Plywood is traditionally one of the most popular finishing building materials. This is a multi-layer wood board, which is obtained by gluing veneer sheets with a perpendicular overlay of a new layer relative to the previous one. The popularity of plywood is due to its wide versatility and relatively affordable price. But it also has a big disadvantage - weak natural protection from environmental influences, including water.

To protect plywood sheets from aggressive moisture and other negative influences, various materials and material processing methods are used, including:

- varnish coating;

- impregnation with drying oil;

- fiberglass protection;

- coloring;

- creation of lamination.

We will talk in more detail about the most effective and efficient methods of protecting plywood from external negative influences.

Types of impregnation

In construction retail outlets you can find excellent modern compounds used to impregnate plywood in order to acquire water-resistant characteristics. These include a number of products.

- Drying oil . It has an oily composition that penetrates deeply into the surface of the plywood and forms a water-repellent film.

- Polyvinyl acetate composition . PVA may be present in glue, paints or putty. Impregnation is suitable as a protective layer for preparing plywood sheets under laminate or linoleum. Polyvinyl acetate is not suitable for external protection, since it cannot cope with moisture for a long time.

- Nitro paint . It not only makes the surface of the plywood resistant to water, but also decorates it.

- Nitrolac . Has good water-repellent characteristics. It is applied in several layers after covering the plywood with drying oil.

- Wax . If the plywood area is small, it can be treated with wax. After polishing, it acquires an attractive, immaculately smooth appearance.

What impregnation is better to buy for plywood

Moisture-resistant impregnation for plywood is available in a variety of variations on the market. The composition may contain linseed oil, drying oil and other elements that contribute to obtaining a high-quality result. Mastics are also used, but they differ in the complexity of the work.

It is important to determine whether it is necessary to change the color of the base or whether there is a desire to maintain the original version. Nitro enamels allow you to get any shade from gray to red.

If constant temperature changes are expected, then compositions that can withstand such exposure should be selected. It is better to seek help from a specialist who, taking into account the operating characteristics, will suggest a product that will satisfy all needs.

Nitro enamels allow you to get any shade from gray to red.

We protect plywood from moisture in simple ways

- Types of plywood

- What impregnation is better to use?

- PVA glue

- Drying oil

- Nitrolac

- Fiberglass

- Surface preparation

Standard furniture boards cannot withstand prolonged exposure to moisture. The material begins to delaminate and warp. But the quality of inexpensive construction FSF plywood is not always the best. Facades finished with such slabs darken over time and swell in places. We'll tell you how to treat plywood so that it becomes moisture resistant and can be used in outdoor conditions.

Types of plywood

The moisture resistance of this material depends on the composition and production method. Plywood is a name given to wood boards made using glued veneer (thin layers of wood). Less moisture-resistant birch is used in the production of furniture plywood. Building boards (they are the ones most often used in everyday life) usually consist of 3-5 layers of hardwood, pine and spruce veneer. These types of wood are more resistant to rotting.

But still, the moisture resistance of plywood depends primarily on the type of glue used. Its composition must be indicated in the labeling:

- FBA: casein glues that swell easily in water;

- FC: a mixture of urea and water-resistant formaldehyde resins; materials with such impregnation can only be used indoors;

- FSF: phenol-formaldehydes, adhesives of increased water resistance; the compositions are chemically aggressive and are not recommended for interior decoration of houses and apartments;

- FB, BS and BV: bakelite adhesives and varnishes: additional treatment of plywood from moisture and rotting is not required in this case; wood impregnated with them acquires the highest strength and wear resistance; materials have a special purpose and are used in mechanical engineering, aircraft construction and even the space industry.

Additionally, you can protect FBA, FSF and FC boards from rotting in several ways. Each of them has both advantages and disadvantages.

What impregnation is better to use?

Coating with special compounds will help make plywood moisture-resistant at home:

- PVA glue or epoxy resin;

- drying oil;

- moisture-proofing primer containing an antifungal antiseptic;

- fiberglass;

- nitro compounds.

We recommend: Choosing a sandblasting gun

Which method is more effective? Let's talk about each of them in detail.

PVA glue

Such impregnation for plywood is used only on the condition that the material will be used indoors. After all, PVA glue is not able to withstand moisture for a long time. Its main advantages are low cost and low toxicity. This finish is ideal when laying plywood, for example, under linoleum or laminate.

Epoxy resin can provide good protection even from moisture outdoors. It is undesirable to use it in residential areas due to its high toxicity. Despite the fact that the cost of impregnation is quite high, it is not exposed to sunlight.

A PVA or epoxy solution is applied to both sides of the sheet and ends. Each layer of glue must be thoroughly dried. The treatment is carried out repeatedly until the tree stops absorbing the solution.

Drying oil

Special film-forming compounds based on vegetable oils will help protect plywood from moisture. For impregnation, it is better to use natural, for example, linseed oil. To increase absorption, it should be preheated to 50 degrees. This can be done in a water bath. Please note that although this impregnation method is very effective, it will take a long time to dry the plywood. A hair dryer will help speed up the process.

There should be several layers of drying oil - as many as the tree can absorb. It will take at least 2-3 applications. If the material will be used in a damp room or outdoors, the number of layers must be increased to 3-4.

When using any method of treating plywood from moisture, do not forget to thoroughly coat the ends. You can get maximum protection by simultaneous impregnation with drying oil and nitro varnish. Pre-coating with an antifungal primer will help enhance moisture resistance.

Nitrolac

Before applying it, the surface is pre-treated with drying oil in 1-2 layers. To obtain maximum protection, you will need at least 5-6 thin layers of varnish. Unlike drying oil, it dries quite quickly.

To ensure that the plywood is well saturated, you should not use too thick a composition. The varnish must be diluted thinner. It is better to treat wood with it using a spray bottle or roller.

Fiberglass

The basis for the coating will be the same drying oil. It is necessary to carefully treat the surface in several layers.

Next, apply a layer of varnish. We begin laying the fiberglass fabric after it thickens a little. The material, soaked in turpentine (it will increase adhesion to the surface), should be well straightened and pressed as tightly as possible to the plywood.

To increase moisture resistance, you can coat the plywood with an additional layer of oil paint. Such triple protection will be most effective.

Surface preparation

The wood intended for processing must first be dried and cleaned of grease, dirt and dust. Plywood brought in from the street should be kept indoors for at least 24 hours in a horizontal position. For better ventilation, the sheets are placed at a distance from each other. This can be done using wooden blocks that are laid between the panels.

If the plywood has been previously painted, the paint layer will have to be completely removed. Next, the surface is treated with sandpaper to remove a thin glossy layer. A rough surface will better absorb glue or drying oil. You should not use sandpaper that is too coarse - it will leave burrs.

The choice of impregnation method depends on the installation location of the plywood and the method of operation. When used in residential premises, 2-3 times impregnation with PVA glue is sufficient. If the material is planned to be used in harsh outdoor conditions, it is better to ensure the maximum degree of protection, first treat it with drying oil, and then cover it with varnish and fiberglass.

Subsequent treatment of plywood to maintain moisture protection

Despite all the degrees of protection, over time the surface of the impregnated plywood wears off and cracks. Veneer layers that are poorly glued together can fall apart over time. The attachment points, as well as the ends of the plate, are especially vulnerable. As a result, its moisture resistance decreases. Particular attention is paid to waterproofing such places during installation of the product. Plywood, even treated with special means, should be placed in places protected from moisture. The walls of buildings, roof overhangs, and awnings will prevent direct water from entering the panel.

When the first signs of damage to the coating appear, measures are immediately taken to restore it. You can’t just paint over the cracks, as rotting will continue under a layer of paint. Damaged areas are cleaned with sandpaper. Then the protective layer is reapplied. Such restoration can keep the moisture-resistant coating in working condition for a long time.

It is not at all necessary to buy expensive brands of moisture-resistant plywood. You can do everything yourself. But, before deciding on the impregnation operation, you should analyze all the methods and choose the most suitable one for yourself. If you have difficulty making a choice, you can always consult with specialists.

How to make plywood moisture resistant with your own hands

To impart the desired characteristics, various methods are used, involving the use of special impregnations.

Painting with nitro enamel

This is an effective method that ensures a surface that is resistant even to direct contact with water.

Process diagram:

- All sides of the sheet are sanded using abrasives with a coarse and medium structure.

- The surface is completely covered with drying oil; the ends need to be soaked especially well.

- The paint is diluted to a liquid state and laid evenly on the dry slab. The composition acts as a primer, creating a reliable basis for future work. It is recommended to paint in 2–3 layers. It is taken into account that the last coating should have the smallest thickness.

- As additional protection, fiberglass impregnated with nitro solvents is used. The canvas is glued to the entire area of the panel, but only after the first layer of paint.

Nitroenamel dries completely in a couple of hours, but this paint has a strong and pungent smell of solvent, and it also needs to be applied at least 2-3 times, since the composition is strongly absorbed

We recommend: Selection and rules for applying wood oil

The technology allows the use of similar compositions marked with moisture resistance.

Impregnation with drying oil

This solution is one of the most common and most accessible. At home, the oil is used as an antiseptic and increases the durability of the product. Processing is carried out according to the following algorithm:

- Prepare a suitable container, roller and brushes. The drying oil is mixed well and poured into the container. The composition is heated to a temperature of 60 degrees. Caution is required as the material is flammable.

- All plywood sheets must be treated with the prepared solution. It is important to thoroughly saturate each area, paying special attention to the edges.

- The surface is forced to dry. To do this, it is advisable to use a hair dryer with power adjustment.

- The drying oil is heated and the entire processing cycle is repeated. The mixture must be applied until it stops being absorbed.

Natural types of drying oil have a high price, so most often plywood is treated with semi-natural compounds called oxols

The resulting coating not only is resistant to dampness, but also destroys mold and mildew.

Attention! The base is suitable for varnishing and painting with compositions that contain drying oil used for processing.

Coating with PVA glue

This impregnation for plywood is recommended for use when additional protection against rotting is necessary, which is especially important for floor coverings.

The polyvinyl acetate composition is used to treat the slabs in a similar way: application is carried out sequentially on both sides until the surface stops absorbing the solution, special attention is paid to the ends.

The main difference from the previous method is that forced drying cannot be performed. In addition, the entire complex of work will require at least 7 days, since the film takes quite a long time to form.

To treat plywood to protect it from rotting, it is not necessary to use glue; dispersed compositions based on PVA with the addition of an antiseptic work much better.

Features of the structure

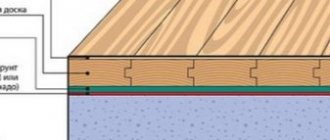

The basis of the plywood production process is gluing thin sheets of wood together so that the natural fibers are directed strictly along or across the long side. The number of layers is most often odd, the minimum is 3 sheets.

Bonding is carried out by various means, of which effective water resistance is provided by certain bakelite compositions: varnishes and alcohol-soluble adhesives. The use of water-soluble modifications of Bakelite and all other types of adhesives leads to the fact that the products cannot withstand the action of water vapor. Low water resistance is especially noticeable when using plywood outdoors. In this regard, it is necessary to treat the material with protective compounds.

Preparing for work

The veneer is treated before painting to protect the product from moisture and to obtain an even surface finish. Processing is carried out in the following way:

- Before treating plywood, sheets intended for painting are pre-dried for several days in a dry room at an air temperature of at least 20 degrees.

- Then the base is cleaned and polished with abrasives. If a large area is being prepared for painting, it is recommended to use a grinding machine. For small areas, use fine-grained sandpaper.

- Before coating the veneer with paint, the treated surface is primed with an acrylic composition with a high adhesion index.

The primer, penetrating into the wood structure, prevents drying out, cracking and improves the properties of the surface.

About safety precautions during work

Many people forget and/or neglect basic insurance standards, working without observing their own safety measures, in vain. Some of the products used to treat sheets and protect against moisture are toxic. Have a negative impact on human health.

Therefore, when working, it is necessary to use personal protective equipment, which includes: gloves, goggles and a respirator. The issue of using protective equipment when processing sheets of plywood mounted on the outside of the room is especially relevant. Indeed, in this case, the use of epoxy resin is allowed.

Pasting with fiberglass

This waterproofing of plywood significantly increases the service life of the material. It is produced by applying a special glass fabric to the surface. If such material is not available to you, you can use ordinary gauze. Any of these materials is glued using varnish. The main condition when choosing such a solution is that it should not contain polyester and epoxy components.

Carry out work with fiberglass or gauze in the following sequence:

- Coat the plywood sheet with varnish.

- Let the varnish soak in for 3 hours.

- Apply gauze or fiberglass to the surface.

- Apply varnish to the ends of the sheet.

- Leave to dry for several days.

- When you are sure that the varnish has dried, reapply the varnish to the entire surface of the plywood.

- Dry for a few more days.

Specifics of paint coating and selection of suitable paint

The main thing is to keep the coating in good condition for a long time. Various coloring agents make a good replacement for the materials described above. Before impregnating the plywood for the floor, you need to decide on the paint, you need to consider what the operating conditions of the plywood coating will be. Water-based pigments and paints, especially latex and acrylic, are ideal for interior work other than floor coverings. It is best to cover a floor made of plywood sheets with drying oil and then with some kind of varnish.

The situation is completely different if linoleum installation is planned on plywood. In this case, acrylic-based dyes are best suited for processing glued veneer, because they perfectly protect against moisture and mold. Impregnation of wall and ceiling panels can be done with various quick-drying enamels.

For processing plywood

located on the outside of the building, very often they select either acrylic-based paints or varnish.

How to apply paint correctly:

- preparatory sanding of plywood will provide better protection against dampness;

- the coupling is ensured by treating the glued veneer with a primer layer;

- in order to fill all the microcracks and imperfections present on the surface of the plywood, it is worth making putty;

- excess putty is removed by re-grinding the surface;

- then apply another primer layer;

- As soon as the soil dries, we begin painting the plywood.

All these steps are highly recommended by experienced professionals, as they provide reliable and high-quality coverage, as well as a beautiful appearance.

Processing methods

Processing plywood and protecting it from moisture can be done in several ways. Here are some of them (the most common in everyday life):

- puttying with PVA glue;

- coating with drying oil;

- treatment with nitro paints;

- gluing fiberglass.

Next, we’ll take a closer look at the best way to process plywood and how to do it correctly.

PVA

Protecting plywood from moisture and rot with PVA putty has many advantages. It reliably protects the material from many negative factors. Here are step-by-step instructions on how to complete the protection process:

- Before treating the material to increase moisture resistance, it is placed parallel to the floor and a layer of PVA glue is applied.

- Allow time for the initial layer to be well absorbed, after which it is covered with another layer of PVA.

- Continue the process until glue stains begin to appear on the underside of the sheet.

- The plate is turned over and the impregnation process is repeated.

We recommend: What is glaze for wood: where and how it is used

Related article: Features of choosing and using tung oil

After the work is completed, the slab is laid on a flat surface and allowed to dry under natural conditions. The disadvantages of this process include rather long processing times. Plywood will have to be protected from moisture for 3-4 days.

A similar impregnation can be done using epoxy resin. But this is quite an expensive pleasure and at the same time not harmless to human health. Sheets treated with epoxy resin are used for exterior use only.

Drying oil

Drying oil is the simplest way to impregnate a plywood board from water. Processing is carried out in the following way:

- The solution (oil for plywood) should first be heated to a temperature level of 60C, due to this its penetrating ability increases.

- Then we impregnate the horizontally located sheet with drying oil using a brush.

- After completing the impregnation process on one side, we proceed to the other.

- Be sure to thoroughly coat the ends of the plywood.

- When the first layer is applied, we begin to force-dry it using an iron or hair dryer.

- After drying is completed, we begin the repeated process of applying drying oil and forced drying.

The number of layers may vary. Stop treating with drying oil only when the solution stops being absorbed by the material (the water-repellent effect is fully achieved).

After this treatment, paint or varnish can be applied to the plywood. The question often arises about how to cover plywood on the floor. This method is ideal for this purpose.

Fiberglass

You can also protect plywood with fiberglass, but to do this you need to use waterproof varnishes that do not contain epoxy or polyester resins. The protection technology consists of the following steps:

- The sanded plate is painted with varnish.

- After allowing the applied layer of varnish to dry for about two hours, fiberglass is glued onto the surface of the plywood.

- Re-apply a layer of varnish to the ends of the slab and leave until completely dry.

- The treatment is completed by applying another layer of varnish and drying the impregnated plywood under natural conditions.

Advice! If fiberglass is not available, you can use regular gauze. After it has been painted with varnish, it will reliably protect the material.

Nitropaint

Another way to treat plywood from moisture is with nitro paints. This is especially true when the material will be in direct contact with water, for example, when repairing a boat or arranging a damp room.

Related article: Changing the interior by patination of wooden furniture

Here are instructions for doing the work yourself:

- Initially, it is necessary to sand the surface and cover it with drying oil.

- Allow the drying oil layer to dry completely and apply liquid paint as a primer.

- Apply a layer of nitro paint to the sheets protected with primer.

- We cover the surface of the plywood with a cloth, which at the same time must be impregnated with nitro solvents.

- After drying is completed, it is treated a second time with diluted nitro paint. The resulting moisture-resistant material is even suitable for making a boat.

Important! The last layer of nitro paint is made quite thin. Otherwise, the degree of strength decreases.

Plywood structure

Plywood is a building material consisting of several veneer layers connected to each other. How moisture resistant it is depends on the composition of the glue that binds the layers. Highly resistant to moisture is a material in the production of which bakelite varnish or glue is used. They can withstand direct exposure to water. Thanks to this, the material can be used to make boats and other swimming equipment without performing additional processing. There is only one “but” – the price is too high.

Other materials that are optimal for construction work and furniture manufacturing begin to delaminate and rot when exposed to high humidity. You can increase the protection of plywood from moisture by impregnating it with special substances. It should be noted that some of them cope with their task with dignity.

On video: which plywood is better.

Varnishing and pasting with fiberglass

Another effective method of waterproofing plywood that ensures durability is the application of special fiberglass fabric. In addition to the fiberglass itself, it is allowed to use ordinary gauze. At the same time, varnish is also used in this treatment, as it acts as an adhesive base. It is important to choose the appropriate paint and varnish composition - it should not contain polyesters and epoxy substances.

How to impregnate plywood for moisture resistance?

Why is it not easy to buy moisture-resistant FSF brand, laminated or bakelite plywood? As a rule, such material is more expensive, so it is sold only in bulk and to order. The question of how to impregnate plywood for moisture resistance can be answered using the following processing methods:

- treating plywood with drying oils - impregnation with water-repellent oily compounds (not paints!), forming a greasy film deep in the wood structure, followed by application of varnishes;

- to impregnate plywood, use moisture-proofing primers - the antiseptic contained in the composition prevents the growth of pathogenic mold;

- treatment of plywood with water-repellent agents – application of hydrophobic compounds prevents moisture from entering between the layers of multi-layer plywood material;

- strengthening plywood with reinforcing water-repellent fiberglass - it is necessary to subsequently fix the fibrous glass mass on a sheet of plywood with transparent varnishes.

To treat plywood surfaces, you can use ready-made varnish compositions 6T or 6C, varnishes for flooring, varnishes 4T and 4C for coating (you can use antiseptics like Pinotex, the main thing is that they are suitable for drying oil). It is not recommended to coat plywood surfaces with polymer epoxy hardening and polyester resins instead of drying oil, since they do not match the composition.

Remember that it will not be possible to impregnate plywood to achieve moisture resistance by simply painting it. Layers of paint are susceptible to cracking over time, so limiting contact with moisture cannot be achieved in this way!

Features of processing slabs before laying on the floor

To obtain a high-quality result when installing sheets on a horizontal base, it is necessary to take into account some nuances of applying a protective coating:

- The panels should not have high residual moisture; acclimatization of the material for at least 24 hours is required. It is necessary to ensure ventilation of the sheets, so they are placed horizontally. To do this, wooden blocks are laid between the panels.

- High-quality grinding reduces composition consumption and promotes the formation of a reliable film. The ends should also not have a burr.

- Impregnation is carried out with the most suitable material according to the instructions. Particular attention is paid to the side that will face the base.

After laying the plywood covering on the floor, the surface must be sanded and primed, then covered with several layers of a protective composition, most often it is wax or varnish.

It is taken into account that the processing is carried out after cutting the product into the required size parts.

paints and varnishes

The first way to make plywood moisture-resistant and extend its service life is by varnishing and painting.

Ordinary enamel paint for wood will do this job perfectly; it is easy to apply to the surface and dries fairly quickly at room temperature.

Before you start working with paint, you need to prepare the surface of the plywood sheet; the surface should be even and smooth. This work needs to be divided into several stages, which include:

Before doing this, you need to level the surface and make it smooth.

Coarse sandpaper is suitable for this. To get perfect smoothness, you need to go through a second layer, but with fine-grained sandpaper. This will give the smoothest surface of the plywood sheet necessary for further work.

Then we treat the smooth plywood with a primer. The best solution would be to treat it with an acrylic primer. This will preserve the structure of the plywood and eliminate small cracks.

The next step will be the painting itself. If plywood will be used in places with high humidity, then special attention should be paid to painting. The right solution would be to paint on both sides.

The edges of the plywood need to be carefully treated with paint in 2-3 layers (these are the most problematic areas). If you are going to use plywood in a room where air humidity is within normal limits, then you can paint the plywood on one side, but do not forget about the edges.

You can paint with a roller or brush. If you have a sprayer, then of course it is better to use it. Using a sprayer you can get a better result and in this case the paint will be applied evenly.

And the last step will be varnishing. We apply the varnish to the painted surface, first sanded a little with fine-grained sandpaper.

We thoroughly clean the surface from the dust obtained as a result of grinding and apply diluted varnish.

Main advantages and disadvantages

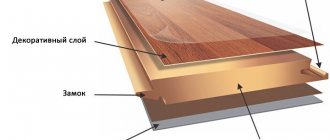

The inner sheets of plywood are made of cheap material, with a large number of knots and defects that do not reduce the strength of the material. The outer sheets, depending on the type of plywood, are made of pine or birch. The sizes of plywood sheets reach 2.5 meters in length and 1.5 meters in width. Finished plywood floors are 5-10 times cheaper than laminate or solid board floors. Such floors can be painted in the color you like and varnished. Or use it as a base for applying 3D cast floors.

Plywood floors over wood floors are less attractive than solid wood, parquet or laminate flooring. But their installation costs tens of times less. Not all types of plywood have high moisture resistance and are used for finishing floors. Finish plywood cannot be leveled by milling, like parquet or solid boards.

The use of plywood for the subfloor binds the logs into a single structure. The floorboard connects the logs only along the installation, with each board secured separately. Therefore, plank floors are more susceptible to squeaks and knocks than plywood floors.