Technical characteristics and scope of material

Painting fiberglass canvas consists of fiberglass threads, like glass wallpaper, but the difference is that the web is not made on machines. The manufacturing process of the “wallpaper” in question is as follows: fiberglass comes under a press, as in the process of manufacturing sheets of paper. The result of such pressing is smooth, thin sheets, the surface of which is very smooth. The density of compressed fiberglass is 25-50 g/m2.

Although the process of making fiberglass webs and paper are to some extent similar, the difference between them is colossal - unlike paper sheets, they do not accumulate statistical electricity on their surface, and they are also not afraid of water, mechanical damage, or chemical reagents. Dust is also not attracted to them and, among other things, they do not burn. It is difficult for some to imagine what such a finishing material looks like, therefore, you can watch a video showing how to use painting fiberglass in this article.

Similar characteristics of cobwebs and paper include their composition, namely, the ingredients included in its composition are exclusively natural, as in paper, they are also a non-allergenic material, and they allow air to pass through perfectly. The difference between fiberglass and glass wallpaper is the absence of a wicker pattern and relief on the surface of the former. But this also has its advantages, if there are no prominent elements on the surface, it means they can be painted an unlimited number of times, no relief - no problem.

How to choose

Typically, glass wallpaper is selected according to the pattern, and the quality is determined by the density of the material in the roll. But it’s worth saying that not everything on the wall looks as voluminous as it does on a roll. To make the pattern look clearer, some manufacturers use fluffed threads. When sticking to the wall, all the fibers are pressed, the volume goes away. So the volume of the roll is not a guarantee that the design will be clearly visible on the wall. The solution is to purchase proven brands that guarantee a certain quality.

You need to choose not only by appearance

The situation is practically the same with the density of glass wallpaper “to the touch”. To give them additional strength, some manufacturers impregnate the canvas with starch. When applied with glue, this impregnation gets wet, the surface becomes loose, which is why it absorbs a large amount of paint.

Look at the technical specifications

How to determine good glass wallpaper in this case? View technical specifications. There is a line there - density. The higher the number, the denser the wallpaper (normal density is about 145 g/m2). If this indicator is not present, there is a roll weight. In this case, too, the heavier the roll, the greater the density of the material. But in the case of weight, you also need to look at the length of the canvas in the roll - it can be very different - from 12.5 meters to 50. There is another way out - trust trusted manufacturers or try it on a small piece - glue it, then paint it. Only the question of where to get this piece remains open...

What else is worth knowing about glass wallpaper...that they come in two grades - first and second. The first grade is of good quality and usually comes with a warranty. The second type is something like a lottery. They may be wow, they may not stick well, have a large number of defects, etc.

Glass wallpaper in the interior

A few words about marriage. It occurs even with good manufacturers - the threads are broken, they lie wrong, etc. This place is marked on one of the edges of the roll with a glued black stripe, and 50 cm (penalty) is added to the length of the roll. When purchasing a roll in transparent packaging, inspect the ends. The fewer black “markers”, the easier it will be when cutting.

Manufacturers

And finally, about trusted manufacturers. We can definitely recommend the Wellton and Oscar brands. Any collection, any roll is of good quality. Even the second grade is not about quality, but about non-standard length (so you can save money).

It's better not to save

According to the pricing policy: Welton is more expensive, there is a larger selection of patterns, you can repaint it up to 20 times; Oscar - cheaper, less texture, can be repainted up to 10 times. So there is a choice for every budget.

Choosing adhesive for fiberglass

Many inexperienced consumers do not know what to glue fiberglass to. Naturally, ordinary wallpaper adhesive is unlikely to be suitable in this case. Glue for fiberglass must have a high degree of strength and adhesion. When deciding what is the best way to glue finishing material with a fiberglass base, finishing experts recommend giving preference to a special adhesive composition designed for fabric made of glass threads. Today, the building materials market offers a huge variety of such glues.

As an option, you can consider the procedure for creating glue for fiberglass with your own hands. It is not difficult to carry out such work, because the technology for creating glue for fiberglass is very easy. When purchasing a special fixing compound, consumers often ask sellers whether it is possible to glue fiberglass to PVA? The answer is clear - yes, this can be done. Moreover, PVA glue, sold by many office supply stores, is the basis for a self-prepared adhesive mixture. PVA glue for fiberglass is used because its composition has a high level of reliability and helps to obtain durable bonding of surfaces.

Adhesive for decorative fiberglass fabrics is available in two versions:

- Ready-made glue for fiberglass, the use of which can be started immediately after the container with the composition is opened.

- Dry adhesive mass, the use of which can be done after dilution with water in the proportions recommended by the manufacturer.

Among the most famous and reliable adhesive compositions for gluing fiberglass are:

- Bostik. In the production of adhesive compositions for the construction industry, Bostik glue for fiberglass takes a leading position. An advantageous combination of components ensures high quality coating when using this type of glue. In addition, the cost of Bostik glue is affordable and accessible to any average buyer.

- Kleo Ultra. This type of glue is distinguished by its durability, ease of use, and efficiency. It contains additives that prevent the development of fungus, modified starch, as well as several other useful components. The advantages of Kleo Ultra glass wallpaper adhesive include the following:

- Easy application;

- Easy preparation;

- Low consumption;

- Environmental cleanliness and safety.

This glue is diluted with water according to the manufacturer's instructions. The composition is ready for use 5 minutes after diluting the dry mixture. The advantage of the composition is that after its application no stains remain on the surface.

Wellton. This type of glue helps solve the problem of how to stick fiberglass on walls for further painting work. Welilon glue is a certified product that has such advantages as:

- Fire safety. If there is open contact with fire, it does not release toxic volatile substances into the air.

- Ecological cleanliness. The glue contains no components hazardous to the human body.

- High level of hygiene. Throughout the entire period of operation, the glass sheet can be washed as many times as desired without fear of its damage or premature loss of its attractive appearance.

OSCAR. This glue has a number of advantages over other similar products:

- The composition is safe for the human body, and this is confirmed by sanitary and epidemiological surveillance.

- Efficiency and cost-effectiveness of use. Only 0.5 kg of dry mixture is diluted with a large amount of water (8-10 liters).

- Ease of preparation. To dilute the powder, the water does not need to be heated. The composition is poured into cold water and mixed thoroughly, and the mixture can be used 10 minutes after mixing.

- Long shelf life of the finished product. In a closed container, glue of this brand can be stored for up to 2 months.

- Easy to transport.

- Economical. The finished adhesive composition in an amount of 0.25 kg is enough to process 1 sq.m. glass sheet.

Paint selection

Glass fiber canvas can be painted with materials that are suitable for glass wallpaper. Water-based paints are most suitable for this purpose; they do not affect the performance qualities of the main material. Similar paints do not have a nasty odor and are not harmful to humans. It contains only environmentally friendly elements (polymer materials, water, targeted additives). There are several types of water-dispersion paints, they are described below.

Acrylic based paints

These paints are the most common; they have many good qualities. Easy application and quick drying, together with a low price, are the main positive qualities. Paints can be applied to fiberglass canvas or wallpaper, the coating will be resistant to friction and water. The materials adhere perfectly to the surface and give an attractive decorative look. A large number of paint brands are sold in white; they can be tinted to any shade.

Latex based paints

Such materials have a higher price. These are water-dispersion based

, without chemicals, not harmful and suitable even for children's rooms. The composition contains real latex, which makes the coating more resistant to water.

Surfaces with latex-based paints can sometimes be washed or wiped with a damp cloth. This material is quite economical and makes it possible to obtain reliable results. If acrylic materials give a matte film, then latex materials give a matte, semi-gloss, glossy film.

Silicone paints

Enamels containing silicone are not afraid of dirt, this is their main advantage. There are no aggressive chemical components here either, thanks to this the material is completely non-hazardous. Silicone paints, as a rule, will last up to 25 years without losing their external gloss, but their price is much higher among water-dispersion compositions. The material is considered moisture-resistant, vapor-permeable, heat-resistant, and is not exposed to mold, mildew, or ultraviolet radiation.

Features of application

Fiberglass is used to secure finishing putty or other finishes. This thin and lightweight material can be used at any angle and on any surface. In addition, it improves the surface structure and ensures its wear resistance.

How and why to glue under putty

The fiberglass must be glued under the putty, otherwise after removing the finishing material the cobwebs will follow it.

If the walls were painted using fiberglass, the seams, joints and texture of this material will be noticeable.

Fiberglass is glued as follows:

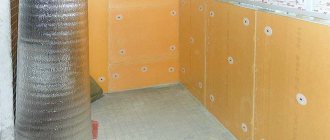

Preparatory work. Before gluing the web, you need to prepare the wall. To do this, putty is applied to the drywall, which hides irregularities, joints, etc.

It is important to consider the following rules:

- Before filling, the walls should be cleaned of dirt;

- the places where irregularities were sealed should not be convex. To do this, you can use surface grinding;

- if there are still bulges, you can apply the putty again;

- Before applying fiberglass, the wall should be cleaned of dirt and sanded.

- Gluing fiberglass:

- the first layer should be glued from the corner;

- The glue itself must be applied to the wall, and only then the cobweb should be glued;

- It is better to cut the required number of sheets in advance, since gluing must be done continuously to avoid visible joints;

- then the excess glue and air are smoothed out with a spatula;

- use a knife to remove excess material;

There should be no joints between drywall and fiberglass in the same place, as the seam may crack.

Is it possible to glue fiberglass under wallpaper?

Fiberglass is a reinforcing material that is used for painting surfaces. It can also be used under wallpaper, but before doing this, be sure to treat the surface.

What density of the material should be

Painting fiberglass is made from quartz sand. It is sold in rolls of 50 meters and a width of 1 meter. For wall finishing, the density of the material should be 25-50 g/m2.

When choosing fiberglass for walls, it is better to give preference to a denser texture.

Where else is it used?

Fiberglass has a wide range of uses. It is used to make:

- Plumbing parts: dry closet, shower stalls.

- Sports goods - oars, ski poles.

- Creation of boxes and containers for household purposes.

- Medical products – fillings, prostheses.

- Tubes for household use - antennas, various holders, etc.

- Electrical products - indicators, fuses.

What is glass wallpaper

Fiberglass wallpaper is a finishing material for walls and ceilings. Most often used for painting. Fabrics, which are called “glass wallpaper,” are woven from fiberglass on special machines. By using fibers of different thicknesses and their different weaves, different patterns are obtained. There are not as many of them as on regular wallpaper, they are not too pronounced. And this is considered one of the disadvantages of this finishing material. But practicality, durability and the ability to repaint them up to 20 times outweigh this drawback.

Types of glass fiber matting type

There are drawings that are almost invisible, which after painting just give a slightly rough surface. The most common type is matting. It is called so because the weave is made in the same way as coarse cloth was previously woven - matting. There are small, medium, large. The difference is visible in the photo.

Herringbone, checkerboard and diamond patterns are also widespread. They also come in small, medium and large. They differ in the “scope” of the pattern. In addition to these types, there are other weaves, but they already belong to the category of designer or collectible and cost more.

Herringbone and diamonds are also common

This material is sold in rolls, usually 1 meter wide. Roll length - from 12.5 m (50 are also available). Price per roll - from $20 to $50. The cost depends on the length of the material in the roll, the complexity of the design, and the manufacturer.

Finishing

Typically, fiberglass is used to cover a ceiling intended for painting or decorative plaster. And if the surface does not need to be treated in any way before applying the plaster composition, the fiberglass should be prepared before painting. If this is not done, the material will greedily absorb paint, which will lead to a very large waste of it.

Preparation methods:

- Putty and sanding. The best option allows you to get a high-quality smooth base for painting.

- Padding. The composition must be taken from the same manufacturer as the paint that is planned to be applied to the ceiling. It is advisable to prime several times.

- Application of thinned paint. A more liquid composition will act as a primer layer.

For painting, you can use water-based, water-dispersion or acrylic interior compositions, both snow-white and tinted.

How to properly glue fiberglass?

Fiberglass is used, performing 2 stages of work:

- Manufacturing a matrix, which is a special form for the future product.

- Creation of any item.

Compositions (parts by weight) for gluing fiberglass when sealing cracks.

When preparing to glue fiberglass, you need to have the following materials and tools on hand:

- structural fiberglass;

- epoxy resin (with hardener);

- polyurethane foam;

- spatulas;

- construction universal putty;

- emery cloth;

- a brush with stiff bristles;

- paraffin or stearin;

- stationery knife or jigsaw.

The main thing is to follow the manufacturing technology so that the product is more durable - only then will it last a long time.

All work must be performed according to the following instructions.

Rules for laying fiberglass on a yacht hull.

To make a matrix, a frame is made for it, which is also called a blank. It is necessary to accurately calculate all dimensions, which depend on the shape of the product that will be manufactured. Any suitable materials, such as wire, wood or plastic, will be useful for the frame.

Perhaps the product will have a complex shape, then polyurethane foam is used to create a surface layer of the matrix. When determining the size of the frame, you should usually be guided by the fact that there will be a layer of mounting foam on it, the thickness of which will be 3-4 cm.

A layer of foam with an installation thickness of 3–4 cm must be applied to the blank. It is better to apply several layers. To treat a surface with layers of foam applied, you should use the following materials:

- stationery knife;

- sandpaper;

- razor blades;

- jigsaw;

- Bulgarian

Impregnation of fiberglass is best done on glass, then the resin will lie evenly.

Next, prepare a construction-universal putty.

The prepared putty or other type of composition used to mask the pores is applied to the matrix, leveling it. The dried matrix is sanded using sandpaper. This operation must be repeated several times to make the surface of the product soft.

The matrix is covered with a special material, which is used to prevent sticking to the shape of the product. Such material is stearin, paraffin or parquet polish, etc. When the composition has dried, it is necessary to polish the surface with a special cloth.

The resin is mixed with the hardener in the required proportions. It is then applied to the matrix using a spatula. The layer should be thin. After it becomes hard, apply the next layer.

To make the epoxy resin harden faster, you can dry it with a hairdryer.

Fiberglass fabric is coated with resin by rolling the material using a special rolling roller or by pressing and compacting it with a brush with fairly coarse bristles. It is necessary to ensure that the fiberglass fabric is completely impregnated with air, which must be removed from the material. Otherwise, it may lead to delamination and swelling in various places.

If the surface has a complex shape and folds form on the fiberglass, then they are cut off using a knife or scissors, pressing the cut edges quite tightly to the entire surface.

Then the matrix and the product are again coated with resin for gluing the fiberglass. This is repeated until the required strength of the product is achieved. You can make from 3 to 5 layers of fiberglass, and then remove the finished product from the mold. After this, the product is painted and varnished.

Preparatory stage

Fiberglass can be applied to any surface - plaster, drywall, extrusive polystyrene foam used for noise and thermal insulation of ceilings, polystyrene foam, wood, fibreboard, MDF, chipboard and even PVC panels. Before pasting it is necessary to carry out a number of preparatory work:

- Remove the old coating - whitewash, plaster, wallpaper, paint layer. If the adhesion is strong enough, you can use special paint removal liquids and solvents. It is recommended to remove a thick layer of plaster with a sharp metal spatula, then rinse with warm water and detergents. Read more about methods for removing different coatings here.

- Potholes and chips formed after removing the old layer should be puttied and primed.

- After the putty and primer have dried, putty in the cracks and then prime the entire ceiling with a deep penetration compound to improve the adhesion of the web to the surface.

- When gluing drywall with gossamer, it is necessary to putty the joints and recesses in which the screws are recessed. Dry surfaces can be primed or instead of a primer, apply a thick layer of spider web glue so that it is partially absorbed into the drywall, creating a reliable base for further finishing.

- A painted ceiling with a durable paint layer should be treated with coarse sandpaper for better adhesion and primed before gluing it with gossamer.

- Old PVC panels also need to be sanded to create a rougher surface.

Paintable fiberglass is an excellent material for reinforcing painted surfaces

What do you need to know about preparing for painting? The final interior decoration is the stage that completely transforms the room being renovated. But in order to ensure that preparation flaws do not appear on the walls or ceiling over time, it is advisable to do all preparatory work using the latest technologies. Modern materials make it possible to prepare the surface to be repaired so well for wallpapering or painting that even after a long time the base will not become covered with cracks or chips and, therefore, the finish coating will not be damaged.

Application and putty of fiberglass

As noted above, gluing a cobweb is quite simple and you do not need to have any special skills to carry out this stage of work. However, before gluing fiberglass, you need to clearly understand the basic rules of gluing. So, the first thing you need to do is apply glue to the surface of the wall. However, it is necessary to prepare it in advance. After applying the adhesive solution, lay out the first strip of material and carefully fix it by lightly pressing along the edges. Then, apply glue to the rest of the work surface and attach the rest of the canvas.

Then it needs to be further processed using putty. This is how the surface is prepared for painting. It is applied after the installation of the Gossamer fiberglass itself has been carried out. Doing this is quite simple, and there is no need to have any special skills. All this can be done with your own hands.

By the way, we strongly recommend watching a useful video instruction on how to properly glue fiberglass web:

https://youtube.com/watch?v=tafb6MYDHHM

As for the actual laying of individual sheets, they should not be joined end-to-end, but overlapped, overlapping by a few centimeters. After this, it is necessary to cut both canvases along the connection line at the place where one of the canvases overlaps the other. You can cut them using a sharp construction knife. The remaining scraps can be thrown out, and then the sheets can be finally secured end-to-end along the new joining line.

In any case, before starting work, it is better to carefully study the installation issues, as well as everything related to the characteristics of the material:

- Its pros and cons.

- Correct painting and gluing technique.

- How to glue and with what glue.

- Installation of painting fiberglass on walls and ceilings.

We hope that after reading our information material you have a better idea of how to carry out all such work. We wish you a successful renovation!

How to glue glass wallpaper

Installing fiberglass is not much different from gluing regular wallpaper. It is worth paying attention to precise markings and high-quality joints. How to glue glass wallpaper for painting:

- Before starting work, all skin is protected. It is necessary to prepare construction clothing that covers your arms and legs.

- Gluing of glass wallpaper is carried out in a room with closed doors and windows. Due to a draft, the strength of the fastening is reduced significantly.

- The recommended temperature for working with fiberglass is from +17 to +24.

- Each canvas is measured separately, since the height of the walls within the room can vary. An allowance of 10 cm is added to the required length. Do not forget about adjusting the pattern; the allowance will allow you to make it even, while avoiding the lack of a stripe at the top or bottom.

- Fiberglass is cut with sharp scissors, this is much more convenient. A knife can cause the wallpaper to crumble greatly.

- Do not confuse the front and back sides. The first is usually directed inside the roll. The reverse has a smooth structure and is marked with a gray or blue line.

- You should start from the window or door.

- First, glue is applied to a section of the wall. The surface is completely covered with it, without gaps.

- To glue glass wallpaper efficiently, you need to monitor the location of the trellises. For your own confidence, it is recommended to line the walls with vertical guidelines.

- The glued canvas is leveled with a plastic spatula.

- Excess is removed with a metal spatula and a sharp utility knife.

- The next layer of wallpaper is attached in the same way. The joints are made without overlap or gaps, as smooth as possible.

- Painting is allowed only after the glass wallpaper has dried. This takes on average 1-2 days.

Technical characteristics and features of use

Fiberglass canvas for painting is made from quartz sand, the density varies in the range of 25 – 50 g/m². There are three types of fiber. The first is used for gluing to the ceiling. It has a density of 25 g/m², the thin, lightweight material fits well on the surface and requires a small amount of paint for coating. The base should not have large cracks or irregularities.

The canvas with a density of 40 g/m² is quite durable. It is glued to surfaces subject to significant mechanical stress, vibration, and dilapidated plaster ceilings. This option is considered universal and the most frequently used.

The densest and heaviest is the spider web, weighing 50 grams per m². It is used to cover surfaces with significant damage, and to finish structures in places exposed to large mechanical loads - walls of production workshops, garages, repair shops.

Glue for fiberglassSource sdelai-lestnicu.ru

Well-known manufacturers of painting fiberglass

In order to decide which fiberglass is best for painting walls, you should get acquainted with the products of well-known manufacturers on the construction market. The products of the Swedish company Oscar are of high quality and durability. The price of a roll 50 m long and 1 m wide is about 1200-1300 rubles. Painting webs from Wellton, Pufas, Bostik are no less in demand. Depending on the thickness of the fiber, the cost of a roll is 800-1500 rubles.

Samtex fiberglass reinforcement is considered the cheapest and highest quality; it can be used to repair small cracks in the ceiling and walls. Fiberglass is glued to the surface with glue of a similar brand, then covered with acrylic paints or wallpaper. Spider web with a density of 25 g/m² costs no more than 800 rubles per roll.

Painting fiberglass is sold in such rolls Source redmaster.by

How to glue fiberglass to a surface

Fiberglass for painting is applied using a simple technology, but it is important to take precautions. You cannot work without a protective uniform that protects your nose, mouth, eyes, face and hands from small glassy particles.

It is recommended to reinforce walls indoors, eliminating drafts and rising currents from heat sources. It is advisable to start gluing the panels from a remote corner or hard-to-reach places. It is recommended to apply a deep penetration primer over the putty.

The sequence of applying fiberglass to walls for painting:

- Level the surface (walls, ceiling) with putty, seal seams and defects.

- Prepare a clean surface on the floor where the sheets are carefully cut.

- Measure the required fragment according to the height of the wall with a small allowance (up to 10 cm).

- Treat the surface with glue slightly wider than the canvas.

- Straighten the piece, pressing it against the wall (ceiling) with a roller or spatula.

- Glue the canvas by pressing it with a roller or spatula.

- Continue gluing, lubricating the adjacent part of the wall, laying the panels slightly overlapping. The direction of the fibers is one way.

- Using scissors and a knife, cut off excess pieces and make holes. The final layer of glue achieves uniformity, especially at the seams.

- It is not recommended to ventilate the room until the surface is completely dry. Remove trimmings with a construction vacuum cleaner, wash the floor, and dispose of rags.

More information about the material

The main function performed by Gossamer fiberglass is the preparation and leveling of damaged or imperfectly flat working surfaces of walls, partitions, ceilings, etc. for their further finishing. This material is made from fiberglass, which is where its name comes from. Depending on the density, it is more or less durable.

On a note! If you need to putty fiberglass, keep in mind that the optimal tool for such work is a wide finishing spatula.

The need to use this fiberglass material is also announced by the fact that there is simply no guarantee that plasterboard joints will not develop cracks over time. Even in cases where you use high-quality building mixtures, small cracks and other mechanical damage of a similar nature may form at the joints of plasterboard sheets over time. A thin enough serpyanka does not always prevent their formation. Therefore, the best way to guarantee the absence of cracks in the future is to exclusively use fiberglass web.

Main advantages

Let's briefly list the main advantages that are characteristic of this material. So, here is their list:

- It is completely safe for the health of people who live in an apartment or house.

- High resistance to external influences and density guarantee a long service life.

- It does not accumulate static electricity.

- The ease of installation allows you to glue the web without having any special skills in the construction industry. In fact, this type of work is somewhat reminiscent of wallpapering.

What glue is better to use

As a rule, professionals recommend using a special glue designed specifically for gluing fiberglass. Today there is a fairly wide selection of such solutions on the market. Alternatively, you can prepare your own adhesive mixture for gluing. It’s not that difficult to do this, since the technology for preparing it yourself is quite simple. The basis of such a mixture is the well-known PVA glue, which, unlike starch, is known for its high level of reliability and durability of gluing. By the way, glue for fiberglass sheets can be produced in two types:

- Dry mixture to be prepared.

- Ready-to-use mass.

Warning! Do not stick fiberglass paint directly onto the plastered surface. Due to the fact that these materials have different densities, “bubbles” may form on the web after gluing. Moreover, they can appear even in cases where the work was performed by an experienced craftsman. What then can we say about those who have no experience in the construction industry and for the first time decided to start renovating their apartment.

Now about the glue consumption. The average consumption is 100g/10m2. Given this characteristic, you can use it rationally without applying the mixture excessively. In addition, one of its features is the almost complete absence of stains after drying. Don’t forget about the simple preparation procedure: if you follow the instructions correctly, almost anyone can prepare glue for cobwebs.

The main advantages of the web

We list the main advantages that are characteristic of this adhesive:

- Environmentally friendly and completely safe for human health.

- High level of frost resistance.

- The gluing process occurs over a period of half a day to two days.

How to paint

Once the surface is prepared, you can begin painting.

To prevent it from causing trouble, it is important to choose the right coloring composition, of which there are many types today

You can choose paint:

- water-based;

- acrylic;

- silicone;

- latex.

A distinctive feature of this type of painting is the need to apply several layers. You cannot apply two layers at once: it will warp or peel off in layers in a fairly short time, exposing the base with putty. Failure to comply with the technology for using paint compositions can reduce the service life of the paint. However, it is unlikely that you will be able to paint such a surface several times.

To ensure high-quality paint application, it is important to choose the right tool. The brush in this case is only suitable for painting joints and corners

Using a roller will be more appropriate. It will speed up the painting time and allow you to apply a thin layer, which will reduce the consumption of the coloring composition.

Dip the roller into a container of paint, squeeze it out a little and roll it across the plane. Do not use a tool with a foam rubber coat: the foam rubber will crumble into pieces. We need an analogue with pile. The movements should be in different directions: this will allow the paint to lie better and more evenly. Do not forget that the surfaces must be puttied and primed before painting. When painting, you can apply two or three layers of the composition.

To ensure that the surface preparation for painting using fiberglass is of high quality, let us turn to the recommendations of professionals in the field of construction and finishing.

- After you have glued the web to the surface, strengthen its fixation. To do this, dilute the glue to a liquid consistency and spread on top. It should saturate the fiberglass.

- Do not ignore starting work if it is really necessary. If you do not have enough experience, you can invite a specialist to help prepare the foundation.

- Do the work efficiently and without haste. The strength and reliability of the entire base will depend on how firmly you glue the fiberglass.

- As an adhesive, you can use the glue that is used to glue glass wallpaper. Such mixtures contain special inclusions that prevent the formation of fungus. If you are in doubt about your choice, ask the seller: not every wallpaper glue is appropriate here.

Before painting the walls need to be prepared. The surface must be perfectly flat; even small cracks after applying paint will spoil the appearance and the repair will have to be redone. Putty at the joints and in the corners is applied to a special serpyanka, but this is not always enough. Over time, cracks appear on the walls, the paint falls off along with the putty. This will not happen if you cover the walls with fiberglass material. The work is painstaking, but it can save you time and money in the future. Our experts will tell you how to do putty using fiberglass with your own hands.

Choosing glue for painting web

Fiberglass is glued to a special glue for glass wallpaper. The following brands of adhesives are most popular among professional finishers:

OSCAR is a universal acrylic-based dispersion adhesive. Designed for gluing fiberglass painting canvas and glass wallpaper for painting on various surfaces (concrete, brick, plasterboard, OSB, etc.).

Oscar glue for fiberglass web is available in the form of a ready-made solution, as well as in the form of a dry powder.

The adhesive contains an antiseptic additive that prevents the formation of mold in rooms with high humidity. The glue is applied directly to the surface to be glued, which facilitates the work process; the high elasticity of the composition allows you to adjust the position of the canvas.

BOSTIK 70 is a modern adhesive based on water dispersion (PVA) and starch. Designed specifically for gluing cobwebs, glass wallpaper and fiberglass.

Suitable only for dry rooms. Works great on both absorbent (plasterboard, chipboard, concrete, brick and plaster walls) and painted surfaces. Bostik glue for spider webs is sold ready-made, in plastic 15-liter buckets.

Nortex is a universal adhesive based on modified starch with the addition of an antifungal component. Available in dry and ready-to-use form, suitable for all types of glass wallpaper (fiberglass).

When Nortex dries, it becomes colorless and does not leave stains. The sticker of the thick “cobweb” is done immediately after applying the adhesive to the wall.

Step-by-step instructions - how to glue cobwebs to the ceiling and walls

Painting fiberglass is an affordable and most effective material for combating cracks on walls and ceilings.

It perfectly masks the joints of GVL and KGL sheets, making the surface monolithic and more durable.

To complete the work you will need the following materials and tools:

- primer (you can use ready-made glue for fiberglass);

- roller for applying glue to the wall;

- a clean, dry cloth to remove excess glue;

- plastic spatula for leveling wallpaper;

- a construction knife with replaceable blades and a wide metal spatula for cutting wallpaper;

- ladder;

- respirator (to prevent fiberglass particles from entering the lungs)

Working with a “cobweb” is no different in complexity from the process of gluing ordinary wallpaper without adjustment and takes place in several stages:

Surface preparation. First you need to clean the wall/ceiling of dirt and peeling plaster, fill large flaws, if any, and prime the surface with a latex primer or a weak solution of glass wallpaper adhesive.

Applying glue. Using a fleecy roller or wide brush, apply the adhesive to the wall or ceiling (approximately one glass of glue per 1 square meter of wall). It is advisable to apply the glue to the surface to be treated with the expectation of 2-3 strips of canvas.

A web of “cobwebs” is applied to a wall/ceiling evenly covered with glue and spread evenly so that there are no folds or bubbles. It is convenient to expel air from under the wallpaper using a wide plastic spatula, moving in a herringbone pattern (from the middle to the edges). Then the second strip of fiberglass is glued end-to-end with the previous one in a similar manner.

Which side should you glue the web on? Indeed, fiberglass has two sides, the back and the front. You need to glue the wrong side - the one that has a more fleecy structure.

Second method: Unfortunately, it is not always possible to join two fiberglass canvases perfectly evenly, especially when the edges of the canvas are damaged.

In this case, the web is glued in a different way - overlapping, followed by cutting two sheets with a construction knife.

To achieve an ideal joint in the center of the resulting overlap, cut both layers with a sharp knife and carefully remove the cut strips of both sheets.

VIDEO REVIEW

Pasting fiberglass walls and ceilings

Fiberglass can be glued to any surface . With its help, you can increase the strength of putty and plaster and prevent the formation of cracks. It is used before painting.

Surface preparation

Before you begin work, the walls and ceiling must be puttied with a finish. This will help avoid unevenness and cracks, and will have a positive effect on the finishing result. Before gluing the material, the entire surface is treated with a primer.

Only after this can you proceed directly to pasting.

Master class on how to glue cobwebs to the ceiling

First you need to dilute the glue, which is sold in the form of a dry mixture. The gluing itself is carried out in several stages:

- Pre-cut several pieces of fiberglass. It is better to cut a larger size so that there is enough left for joining the parts.

- The glue is applied to the material itself and on the sides, as well as on the ceiling.

- After gluing the canvas, use a roller to remove the bubbles. This is done from the middle to the edges.

- After the original color of the web has become darker, you can glue the next canvas.

- It is glued to the previous canvas, after which all excess is removed with a knife. This area is then treated with a spatula so that the seams are invisible. And this is done with all previous canvases.

After completing the work, the room should be closed so that the glue dries faster. Also, sunlight should not reach there.

Application for wallpaper: how to glue correctly

Gluing fiberglass under wallpaper is practically no different from any other type of finish. Before starting work you must:

- Remove old finishes and clean walls.

- Remove screws, nails, etc.

- Putty the walls, paying attention to cracks and chips.

- Use sandpaper to smooth the surface.

- Prime the walls.

Further actions are similar to the previous ones.

Fiberglass and finishing

The fiberglass sheets are allowed to dry for a day. After this they move on to putty. Sometimes this stage is skipped: the walls or ceilings are painted right away. In this case, the painted surface will have an interesting “web-like structure”.

If the owners do not set such a goal, then leveling with finishing putty is mandatory. It is recommended to apply two thin layers - from 1.5 to 2 mm. Each of them must dry for 12 hours. Then the surfaces are sanded and primed, ensuring a reliable base and better adhesion, which means less material consumption.

The last stage is painting or wallpapering. In the second case, putty is also required, since heavy materials - vinyl, non-woven - do not really like such a surface. They don't stick well to it. The second reason is overuse of wallpaper glue due to high moisture absorption by reinforced substrates.

Painting the surface after puttying

The main reason that painting of fiberglass web is carried out only after puttying work is carried out is the need to smooth out irregularities - fibers and joints between glued sheets. Unfilled joints become especially noticeable after painting. As a result of using putty, the surface will become smoother, and defects will disappear only with very careful work. Moreover, painting walls or ceilings after leveling with putty is much easier and faster.

It is important to take into account that when painting fiberglass without putty, you will need many times more paint, since strong absorption occurs, and you should not hope that the paint will mask the joints. The main way to paint fiberglass consists of several stages:

The main way to paint fiberglass consists of several stages:

- After the canvases glued to the walls have dried, a primer is applied to them.

- On top of the dried (usually it takes from 1 to 6 hours) primer layer, putty should be applied along each joint. Layer thickness – no more than 1 mm. The result is low material consumption, a fairly smooth surface, and minimal drying time (about half an hour).

- When the layer of putty has dried (a finishing compound is used to finish fiberglass), the entire surface of the wall or ceiling is treated.

- Having reached the required number of layers and making sure that there are no uneven spots, crevices or cracks left on the puttied area, use sandpaper or silicon mesh for cleaning. Then they carry out the final primer and begin painting the fiberglass on the walls.

The process of painting canvas is no different from painting most other materials. To do this, use acrylic, silicone and latex paints, and rollers, sprayers and brushes as tools. To obtain the maximum quality of the coating, it is advisable to paint the fiberglass in 2-4 layers and additionally brush hard-to-reach areas.

Fiberglass sticker

Before deciding whether it is possible to paint fiberglass and putty it before or not, the material needs to be glued to the wall. In this case, the surface to be glued needs to be prepared - leveled using putty, leaving cracks no more than 1 mm thick. You can refuse leveling only in cases where the wall is already quite smooth and strong.

Video: Preparing walls for painting. Fiberglass, putty.

The main nuances that arise during the preparatory work:

- wide cracks are sealed using a special compound for seams or regular putty, but in several steps;

- when using plasterboard sheets, the joints between them must be puttied and reinforced with self-adhesive fiberglass mesh (“serpyanka”); In order for the already pasted wall to be as smooth as possible, it is desirable that the seams between the drywall and the fiberglass sheets do not coincide with each other, otherwise cracks may appear in these places;

- dried “patches” on the wall need to be leveled using putty and sanded until the surface is almost perfectly flat;

- Before the fiberglass web for painting is glued to the wall, it should be cleaned of dust and thoroughly primed.

Due to the fact that the fiberglass gluing is done overlapping, when determining its area, you should take as the calculated value not only the surface of the walls, but also a small margin (at the level of 5–10%). And as an adhesive, it is advisable to use not ready-made, but dry glue, the characteristics of which are the same, and the price is much lower. During the work, special clothing is used - pants, long-sleeved shirts, gloves, a respirator and a hat. All this will help prevent fiberglass particles from getting on the skin and into the respiratory tract.

Other nuances that are taken into account when sticking include the correct laying of the canvas. Fiberglass sheets have a smoother front side - as a rule, it is located on the outside of the roll. It is she who should look inside the room, while the outside one should be applied to the wall or ceiling. You should also place the canvases so that the pile on them is directed in one direction. Otherwise, the paint applied to the material will have different shades.

The main stages of gluing fiberglass for painting are as follows:

- The roll is rolled out and cut into sheets of the required size, which is selected for the walls taking into account a slight overlap. For the ceiling, it is recommended to choose canvases up to 1.5 m long, which are easier to attach to a vertical surface.

- Glue (prepared according to instructions or ready-made) is applied in a thick layer to the surface, starting from the corner of the room. The width of the strip should be slightly larger than the size of the fiberglass itself, that is, about 1 m.

- The first sheet of canvas is glued close to the corner of the room, pressed with your hands and smoothed using a wallpaper spatula along the entire length from the middle of the canvas to the edges.

- The excess part of the fiberglass is trimmed with a knife along a ruler.

- The canvas, already glued to the surface, is coated with glue until the material is completely saturated. You can determine that the canvas has been completely coated by its color, which should become uniform by the end of the procedure.

The remaining sheets are laid in the same way, but with a slight overlap on the previous ones. After gluing and alignment, both panels are trimmed along the joint using a ruler. The cut parts are removed, and the resulting smooth seam is once again smeared with glue and pressed with a wallpaper spatula. When gluing corners, they try to get an even joint before cutting - the corner cloth tears more often than others, and a perfect cut will help avoid tears and cracks.

After the room has been completely covered with fiberglass, it is left closed until the glue dries completely. Usually this period lasts at least a day. At this time, drafts should not be allowed to appear in the room, otherwise air movement will lead to the material falling behind and the need for gluing it or even re-gluing it.

The procedure for gluing fiberglass

How to cover a sports boat with fiberglass?

The use of fiberglass is very common in sports tourism. This type of material is used for covering the hulls of sports boats made of wood or plywood. This allows the vessels to be waterproof and increase their durability.

Fiberglass can be used to protect steel and duralumin cases from corrosion.

Scheme of manual roller forming.

If fiberglass is glued incorrectly, even in ship production conditions, it can peel off. This defect can be noticed when operating sports boats. The selection of incompatible brands of glue and fiberglass can cause serious mistakes along with violation of the temperature and humidity conditions or poor cleaning of the body.

All recommendations must be carefully followed. Different types of fiberglass have different properties. Fiberglass fabric can be used as a reinforcing material for fiberglass structures. Another type of fiberglass is used for electrical or waterproofing of pipelines underground. These 2 types of fabrics have different properties, since the latter type is impregnated with synthetic resin, which is the cause of errors when choosing glue.

Fiberglass can be glued with a special compound that is used when carrying out internal construction work. This type of glue can be used not only for fiberglass, but also when it is necessary to carry out internal construction work or paste a room with glass wallpaper. You can easily create any interior that you have been dreaming of for a long time. Among the advantages of fiberglass adhesive are its uniform texture, high adhesive ability, and ease of use.

How to prepare the surface of a wooden boat and cover its hull correctly?

Fiberglass manufacturing technology.

First, all sharp corners and edges are rounded, the fasteners are masked by recessing, and all the recesses for them are puttied. If the surface is uneven and rough, then it is planed. If there are small splits in the edges, they are cleaned by cutting them using a sharp chisel or knife.

If the surface consists of rotten wood, then it is removed in separate places, otherwise the fiberglass will peel off. After cleaning, the outer surface is coated with heated drying oil so that the wood cannot absorb a lot of water and the fiberglass adheres better.

You should wipe the body with gasoline or white spirit 2-3 hours before covering the body with fiberglass. This will remove dust and degrease the surface. Even the slightest trace of grease can impair adhesion, especially when using epoxy adhesive.

The hull is covered from top to bottom, starting from the waterline to the keel. When hitting floating objects, the edges below will not lift. After laying on the glue-treated surface, the molten fiberglass fabric is smoothed using a roller or a special trowel, removing air in the bubbles and bringing the glue out. Thus, the smooth surface achieved will eliminate the need to putty it before painting.

Advantages and disadvantages of cobwebs

Fiberglass is not without strengths and weaknesses in the same way as other colleague materials. Traditionally, people talk about the benefits first, so let’s move straight to their impressive list. Cobweb:

- it is considered environmentally friendly, absolutely safe, since it does not contain any harmful or suspicious components;

- sometimes it makes it possible to get by with only the starting putty, without the participation of the finishing type of this coating;

- is not noticed in the accumulation of static electricity, so dust ignores it;

- not afraid of high temperatures, temperature changes, or high humidity;

- durable, it is not afraid of mechanical stress, fire, corrosion;

- makes it possible to carry out work indoors and outdoors;

- it is vapor permeable, which means that mold does not threaten surfaces;

- and the adhesive composition for it do not provoke allergies;

- has no sharp unpleasant odors;

- does not require serious care.

The material can be safely glued to any surface - wood, concrete, brick, plasterboard, ceilings or walls.

There are also disadvantages, these include:

- The ability to “attack” low-quality, inexpensive material with a short service life. Such products will disappoint due to the inconvenience of working with them, inelasticity, and fragility.

- Impossibility of using first grade fiberglass in premises. It contains phenols and formaldehyde resins, which are undesirable components.

- The ineffectiveness of the material if there is a need to hide serious defects - large cracks, chips, potholes. They will have to be sealed in advance.

- The need for protection (gloves, glasses, masks, or better yet, a respirator) when working due to small glass particles.

- Difficult to dismantle the coating.

- High consumption of glue.

One cannot but agree that the disadvantages are still relative, since most of them relate to low-quality products. Therefore, in the “battle” of advantages and disadvantages, the first ones emerge as winners.

Fiberglass: application in interior decoration and more...

To save effort during the next repair on leveling the surface of a ceiling or walls with numerous small flaws, you can simply use fiberglass, the use of which is increasingly important when finishing and strengthening internal surfaces.

What is fiberglass?

Painting fiberglass is a modern environmentally friendly material made from mineral fiberglass and organic resins. This is a continuous non-woven fabric without a pronounced pattern, which has enormous tensile strength. Painting fiberglass has fibers that are not intertwined, like glass wallpaper, but are simply glued together randomly, representing a homogeneous web of fiberglass threads located randomly.

Fiberglass, the price of which is quite reasonable, is often called fiberglass. And among the people, such a building material acquired the name “cobweb”, thanks to its pleasant and soft texture.

This building material is divided into several classes, according to its density (thickness). Now you can buy fiberglass with a density from 25 to 65 g/m2. Its density directly affects the cost: the thicker the canvas, the more expensive it is. Experts recommend choosing fiberglass for the ceiling with a density of about 25 g/m2 to guarantee a reliable and lightweight coating. But a material with a higher density is able to withstand more severe mechanical loads, inhibiting the appearance of cracks.

It is wrong to assume that cobwebs and glass wallpaper are the same material. Fiberglass wallpaper is a decorative roll covering made from fiberglass using the weaving method. And fiberglass is a special material for wall coverings, created by pressing glass fiber threads. Painting fiberglass canvas has a thinner, smoother surface than glass wallpaper. The web has no pattern, which makes it possible to color it an infinite number of times. Fiberglass, the price of which is at least 2 times less than the cost of glass wallpaper, is a 100% environmentally friendly material.

Among repair and finishing materials, repair interlining, which does not require puttying and can be applied with almost any paint, deserves well-deserved respect.

Fiberglass web: price, properties, advantages

If you buy the building material fiberglass, the repairman is guaranteed to receive an environmentally friendly finishing and reinforcing fabric approved for use in residential premises.

Products from such manufacturers as Wellton (Finland), Spectrum (Holland, China), Oscar (Russia), Samtex (Sweden), etc. are very popular. Ordinary fiberglass for painting, the price of which ranges from 500 rubles. up to 800 rub. for 1 roll (25 m2 or 50 m2) depending on the manufacturing company, most often it has a width of 1 m.

Finnish fiberglass Wellton has proven itself excellent among our compatriots:

- features increased fire safety

- has heat, water and acid resistance

- hypoallergenic, durable

- Excellent leveling and finishing

- allows finishing work to be carried out in rooms with high traffic volumes due to high density

Modern oscar fiberglass made in Russia-Sweden is a fairly wear-resistant, strong material. It is almost impossible to damage the glued panel unless you cut it with some sharp object. Oscar fiberglass is a relatively inexpensive material that can be painted with any type of paint with a consumption much less than when painting only a puttied surface. VVG, Oscar, Velton fiberglass can be re-painted.

Advantages and disadvantages

Fiberglass has the following advantages:

Resistance to temperature fluctuations. It is permissible to prepare walls for coating at temperatures from -40 to +60 degrees. Air permeability and hygiene. The use of the material helps to avoid the formation of condensation and the proliferation of fungal microorganisms. No risk of electrification. The material is considered antistatic. Therefore, dust does not accumulate on it. No negative impact on people's health. This is due to the environmentally friendly properties of the coating. Hypoallergenic properties

This is very important for people who are prone to allergies. Fire resistance. This is one of the most important advantages. Affordable price

This helps to make quality repairs and reduce costs. High wear resistance. The material does not deteriorate for a long time. Possibility of coloring. This makes it possible to apply paint many times. It is also possible to apply wallpaper from different materials to the coating - non-woven fabric, vinyl, paper.

However, the material also has some disadvantages. You need to work with it very carefully. This is due to the risk of small fragments breaking off from the surface. They can penetrate into the skin, which can cause great harm to health. In addition, there is a risk of fragments getting into the eyes or respiratory organs.

How to putty spider webs correctly?

To putty fiberglass, it is better to use non-shrinking gypsum or fine polymer putty (acrylic, latex, silicate)

It is important not to use coarse putties. Below we discuss the features of puttying on the ceiling and for painting.

On the ceiling

Tip To cover the cobwebs, you will need to apply at least 3 layers of putty with a break for drying.

The material is attached to the ceiling using putty tape or mounting adhesive. If you fix the canvas with a stapler, it may sag. Puttying under wallpaper, panel, clapboard or tile cladding is allowed without leveling significant defects and imparting a white tone.

Technology:

- mix the solution according to the instructions until the lumps and paste-like consistency are eliminated;

- Using a wide spatula, moving from the outer corner of the ceiling, apply a layer of putty in semicircular movements;

- do not throw the solution on, but smooth it over the surface, moving from the corners to the middle of the plane;

- after application, cut off the composition with vertical and horizontal movements, removing excess solution;

- Having treated the ceiling with the first layer, without waiting for it to dry, begin installing fragments of fiberglass;

- wait for the solution to dry (up to 8 hours), apply at least 2 more layers with a break for drying.

If the surface is being prepared for painting or plastering, sand the ceiling using a trowel with a P180 attachment in a circular motion. Then dust the base with a vacuum cleaner, do not use a damp cloth. When preparing the ceiling for wallpaper and cladding, this stage can be neglected. Before decorative cladding, apply a layer of penetrating primer.

For painting

The base for painting is puttied using the same technology. However, the process differs in a number of ways regarding materials, coating and defect handling. These include:

- the need to create a flat and monotonous surface;

- mandatory sanding of the final layer of putty;

- applying at least 4 layers of putty to cover the cobwebs;

- use white acrylic putty;

- use a covering snow-white primer on the finish.

Here it is important to achieve a perfectly smooth surface by sanding and multi-layer coating. Each layer is applied 1 mm thick

The total thickness of the coating cannot exceed 10 mm. If the solution gives a yellowish or grayish tint, use a white covering primer.

Advice: On the final layer, it is allowed to add color to the putty to match the finish. Only polymer compounds can be tinted in bulk. For ready-made solutions, use liquid pigment; for mixtures, use dry pigment.

How to prepare fiberglass for painting

Craftsmen are often interested in questions: is it necessary to prime fiberglass, and is it necessary to putty fiberglass and why is this done? There is no need to prime the coating before puttying or painting, because the walls have already been primed before gluing it on. In addition, the glue acts as a primer.

The question of whether puttying is necessary does not have a clear answer. Fiberglass has a beautiful texture, which is sometimes preferable to preserve, but the paint consumption will be very high and at least 4-5 layers will be required. Paint will make the joints noticeable: even if they are made perfectly, their mere presence will not at all decorate the room. It is better to putty fiberglass before painting for another reason: small fibers can get into the air, which is harmful to health, and putty completely prevents their penetration.

What to putty on? There is no special putty for fiberglass; you can use any finishing mixture based on gypsum or polymer, as long as it is of good quality.

How to putty painting fiberglass? The technology has some features:

- by the time the putty is applied, the glue must be completely dry;

- if the coating was pasted several days ago, it needs to be cleaned of dust;

- the adjacent surface is protected with masking tape;

- putty is applied in two layers with an interval of 24 hours;

- the thickness of the first layer should not exceed 2 mm;

- the second layer should be just as thin and completely cover the first;

- After drying, the putty is sanded using a block of sandpaper with a grain size of no more than P150.

Fiberglass putty allows you to get a perfectly flat, durable surface.