Waterproofing work is often carried out using a bitumen primer. To know exactly how much material you will need to purchase, you need to make calculations in advance. Manufacturers indicate the average consumption on the packaging of their products, but there are factors that can change the amount spent. How to correctly calculate the primer consumption per 1 m2 of waterproofing will be discussed below.

general description

The primer is made from bitumen to soften petroleum bitumen, it is subjected to high temperature treatment, and organic solutions are used. The composition cannot contain other elements, toxic diluents are not used. Carrying out waterproofing on the roof will be easier if you first apply a bitumen primer to the base, the quality of the work will be better.

To soften petroleum bitumen, it is subjected to high-temperature treatment and organic solutions are used.

Bitumen composition without organic solvents

Bitumen solution No. 4 does not contain organic solvents. The product is presented as an aqueous emulsion with technological additives. The technical specifications are as follows:

- the proportion of non-volatile substances in relation to the total volume is 25-40%;

- It takes 60 minutes to dry completely;

- when exposed to more than 75 degrees Celsius, the film begins to soften;

- conditional viscosity is 5-30 units;

- the operating temperature range is from +5 to +30 degrees Celsius.

The soil is used only inside the building. Concrete structures made of cement with sand and foam blocks are subject to treatment before installing a waterproofing coating. Consumption of bitumen primer TechnoNIKOL No. 4 per 1 sq.m. is 0.25-0.35 liters.

TechnoNIKOL bitumen solution No. 4 Source www.tn.ruTypes of bitumen primer

To find out what primer bitumen consumption will be per 1 m2, you should first study the varieties presented on the construction market. There are concentrated types and ready-made options on the market.

The first type requires dilution of the composition before use with an organic diluent. You can choose gasoline, white-spirit or kerosene for this purpose. The dilution proportion should be 1 to 2. This option is convenient when you need to save space during transportation, as well as for storage if work will not be carried out for a long time.

The ready-made primer can be used immediately; there is no need to bother diluting it. You just need to mix the composition well before applying it to the material. This saves time and makes the process more comfortable.

The ready-made primer can be used immediately; there is no need to bother diluting it.

Safety precautions

Bitumen-polymer soil is a flammable substance, so during work, storage and transportation it is necessary to observe safety precautions:

- Do not work near open flames;

- Be sure to use protective clothing, gloves and goggles;

- When working indoors, a supply of fresh air should be provided or ventilation should be built in;

- Storage and transportation must be carried out strictly in metal containers, which must be hermetically sealed.

Application area

When a decision is made to carry out waterproofing work with this type of product, then knowing how much product will be needed for the process is mandatory. Then the repairs will be carried out at one time without the distraction of purchasing the missing quantity.

The average consumption rate is 0.25-0.35 kilograms per square meter. It is influenced by the level of adhesion of the base and its evenness; the presence of a rough structure will increase consumption.

Bitumen primer can be used on various types of coatings: asbestos-cement, concrete, metal, reinforced concrete, wood and porous. The product can also be used for roofing and waterproofing. For the latter type of repair, the solution can be used as an independent product, or in combination with other waterproofing agents.

There is a demand for the use of materials with a bitumen base as a waterproofing agent on foundations, underground structures, metal pipelines and steel pipes. It has the property of anti-corrosion protection of metal, so it is also used for this purpose.

The product can be used for roofing and waterproofing.

We prime the foundation with primer correctly

Before applying coating waterproofing or gluing roll materials, it is necessary to perform a number of preparatory operations and apply a bitumen foundation primer to the entire area of the base. The general scheme of work is as follows:

- First of all, it is necessary to ensure an approach to the work site. To do this, the soil is removed from the foundation at a distance of at least a meter.

- Next, the concrete base must be allowed to dry completely. This is especially true if the foundation was not covered with waterproofing materials in a timely manner.

- The next stage is cleaning the foundation surface from loose concrete particles, soil residues and other debris. For this purpose, various brushes with both metal and synthetic bristles are used.

- After all the preparatory work has been completed, the foundation is directly waterproofed with a primer. To do this, the composition is applied in the manner indicated above, trying to cover the entire surface of the base of the house or bathhouse without gaps. Many of today's bituminous primers have a very short drying time. This allows you to apply three or four layers of primer during daylight hours, with each layer completely drying.

- After the last layer has completely dried, which is checked by touching it for tack, you can apply the previously selected type of foundation waterproofing.

Primer application

How to calculate the required quantity

The ability to calculate bitumen primer consumption will help you prepare the required amount of product at once. The average indicators are prescribed on the packaging of a particular product, and this figure serves as a guide. However, it may become larger if the application is carried out on a porous surface structure, which will impregnate part of the material, and in order to obtain a smooth surface, more product will need to be applied.

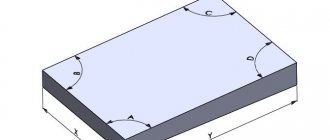

To obtain the number of kilograms of product required for finishing. The first step is to calculate the area of the surface being treated. The result is then divided by the consumption rate.

The average indicators are prescribed on the packaging of a particular product, and this figure serves as a guide.

Rating

You can also find a huge variety of primer compositions on the market.

The most popular of them are the following:

- Bitumen emulsion primer TechnoNIKOL No. 04 is a water-based primer intended for waterproofing work in interior spaces. It has a low viscosity, dries very quickly, and has a neutral odor that does not irritate the olfactory organs. Water-based primer is available in 10 and 20 liter Euro jars. The shelf life when unopened is 6 months. The average price at which bitumen emulsion primer TechnoNIKOL No. 04 is sold in a 20-liter container is 1,100 rubles.

- Bitumen primer AquaMast - made on the basis of petroleum bitumen and organic solvents, used for preparing bases for both roll and coating waterproofing. Dries quickly, has a wide temperature range (from -10 to +40ºС) for application. Available in 3, 10 and 18 liter Euro cans. The shelf life is 18 months. The average price of the most common container with a volume of 18 liters is 1300 rubles.

- Bitumen-polymer primer TECHNONICOL No. 03 is a primer used for preparing bases for waterproofing roofs and treating metal and concrete surfaces of bridge spans. It consists of petroleum bitumen, polymers and additives that improve the adhesion (sticking) of this material to the surface being treated. It has medium viscosity (10-30 sec), complete drying time is no more than 5 hours. Available in 20 liter Euro jars. The shelf life is 12 months. Average price – 2600 rub.

- PAZ PRIMER is a primer consisting of a water emulsion of petroleum bitumen and polymers. Used for preparing porous concrete surfaces. It has a low viscosity, dries quickly, and has no unpleasant odor. Available in 4 and 15 liter plastic cans. Shelf life – 12 months. Average price – 1500 rub. for a 4 liter container.

- Bitumast PRIME waterproofing mastic is a mixture of bitumen, organic solvents, corrosion inhibitors and additives (plasticizers, fillers). Has high penetrating and adhesive ability.

The specific gravity of the primer is 0.83 kg/l. Used for priming concrete, metal and wooden surfaces. Available in 21.5 liter Euro jars with a shelf life of 12 months. The average price for one container of such material is 1,300 rubles.

Prices for bitumen primer AquaMast

Standards of use

The norm for spending money per square meter is 250-350g/m2. However, it is possible to obtain a similar flow rate if you correctly follow the principle of covering the surface with the material. Bitumen is applied to concrete, concrete-cement and other porous, rough substrates.

When you have to work with uneven surfaces, pores and dust, the tool you should choose is a brush or brushes made of nylon material. Their use will allow you to obtain a base well impregnated with bitumen and improve the level of fixation.

Applying a primer solution will result in a longer product life. When the task is to glue materials in rolls onto reinforced concrete or concrete with a primer, the sections of the seams between the blocks must be treated with a primer. Each new layer of rolled material can be glued to the base 4 hours after gluing the previous one.

The materials in rolls are laid in an overlapping manner, the laying width is 10 cm. Care is taken to ensure that cross-gluing does not occur. When the positioning of the web is completed, the surface is rolled with a specialized cylinder-shaped roller.

The materials in rolls are laid overlapping, the laying width is 10 cm.

Bitumen composition with polymers

Technonikol's products for priming surfaces are presented in three options. These are compositions numbered 1, 3 and 4. Thus, the bitumen-polymer mass (No. 3) has the following characteristics:

- the share of non-volatile substances from the total mass averages 27%;

- Complete drying time takes approximately 11 minutes;

- when heated, the polymer film does not soften;

- conditional viscosity is in the range of 10-30 units;

- The operating indicators of the thermometer are indicated in the range from -20 to +40 degrees Celsius.

Bitumen composition TechnoNIKOL No. 3Source uralint.ru

Consumption rates of bitumen primer for different surfaces

Consumption also depends on the type of base that will be processed. This factor is important when calculating the amount of waterproofing agent.

So when working with a concrete surface, you may need from 250 to 350 grams per sq.m. The same indicator will be when finishing slate and a plastered base.

Application to metal and steel will require 200 grams of bitumen primer; wooden structures use 300-350 grams. When old roof coverings made from rolls are processed, there will be more waste, the figure can reach 0.5 kilograms per square meter.

The most wasteful consumption will be when treating roofing with powder - 750-900 grams.

Consumption also depends on the type of base that will be processed.

Areas of application of IKOPAL primers

ICOPAL brand products are widely used in construction and repair work. In construction, bitumen-based primers are used for preliminary preparation of surfaces, which is the first step in the complex of waterproofing works. When applied to a waterproofing base, this composition performs the following functions:

- fills the pores of the material, evens out flaws in porous surfaces;

- strengthens the base, gives it hydrophobic properties;

- improves the adhesion of waterproofing material to the surface being treated.

Bitumen primers of the ICOPAL brand provide the required level of adhesion of the roofing covering to the base (up to 0.5 MPa). This is a mandatory requirement when carrying out work on waterproofing various structures using fused rolled materials.

Due to excellent adhesion to metal, concrete, cement-sand screeds, bitumen-based primers are widely used in various branches of construction. They provide strong adhesion of the fabric of built-up or self-adhesive bitumen material to all types of surfaces, including porous and rough ones.

Using IKOPAL primers, the following is treated before applying waterproofing:

- concrete surfaces of flat roofs, interfloor ceilings;

- walls of basements, cellars, ground floors, underground car parks;

- foundations, other underground structures in contact with the ground;

- spans of bridge structures, viaducts.

Bituminous primers of the ICOPAL brand can be used to treat new concrete bases during the construction of buildings and structures. And also during repairs, reconstruction of existing facilities, when laying or updating roofing and waterproofing coatings.

Bitumen-based primers are universal compositions. Due to their excellent adhesion and hydrophobic properties, they can be used to process various parts/structures that are in contact with the ground or exposed to precipitation and moisture from the air.

The scope of application of the IKOPAL primer is not limited to the treatment of load-bearing structures when carrying out waterproofing work. They are also used to process:

- metal structures, main pipelines;

- recessed bases of wooden, metal poles or supports;

- external surfaces of concrete storage facilities, well rings;

- balconies, verandas, terraces.

Consumption of bitumen primer "TechnoNIKOL"

TechnoNIKOL is a brand that is chosen by many ordinary buyers, as well as professionals. It produces a large number of bitumen compositions that can be used for different situations. For this reason, the consumption of TechnoNIKOL bitumen primer per 1 m2 will be considered.

Often ready-made mixtures are sold with a volume indicated only in liters. So a liter of primer from this company is enough to cover 3.3 meters square. The indicators may be slightly different; this may be affected by the type of material that will be processed.

It will be more convenient to work in hard-to-reach areas using a brush and a nylon brush. For a large area, a roller is selected; it helps to quickly and evenly distribute the bitumen over the surface.

To prepare the surface, it is first cleaned; it is recommended to use a polypropylene broom for this purpose. In order for the coating to last a long period of time and be distributed evenly, it is necessary to eliminate the old finish.

TechnoNIKOL produces a large number of bitumen compositions that can be used for different situations.

Rules for applying bitumen primer

Working with bitumen primers is easy, provided that all the nuances of the production process are followed. The work can be divided into the following stages:

- Preparing the base . The surface intended for treatment is completely cleaned of dust and construction debris.

- Preparation of the composition . It was mentioned above that primers are ready-to-use and highly concentrated. In the first case, the composition is mixed using a construction mixer and applied to the surface. In the second, the composition is diluted with organic solvents, observing the proportions specified by the manufacturer.

- Application . The processing method may vary depending on the type of base and application technology. In most cases, the composition is evenly distributed over the surface using a nylon brush or roller. If we are talking about a large area, the primer is poured and then leveled with rubberized scrapers.

It is more convenient to treat vertical structures with spray guns.

Further work can begin only after the primary insulation has completely dried. If the temperature conditions are observed, the topcoat or additional insulation can be applied after 10-12 hours .

It is important to understand that organic solvents included in the primer require mandatory safety precautions. All work is carried out only in well-ventilated areas, using personal protective equipment.

Calculation of primer consumption per 1 m2

Calculating bitumen consumption is easy; you just need to calculate the area of the base. And also find out the consumption indicator of a specific primer. This information is available on the Internet. The manufacturer’s website also often contains an online calculator, with which calculations are not difficult.

Calculating bitumen consumption is easy; you just need to calculate the area of the base.

Bitumen primer is a reliable product that will help to carry out high-quality waterproofing of various structures. To carry out repair work, craftsmen calculate in advance the number of kilograms that will need to be purchased to cover the entire area. The article described in detail the rules for conducting independent calculations.

Specifications

This material has the following technical characteristics:

- specific gravity of the primer – 0.8 kg/l;

- content of non-volatile components – 30-40%;

- softening temperature – not less than +80ºС;

- conditional viscosity – from 10 to 30 seconds;

- Time for complete drying of the applied layer is 12 hours.

The material is sold in 10 and 20 liter sealed and easy-to-carry metal buckets – Eurocans.

They control the indicators possessed by the bitumen primer, GOST R 52487, as well as GOSTs 19007-73, 8420 and 9070.

Important! Each batch of material sold by a wholesaler or retailer must be accompanied by a passport indicating the characteristics and date of issue.

Building materials cannot be sold without a passport. The seller must provide it upon the buyer's first request, regardless of the quantity of primer purchased. The lack of a document from the seller most often means that he is selling warehouse balances that have expired.

The need for primary processing

Before measuring the consumption of bitumen primer, you need to find out what can be achieved thanks to the presence of such a coating:

- the applied layer increases the adhesive properties when the waterproofing or roof covering comes into contact with the covered area (roof, basement or cellar, basement level, etc.);

- applying TechnoNIKOL bitumen primer to 1 m2 or more is a prerequisite for subsequent operations related to waterproofing;

- the use of primer over the entire treated surface helps to saturate and strengthen the outer layer, which can be a concrete screed, outdated bitumen coatings, modern porous foam concrete blocks or anything else, while the applied primer binds small particles, fills microcracks and crevices, providing strength and monolithic structure;

- Consumption of bitumen primer per 1 m2 of concrete surface ensures moistening of the top treated layer of any structure, which increases the speed of further operations in this area.

The use of primer and mastic ensures maximum quality

Due to the described material with a primer, it is possible to form a high-quality interface between waterproofing materials of all types with porous, fragile or rough surfaces.

The modern market offers a wide variety of primers from popular manufacturers. The products have some differences in the composition of all kinds of organic non-toxic solvents, but the similarity in all lies in the base - bitumen and water, an integral part of the chemical formula.

Popular products

Gone are the days when homemade primers were used to prime the surface. It was then cooked under rather dangerous conditions over an open fire in a metal container, melting bitumen and gasoline. Today, one of the leaders in this field is the TechnoNIKOL brand.

The advantages of a product manufactured using an industrial method are:

- safety of use and ease of operation;

- fairly fast and maximally complete drying of the material at the correct consumption per 1 m2;

- excellent parameters for fluidity, adhesion and uniform distribution, and in many cases you can do without re-processing;

- the material has temperature stability after hardening, since most brands intended for different types of priming have a melting point of +80ºС;

- the primer layer creates a barrier to corrosion and moisture;

- You can work with all kinds of compositions in a wide range of ambient temperatures.

The actual consumption of TechnoNIKOL bitumen primer per 1 m2 depends on the method of its application.

The compositions offered by manufacturers are used for different purposes:

- Roofing brands. Used for treating concrete areas on flat roofs. The product forms an additional barrier to precipitation and ensures adhesion of rolled materials, such as roofing felt, to the concrete base.

- Road stamps. Used for binding crushed stone during asphalt laying.

- When processing metal surfaces (all kinds of metal structures, pipelines), current brands of bitumen primer are also used.

- Universal brands. Often they use compositions intended for unified rather than narrow-profile operations that are suitable for any surface.

VIDEO: review of insulation products from

Comparison of popular TechnoNIKOL primers

Let's look at the most popular bitumen solutions used in our country. They are easy to find in specialized supermarkets or can be ordered online.

TechnoNIKOL No. 01

Primer TechnoNIKOL 01 is made on the basis of petroleum bitumen and organic solvents. The mass has a softening temperature of about 80°C. It also has high penetrating and wetting properties. It is used for priming areas before laying roofing waterproofing insulators that are built-up or with a self-adhesive side.

This primer is consumed per 1 m2 approximately at the rate of 200-350 ml. Accordingly, a liter volume is enough to process about 3.5 m2 of usable area. According to consumer reviews, the complete drying process takes up to 12-14 hours.

Buyers can purchase the composition in one of the following types:

- ready-to-use solution;

- concentrate that must be diluted in the prescribed proportion.

Some kind of solvent is usually added to concentrated formulations, for example gasoline, kerosene or white spirit. One and a half to two parts of liquid are poured into one part of bitumen. The substance is sold in containers of 20 liters.

TechnoNIKOL No. 03

The composition is bitumen-polymer. There are also additives in the form of organic solvents and adhesive components. It is used to treat steel surfaces and bridge structures before laying waterproofing materials.

Operation is allowed at temperatures -20°С…+40°С. If work is expected in conditions below +5°C, it is recommended to keep the containers warm for at least 24 hours. Material consumption per square meter is 0.25-0.3 liters.

Surface treatment volume

The consumption of bitumen per 1 m2 or other composition depends on many factors. Today you can use various types of protection, including:

Wall waterproofing scheme.

- Penetrating, i.e. impregnating waterproofing. It is used for finishing porous surfaces; it contains small particles of cement and sand, and chemically active particles. This composition is used for basements, for foundations, and when it is necessary to repair concrete structures. It will take 800 g with a layer thickness of 1-3 mm. If there are cracks, then the amount increases to 1.1 kg per square m.

- Calmatron is a special type of waterproofing that is used for brick and concrete surfaces. The volume is 1.6-3.2 kg per 1 m², if 2 layers are applied.

- The adhesive protection is applied to vertical and horizontal surfaces and has a high level of protection. The quantity depends on how many layers will be applied and how wide the material is. We must not forget about the overlap, which is 10-15 cm.

- Paint protection is a material that is applied in liquid form to the surface of the structure. After drying, a strong film is formed that prevents moisture from penetrating inside. The quantity depends on what type of material is used. Most often these are bituminous compounds that provide the maximum level of protection. When bitumen is consumed per 1 m2 of waterproofing, it takes approximately 0.8-2.2 kg.

- Coating waterproofing is a mixture based on polymer, bitumen mastics, resins, mineral-cement, polymer-cement plasters. Can only be used for external work. The costs in this case are as follows: 2-3 kg will be required for every 1 m² of area.

- Pure bitumen is not used so often in construction; mixtures based on it remain popular. But it is still used for waterproofing foundations, if necessary, to carry out repair work on roofs. Consumption depends on the thickness of application and whether any additives were used, on average it is 2 kg per 1 m². It also takes into account under what conditions and for what surface it will be applied. For example, for roofs and foundations this indicator will be completely different. We must also remember about the number of dry residues, i.e. the amount of material remaining after drying.

Which to choose?

The most versatile and popular composition is TechnoNIKOL 01. Today it costs about 1,600 rubles for a container of 20 liters (16 kg).

It is ideal in consistency, price and quality. Suitable for poor surfaces, absorbs quickly and provides additional protection against moisture. The roof stays on it for a very long time if it is laid in accordance with GOST.

The cheapest option is the TechnoNIKOL 04 primer. It is fluid and excellent for an even and high-quality screed. But if there are microcracks in the screed, or the surface is uneven, then it is no longer enough. No. 4 is a primer in the full sense of the word, with a minimum of waterproofing properties.

TechnoNIKOL 03 is the highest quality primer that is on sale. It contains polymer substances that create an additional protective barrier. Well suited for rainy areas, foundations, processing concrete in contact with water. But the price is appropriate.

For roof repairs, it is best to choose the 01st primer model. It is the most common, reliable, and easy to work with due to its fluidity, whether on vertical walls or on a horizontal surface.