For example, dry decorative plaster is used for interior work and can replace wallpaper. The cost of such mixtures is low, and the article will present the advantages of the materials and methods of their installation.

General idea of dry plaster

In the classic version, leveling mixtures are presented in the form of a ready-made solution. For their preparation, gypsum, cement, lime and solid filler were used. As a rule, it was purified river sand. Today, manufacturers supply ready-made powdered formulations to trading platforms, to which it is enough to add clean water in the amount recommended by the manufacturer. There is information about this on the packaging.

Sheet plaster - what is it? The second version of the finished product is presented in the form of durable solid sheets. Drywall is in greatest demand. These are sheets with a hard core based on gypsum, wrapped in a paper shell.

The latter acts as reinforcement so that the products do not deform during transportation and installation. Additionally, cardboard provides protection against mechanical damage and moisture penetration.

Classification of plaster mixtures by functionality

All compositions can be divided into three large groups. These are standard, decorative, special types of plaster. Each composition has its own characteristics.

Standard plaster

Standard plaster is designed to level surfaces for subsequent application of thin-layer finishing. These include cement-sand and gypsum mixtures. Compositions with cement are used for interior work when the wall has a large distortion and many defects. Cement mixtures take a long time to dry. The porosity of the layer and the type of material that can be used for finishing depend on the type of sand. A dried layer of high porosity CPS is suitable for laying ceramic or marble tiles. It will also withstand finishing with heavy natural stone. The main thing is to choose the right adhesive solution. Gypsum types of mixtures are applied to walls that will be painted or covered with wallpaper. The dried surface is smooth. After cleaning, it may look like glass. This is required if plaster is being used for gluing thin wallpaper or for painting with acrylic compounds. Based on their properties, standard putties are divided into types according to methods of protection from external factors:

- Waterproofing. The mixture may include waterproof polymers. With its help, layers are applied that protect the wall from moisture. Waterproofing compounds are used in kitchens and bathrooms to insulate walls that come into contact with water. These are the internal surfaces of pools and wells. To suppress the hydraulic load, polyurethane, acrylic or epoxy resins are added to this type of mixture for plastering a foam block or aerated block. In such cases, mechanical technology for applying plaster is used.

- Soundproof. Acoustic plasters reduce the level of noise that enters the room from the street. In fact, the layer absorbs sound waves. The strongest degree of sound insulation is needed for cinemas, production workshops, sports facilities and concert halls. It is much more comfortable to live in an apartment building when the external walls are well insulated from extraneous sounds. To do this, expanded clay or pumice, vermiculite or slag are added to the plaster.

- Heat-protective. Mixtures are prepared with the addition of foam glass, expanded perlite, expanded polystyrene or verliculite hydromica. “Warm” layers have low weight, but significant volume. The compositions are used for internal or external plastering of aerated concrete blocks, foam blocks, wood and bricks. The use of a high-quality composition will allow you to avoid additional insulation with sheets of mineral wool or expanded polystyrene.

- Universal. Multi-component plasters are considered universal. They perform little by little all the functions. If there are no priorities for protective properties, it is better to use such compositions.

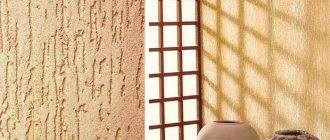

Decorative plaster

Rice. 3. The process of applying decorative plaster This type of material is designed to fill small voids and create a certain visual effect. Textured plasters contain insoluble fractions, with the help of which an intricate relief is created. Structural mixtures do not have such inclusions. They are homogeneous in composition, but their plasticity allows the solution to be laid in intricate ways. Craftsmen use various equipment. They need to be able to use it. Therefore, only experienced plasterers can use structural mixtures. Decorative plasters can be:

- Latex plastic is a plaster used to create visual effects. The finished layer is characterized by increased adhesion and waterproof properties. The composition can be tinted using concentrated types of pastes. After drying, the surfaces can be either smooth or glossy.

- Venetian plasters - contain marble or onyx flour. This is how stone surfaces are imitated. Environmentally friendly material is used for internal processing. The surfaces look noble. They are distinguished by a mirror-like shine and similarity to the cut of natural stones.

- Sea breeze - river sand and pearlescent particles are added to the mixture. The dried layer has excellent adhesion and is resistant to various types of impact. It can be washed without fear of ruining it. Such compositions are used for interior plastering of apartments, offices, restaurants and other commercial premises.

- Sgraphito is a method of applying decorative plaster. The result is the effect of scratched drawings. The colorful, embossed image looks great in large rooms. For such work, a lime-cement mortar filled with stone dust is used.

- Bark beetle - the plaster looks as if the wall from the inside has been eaten by small bugs. Small swollen veins and holes appear on it. The surface looks realistic. The effect is achieved by adding acrylic fillers, silicones or silicates to the mixture.

- Craquelure - looks like a cracked wall. The effect is used to give the room charm and a touch of antiquity. The technology for creating this effect is multi-stage. First, the wall is coated with base paint. Very often it is black. Then water-based varnish and plaster are applied to the dried surface.

- Wet silk - creates the impression that the walls are covered with velvet, silk or satin. Pearlescent shine and absolute smoothness distinguish these surfaces. Each master has his own technique for applying the composition. Therefore, the drawings are always original.

- Marseille wax is a type of plaster with a pronounced relief. Using this technique, textures like wood and natural stone, sandstone and other materials are created. A special feature of the application method is the finishing coating, which gives the relief contrast.

Decorative plasters should not be confused with putty. These mixtures differ radically in composition and purpose. The putty is quickly applied and dries within a few hours. Some types of decorative plaster take days or weeks to dry. The layer can be very thick (up to 7cm). The putty is applied in a thin layer (up to 3mm). The plaster is used to level the bevels, and the putty is designed to smooth the base before applying the finishing coat.

Special plaster

There are types of mixtures that perform specific tasks. Such compositions are called special. X-ray protective mixtures are used for plastering in industrial premises with specific production. This type of mixture includes berite concentrate. The layer thickness is at least 5cm. If this is not enough protection, the wall is covered with berite plates. In production workshops where aggressive chemicals are used, the walls are covered with acid-resistant plasters. These mixtures are also applied in thick layers.

If you are going to finish a concrete ceiling using plasterboard, then first you need to nail the frame to it using dowels and wooden boards. In performing this work, it is necessary to correctly determine the dimensions of the frame that should be mounted. This must be done in such a way that at the junction of the plaster sheets the width of the wooden slats of the frame is at least seven centimeters. But in this case we are talking about concrete. And this material cannot be pierced with ordinary nails. It should be drilled.

A building material such as dry plaster mixture is also commonly called plasterboard. It is used for interior decoration. Drywall is an inexpensive material, and it is simply irreplaceable for leveling walls or ceilings. In this article, together with the Beton-Area.com portal, we will try to talk about what dry plaster is.

What is dry plaster

Dry plaster is sheets of gypsum that are lined on both sides. That's why it's called drywall. This material is used for finishing the facade of buildings, but for interior finishing work it is indispensable. Using dry plaster, you can level uneven ceilings, floors and walls. Dry plaster is also used for further finishing of finished residential premises. Dry plaster for interior work is a modern finishing material. Therefore, it’s worth looking at its photo and seeing what a similar finishing material looks like. If we talk about sizes, then drywall or dry plaster generally has the following dimensions:

- length is from 2 to 3 m,

- width within 1.3 and 1.4 m,

- sheet thickness is 12 mm.

Thus, dry plaster comes in large sheets. And thanks to the large size, you can very quickly finish the interior walls of the room. The result is high-quality and inexpensive work.

Dry plastering of various surfaces

Dry plaster for interior work in the form of sheets is installed using various methods. Their choice, as a rule, directly depends on the surface that needs to be finished. For example, sheets of plaster are mounted to a surface made of brick or concrete using a special mastic, and to a wooden surface they are easily nailed with nails with a wide head. If you are planning to finish a concrete ceiling using plasterboard, then first you need to nail it to It has a frame using dowels and wooden boards. In performing this work, it is necessary to correctly determine the dimensions of the frame that should be mounted. This must be done in such a way that at the junction of the plaster sheets the width of the wooden slats of the frame is at least seven centimeters. But in this case we are talking about concrete. And this material cannot be pierced with ordinary nails. It should be drilled. In our case, first we make holes using a drill for nails of the diameter we need and insert plugs made of wood (or plastic) into them, and then hammer nails into the holes approximately half a meter from each other. If the concrete is very hard, you may need a hammer drill (professional drill). But you need to take into account in advance the fact that the drywall is not mounted tightly to the frame, but so that there is a small space left between the sheets of plaster (about 4 mm) so that the seams can be finished in the future. Based on this, to improve the thermal insulation in the room, you should leave a space of 3 cm in width between the sheets of dry plaster and the ceiling. But installing sheets of plaster to the ceiling (especially if it is concrete) is very difficult and troublesome. To carry out this work, you need a lot of time and some experience, and you also need to use construction tools.

An easier way is to glue sheets of dry plaster to the ceiling using mastic. It can be purchased at a specialized store that sells building materials. This mixture resembles dough, which contains gypsum and a two percent solution of bone glue. It is used so that it does not dry out or harden during its application. When installing sheets of plaster to the ceiling, the mastic must be spread with a spatula on their surface, as small tubercles along the center of the sheet. The distance from each other should be approximately 35-40 cm, and apply mastic in continuous strips along the edges of the sheet. After you have applied a sheet of plasterboard with mastic to the ceiling surface, you should press it firmly and tap on the places where mastic was applied , for its even distribution under the sheet, so that it fits more tightly to the ceiling. After the installation of sheets of dry plaster is completed, time is given for it to dry. The next step is to fill the seams between the sheets with a special gypsum mixture. We can note that by installing sheets of plaster to the surface of the ceiling, you can easily gain free space from the room. And this method is very necessary for small apartments. After installation, the plasterboard sheets are covered with any paint, and the walls are covered with wallpaper. Before pasting the ceiling with dry plaster, the heads of the nails must be painted with varnish or enamel to prevent rust from appearing on them. You can also wallpaper a ceiling previously finished with dry plaster. But, a better option is to paint the ceiling with several layers of oil paint or whitewash it with a water-based composition. In this case, it is better to exclude lime emulsion, since it has poor adhesion to drywall.

Advantages of dry plaster (plasterboard)

The main advantage of dry plaster is its low thermal conductivity and excellent sound insulation properties. It should also be noted that this material has fire-resistant qualities. It is quite resistant to very high temperatures and fire. Drywall is an environmentally friendly material. It does not contain toxic substances. And, as a rule, it does not emit any odors and is widely used in decorating children's bedrooms. Dry plaster is a breathable material. It can also control indoor humidity. If high humidity prevails in your room, then this material will easily absorb it. There is another advantage of dry plaster. This is an opportunity to carry out interior finishing work cheaply and at the same time quite high quality. Moreover, it is possible to establish communications between walls and sheets of plasterboard without any particular difficulties. But there is also a drawback to this material. Drywall is very unstable to increased dampness and humidity. It cannot be used for external decoration of building facades. If dry plaster is constantly exposed to moisture, it will deteriorate - the cardboard will begin to peel off from the gypsum base. Therefore, to avoid this situation, you should take care of this in advance. Paint the drywall with paint containing casein glue as a base. But there is no need to rush into doing this work too much. Following the established rules, before painting drywall or wallpapering, you must begin these actions no earlier than three days after finishing the cladding work. It is necessary to constantly monitor the humidity level in this room in which finishing work was carried out using plasterboard. And then you can enjoy your comfort for a long time.

Conclusions Now you have learned what dry decorative plaster for interior work is. Here we have described the advantages of this material and indicated that the price of dry plaster can be very favorable. Therefore, if you don’t know what material to choose for finishing, then you should pay attention to dry plaster, which will allow all work to be completed efficiently and quickly.

Pros and cons of sheet material

Leveling sheets are used in construction without adding water or other solvents. This allows you to calculate the total weight of the structures being erected, as well as the load exerted on the base, before installation. This will allow you to think through the situation in advance with strengthening the support part, if necessary.

From the point of view of carrying out repair work, craftsmen note the following advantages of the material:

- simple cutting and processing (it is enough to have a construction knife with replaceable blades on hand);

- easy calculation of expenses (there are practically no leftovers, since surpluses can also be used);

- short period of time for covering walls and ceilings (no technological break is required to gain strength of the leveling layer).

The dimensions of dry plaster depend on the purpose of the paintings. The thickness is 0.65-1.25 mm, the height is 2.5-2.7 meters, and the width is usually 1.2 m.

Also, using plasterboard simplifies the process of laying hidden utilities: electricity, plumbing, ventilation. In the case of installing a support sheathing, it becomes possible to provide additional thermal and acoustic insulation.

The disadvantages mainly include the fragility and low load-bearing capacity of the material. This does not apply to the canvas as a whole, but to the local use of the coating for hanging household appliances on it. For heavy devices, it is necessary to strengthen the frame under gypsum board or form seats on a rough base. The sheet itself crumbles easily in the places where the fasteners are immersed.

Finishing technology

To obtain the highest quality and durable finish, you should follow the application technology and adhere to the basic rules of the work.

Installation of sheet dry plaster can be done as follows:

- nail or fasten the sheets with self-tapping screws if there is a wooden surface of the walls or ceiling, maintaining a gap around the perimeter of 1.5-2 mm;

- install on a wooden sheathing or frame base made of galvanized profiles.

The step-by-step technology for finishing indoor surfaces with dry plaster mixtures is as follows:

- Cleaning the surface from dirt, dust and delamination.

- Elimination of protrusions and elements that interfere with operation.

- Protection of metal parts from corrosion.

- Treatment of surfaces based on silicate and ceramic bricks, aerated concrete, gypsum sheets with the Grundir-mittel primer. Concrete base, cement plaster, foam concrete, expanded polystyrene, plasterboard sheathing must be treated with Betokontakt primer.

- Installation of beacon profiles.

- Installation of protective corner profiles.

- Preparation of plaster mortar.

- Applying plaster mortar.

- Leveling the surface.

- Grouting and smoothing the surface.

Installation methods

There are only two ways to fix drywall: frameless or lathing. The method is selected depending on the general condition of the rough wall or ceiling. The list of tasks pursued by the master is also considered: carrying out insulation work, laying communications, camouflaging architectural elements.

Frameless

The supporting lathing is excluded when only surface leveling is pursued. In this case, the base has minimal deviations relative to the plane.

More often, this method is relevant in the case of an old foundation, where the walls need restoration and strengthening. The use of plasterboard allows you to reduce the time required for restoration work and reduce costs.

To fix plaster sheets, it is permissible to use various materials:

- Hardware. A hole is drilled in the base and a dowel is inserted into it under the self-tapping screw.

- Solution. There are specialized mixtures and various adhesives for attaching rigid sheets to walls. Plaster is less commonly used for finishing mineral substrates. When peeled off, the result is less durable, so this approach is acceptable for small areas that will be minimally exposed to mechanical loads. For example, these could be slopes.

- Polyurethane foam. It is better to use foam glue. The main thing here is that the action of the material is aimed at filling voids, and not at expanding. Then the risk of sheets bursting will be reduced to zero.

The first option is good in the case of fragile previously plastered walls with wooden sheathing. The other two are more relevant for stronger foundations, since additional load will be exerted due to the solutions. There is a risk of sheets of dry plaster peeling off, especially with heavy cladding (tiles, porcelain tiles, artificial stone).

Frame

To cover walls with plasterboard, a support frame is required. The canvas is considered a durable material, so it is planned to dismantle it after a long time. Based on this, the sheathing must match or exceed the service life of the leveling finish.

It is permissible to use wooden beams if they are dry and impregnated with special antiseptics. A more practical alternative is metal profiles made of galvanized steel. They are stronger, last longer, cope with loads better, are inert to biological and chemical reagents, and do not burn.

The frame method of fastening takes longer and is more expensive. But there are more advantages here than with the first method. It is possible to finish any structures without the use of temporary supports. It is permissible to change architectural forms, create partitions, hide communications and beams.

Calculation of material quantity

On any packaging with factory-made dry plaster, manufacturers indicate the approximate consumption of the mixture ready for work per 1 m². To determine the consumption of the dry composition, subtract the volume of water that was used for its preparation from the total amount of finished plaster mixture consumed.

The approximate consumption of the finished mixture when using plaster from the most popular manufacturers is as follows:

- cement plaster “CT-24” - about 1.2 kg/m²;

- gypsum plaster composition "NR-Start" from "KNAUF" - approximately 1.60 kg/m²;

- decorative plaster - at least 1.50 kg/m²;

- heat-protective plaster - at least 1.50 kg/m².

Sheet material is calculated depending on the size of the sheet and the total area of the surface to be finished.

To obtain the highest quality and durable finish, you should follow the application technology and adhere to the basic rules of work.

Types of factory mixtures

Powdered mixtures are the product that must be used for leveling mortar. Mix the composition of the dry plaster mass by adding water in the proportions specified by the manufacturer. It is recommended to bring the mixture to a homogeneous state using a construction mixer. It is often necessary to re-mix after a few minutes. This time is necessary for the binder to dissolve better in water.

Plaster

Gypsum is a product of natural origin. It is characterized by good water absorption and rapid hardening. The dry residue has high strength.

It is possible to provoke the formation of rust on metal objects.

Dry plaster mixture is used for interior work. It is recommended to level walls and ceilings in heated rooms with low levels of relative humidity. The solution is mixed in small portions, since the working time of the mass is about 15-20 minutes.

Limestone

Based on a lime binder, as a rule, two-component plaster is made with the addition of cement. The material is recommended for use inside a building, but it can be applied to facades with a mineral composition. Compared to its plaster counterpart, more time can be used to adjust the layer.

A notable property of the lime mixture is its good adhesion to the surface being treated. Compared to other dry compositions, this relatively inexpensive material retains heat in a room better and has high vapor permeability, which has a positive effect on the microclimate in a house or apartment.

Masters additionally note two points: elasticity and resistance to heat.

However, there are also noticeable disadvantages. These include relatively low strength and moisture resistance.

Cement

The basis of plaster with this binder is also sand. Additionally, to increase plasticity and adhesion, the composition contains functional additives.

According to its properties, the mixture belongs to the group of universal building materials. It is used equally often indoors and outdoors under a wide range of operating temperatures and relative humidity.

The main advantages of cement plaster are moisture resistance and high strength. You can work with the solution for more than an hour, so batches are made as needed immediately in a large container.

Against the background of significant advantages, it is worth noting the noticeable disadvantages of the mixtures. The applied mass dries longer than analogues (1 cm can take over 48 hours, a layer of 8 cm can take about two weeks). It is difficult to level a smooth surface with the composition, since the sand mixture does not have time to contact the base and crumbles.

Purpose and types of plaster

Dry plaster is used for interior work. Its main functions are to level the surface of the walls before finishing work and final finishing if decorative plaster is used.

The sale of such dry mixtures can be in bags and packages from 15 to 50 kg or in sheets ready for use.

Before use, dry mixtures are diluted with water.

There are several types of plasters, which can be found in the table:

| № | Name | Description |

| 1 | Regular | Used to remove imperfections when preparing surfaces for finishing work. |

| 2 | Specialized | It can be sound-absorbing, fire-protecting, etc. It all depends on the additives that are included in it. |

| 3 | Decorative | This type has dyes and other components that allow you to make drawings or a certain texture on the walls. |

All described types are sold in powder form and are classified as dry.

Before use, they will need to be diluted with water, after which they can be applied to the wall. Another type of dry plaster is drywall. There is no need to dilute it in water, since it is produced in sheets and is ready for further use without additional manipulation.

Drywall is exposed to moisture, so if sheets are used for the bathroom, kitchen and other rooms with high humidity, then a moisture-resistant type is used.

Application technology

The dry mixture is poured into a working container, the recommended amount of water is added, and everything is mixed with a mixer until smooth. Minor differences in the surface are filled using a trowel and a façade spatula. To form a large layer, the plastering process includes several steps:

- the foundation is prepared;

- beacons are installed;

- using a ladle or trowel, the surface is sprayed/primed with a solution;

- fill the voids and remove excess mixture using the rule;

- cover the rough finish with a finishing layer using spatulas or trowels.

Often, novice craftsmen make mistakes in relation to cracks, weak areas and the thickness of the leveling layer. It is important to pre-embroider the first ones, hammer them with mortar and secure them with a mesh. The latter must be eliminated so as not to cause a destructive process, the detachment of a new composition. If it is necessary to exceed the plaster layer allowed by the manufacturer, then it is necessary to carry out intermediate reinforcement with fiberglass or metal mesh with cells larger than 5x5 mm.

Which option should you prefer?

The choice of leveling plaster is determined by a number of factors.

If you need to hide a lot of communications, carry out a quick finish, and do not plan to hang heavy objects or household appliances, then it is better to choose drywall. Ceilings with large differences and bases that are weak in terms of strength are also better sheathed.

Mixtures for preparing solutions do not require additional materials. They fill all voids, create a monolithic coating, and have high strength and load-bearing capacity. When the differences are small, it is more profitable and expedient to use powdered formulations.