself, are an environmentally friendly material with high strength, non-flammable and resistant to many aggressive chemicals, durable, highly decorative and a wide range of colors. Unlike many types of artificial materials and coatings, marble chips are harmless to human health and can be used in the decoration of medical and children's institutions, and in food production.

Like all materials of limestone origin, marble is spark-proof; marble chips are used to cover the floors of explosive industries.

Compositions with marble chips are applied in a thin layer, so they have little weight and consumption.

Where is it used?

The variety of sizes and shapes, the excellent strength of marble chips allow it to be used for a wide variety of home design elements. Most often it is used to create tracks; it can also be used for:

- Decorating flower beds, lawns, ponds and swimming pools.

- Creation of decorative panels.

- Decoration of flower pots or borders.

One of the faithful assistants when creating panels, flower beds and paths from marble chips will be border tape. It performs the function of dividing space, while having good flexibility and strength.

Thanks to this, you can create any shapes and designs you want in your garden.

By edging the path with curb tape, you will prevent the marble from scattering and keep the path in its original shape for a long time.

How it is made

Stone chips of a certain fraction and acrylic paint are used as raw materials for the manufacture of the material. If the initial raw material is stone chips not sorted into fractions, then the first technological stage will be separation into fractions by sifting on a vibrating screen (vibrating screen).

The necessary raw materials for the production of painted crushed stone are extracted from the quarries Source avistd.ruThe next stage is painting, for which a painting hopper is used, the principle of which is similar to a concrete mixer. The volume of paint loaded into it is about 20% of the volume of loaded crushed stone. After coloring, the crushed stone is moved to a drying chamber; after drying, the stone is packaged in bags weighing from 2 to 20 kg.

There is a risk of purchasing low-quality decorative material. These are mainly products of small enterprises, which, at the expense of quality, can save on:

- feedstock;

- the amount of paint placed in the hopper;

- drying chamber (drying is carried out simply in air on plastic film).

A little about texture and material consumption

When applying this finish to the wall, a spectacular rough surface is created. The degree of roughness may vary depending on the size of the granules, which can be as follows:

- Small – less than half a millimeter;

- Medium – up to three millimeters;

- Large - over three millimeters.

In this case, we are talking not just about the final texture, but also about the consumption of plaster per square meter of surface. So, if with small fractions the consumption can be 1-3 kilograms, then in the case of the largest ones it reaches 8 kilograms per square meter.

How to apply stone chips to a wall

All of the above qualities largely depend on how well the wall is prepared for work. In this case, the preparation depends on the size of the mineral fragments in the composition itself.

- Venetian style. The wall must be perfectly flat, for which it is treated with thin putty and then sanded with a fine abrasive;

- Large grains. Marble chips of this size are large enough to hide small irregularities, and therefore can be applied to rough plaster;

- Medium and small grains. Finishing putty is carried out, which should be processed with a grinding machine before work.

General tips for surface preparation

Let's first define what exactly this surface is. Fortunately, the properties of marble chips make it possible to apply such plaster on a variety of surfaces: particle boards (chipboard, fiberboard, etc.), drywall, concrete, brick and plaster. In other words, this finishing method is suitable for almost any home and any room. In general, the process of preparing walls is standard:

- Leveling the surface - differences should not be more than 5 millimeters;

- All seams are unstitched and treated with a primer;

- Cracks and other defects should be eliminated with plaster or cement mortar;

- The entire surface must be cleaned of old finishes and poorly secured fragments;

- It is necessary to thoroughly clean the wall or floor from dust and grease stains so as not to reduce adhesion;

- The surface is thoroughly dried. The required wall humidity should not exceed 10 percent.

Material application process

We will work with a trowel, onto which a small amount of diluted plaster is applied with a trowel. In this case, the latter must be diluted in accordance with the instructions on the packaging, leaving it in this state for about 10 minutes before starting to apply it to the wall.

You need to work from the bottom up, trying to keep the tool clean. The thing is that filler particles stick to the steel surface of the grater, and after several approaches the tool must be cleaned. As for the layer, you should not make it more than 2 millimeters thick. Otherwise, keeping the material on the wall will be problematic and over time the granules will begin to fall out.

Once applied to the surface, the marble will begin to polymerize, and the process will take approximately half an hour. Only after this period can you begin further processing - leveling the surface with a metal float. In this case, do not press the tool too hard so that the granules do not fall out of the binder. As for the final hardening of the composition based on marble chips, this occurs within about two days.