Choosing paint for the stove

The operating temperature for standard metal paint does not exceed 40-50 ℃, so you cannot paint surfaces that are too hot - it will bubble up, lose its original color and may begin to smoke and smell unpleasant. Therefore, in this case, you need to use only special heat-resistant paint for stoves.

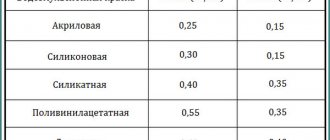

Which of the proposed paint options to choose will depend on the area of its application. Thus, a metal sauna stove can heat up to 600-800 ℃ or more - at the epicenter of combustion the temperature is even higher. But its outer walls may not heat up so much - it all depends on the design. If we are talking about a brick oven, then its surface does not warm up above 200 ℃.

Please note that heat-resistant paint must be suitable for interior use. And for sauna stoves you need paint with moisture protection.

Properties

The performance characteristics of such paint compositions largely depend on the type of varnish or enamel used for their preparation. But there are certain qualities that are equally characteristic of all this type of coloring compounds:

- All of them are capable of creating a barrier effect in the form of a thin, durable film on painted surfaces. It becomes a reliable protective barrier against moisture penetration and other aggressive external influences.

- Aluminum powder dye has reflective properties. This property of reflecting ultraviolet solar radiation helps protect the surfaces of buildings and structures painted with aluminum powder from overheating in hot weather.

- No less significant are the protective qualities of coloring compositions based on aluminum powder. They are not subject to corrosion and lie securely on the surface to be painted, adhering to it.

This dye is sold in the form of metal powder. To obtain the required dye, it must be mixed with the appropriate paint thinner.

There are also ready-made coloring mixtures. The latter are stirred before use and, if necessary, diluted with some solvent to give them the necessary painting consistency. Silver is sold in paint buckets or in jars, as well as in aerosol cans.

Aerosol packaging is very easy to use and store. When using aerosol paints, there is no need for additional painting equipment. Acrylic or other water-based paint compositions are supplied in the same aerosol form.

The greatest demand is for powder coloring compositions for preparing finishing mixtures with your own hands and aerosol packaging. They can have different colors, used when painting small surfaces or used when decorating walls.

A little about the types of heat-resistant paints

Painting very hot surfaces of metal furnaces can only be done with heat-resistant, heat-resistant and fire-resistant paints. But fire retardants are not suitable in this case - they are used for other purposes. When heated to 200 ℃, fire-retardant paint swells and blocks the access of oxygen to the structure, protecting it from destruction in fire. Let's take a closer look at the types of paints.

So, heat-resistant paint for stoves is used at a temperature threshold of 600 ℃. Such compositions are suitable for painting metal elements of stoves and fireplaces, as well as for metal heating appliances. But for sauna stoves they use several different types of materials - heat-resistant enamel, which is designed to heat the surface to 800-1000 ℃.

Fireproof paint for metal products can withstand exposure to open flames. Therefore, its temperature threshold is even higher. However, due to the very high cost, it is not advisable to use such compositions at home.

Another type of paint is high-temperature. Their area of application is painting heating batteries and a number of engine components. As a rule, such compositions are operated under heating conditions no higher than 200 ℃. High-temperature paint for brick stoves can only be used if it is necessary to tint the surface or paint the seams. Metal stoves cannot be painted with it.

For brick stoves, you can also use heat-resistant varnish. Its operating temperature is 250-300℃. After treating the surface with this varnish, it becomes shiny and brighter.

Characteristics and types of aluminum powder

Aluminum powder is divided into pyrotechnic, pigment and dispersed.

- Pyrotechnic powder (PP) is used for the manufacture of pyrotechnic products. Particles of such powder give a lot of sparks and light when burning.

- Pigment powder (PAP) is used to impart a silver color to building paints, enamels, and as a gas-forming substance in the production of concrete.

- Powder dispersed (PAD) is used to make highly durable coatings for steel and pastes used in the production of solar-powered batteries.

How to choose the right one

To choose the right paint for the stove, you need to carefully consider the label, which says what surface it can be used for, for example, heat-resistant paint for metal products. Often this information is printed in large font and is difficult to miss. In cases where the scope of application of paint and varnish products is wide, this is also written on the packaging, but in small print. Be that as it may, such information must be indicated on the packaging, as well as the name of the manufacturer. If this data is not available, there is no need to purchase such a product. It is possible that this is a counterfeit product that may pose a threat to your health.

For metal sauna stoves, use only moisture-resistant compounds, otherwise they will not last long on the surface.

PAP-2

Capable of leafing. When painting, light aluminum plates rise to the surface, partially overlapping each other. This ensures good adhesion to any metal and concrete structures.

Other salient features:

- particle content - from 82 to 92%;

- density - 0.15-0.3 g/cm3;

- residue on sieves - up to 0.3%.

Important for almost all industries. It is used for the preparation of heat-resistant painting compositions with increased strength that can withstand corrosion processes of any complexity. It is characterized by a high combustion temperature, therefore it is suitable for the manufacture of gunpowder, fireworks, and explosive packages. It is used to create self-leveling roofs, providing good reflective qualities. It is also used to produce heat-resistant bricks.

The most common method of sale is in the form of BT-177, called silver. AP significantly increases the heat resistance of the final coating material. Therefore, it is used to obtain high-quality enamel by mixing it with heat-resistant varnishes. Area of application: construction and chemical industry.

In addition, it is in demand as a gas generator for cellular concrete. Its gas-forming properties are higher than those of AP-1 due to its finely dispersed structure.

Packaging

You can purchase heat-resistant paints in various packaging - these can be spray cans or jars. From cans, paint is simply sprayed over the surface, and from a can, paint is used with brushes, rollers or special sprayers.

The volume of the cylinder is usually 500 ml. Cans are produced in 400 g, 800 g, 2.5 kg and 5 kg. There are also large buckets of 5-15 kg and barrels.

Exactly how to apply thermal paint is everyone’s personal choice. For some, it will be more convenient to use a brush or roller, while others will opt for a spray can. In the latter case, the material consumption will be significantly lower, and the paint will apply more evenly and evenly.

Advantages and disadvantages

minimum costs for the purchase of paints and varnishes;

liquid paint in an aerosol can or factory jar is ready for use;

creates a decorative silver coating;

after drying, it forms a durable, hard, moisture-resistant film;

sets quickly;

lays on any pre-prepared base;

the suspension can be made independently from simple and affordable materials.

dry powder is flammable and explosive material;

if powder gets into the respiratory system, health problems may occur;

the suspension has a toxic composition;

not used for painting galvanized products.

Which fireproof paint to choose for the stove

Paint for metal stoves must be selected with a temperature threshold of 600 ℃ or more. Here are a few of the most famous brands with a brief description of each.

Heat-resistant enamel of the CERTA brand, produced by the domestic manufacturer Spectrum. It is designed for use in the temperature range of 65-900 ℃, and its application can be carried out even in frosty temperatures of -30 ℃. The consumer is offered a total of 26 shades of paint, including turquoise, blue and yellow. True, not all colors withstand equally high temperatures. Thus, the most heat-resistant color is black (up to 900 ℃). Behind it are white, gold, brown, copper, red-brown, green, blue, cyan and turquoise (all of them can withstand up to 750 ℃).

All other shades can be used at temperatures not exceeding 400-500 ℃. This paint is produced in cylinders, cans and buckets of various sizes.

Termal paint from the Finnish manufacturer Tikkurila. It is made on the basis of alkyd resins and is available in black and silver. It is able to withstand the heating of the metal at the stage when it turns red. When using this paint on sauna stoves, it does not crack or peel for about 3 years. Please note that if you heat the painted surface to 230℃, it will dry in 1 hour. This is a prerequisite for its polymerization.

Hansa brand heat-resistant metal stove paint comes in 16 colors and can be used in temperatures up to 800℃ to paint stainless steel. It goes on sale in barrels, cans and cans.

Heat-resistant paint of the Kudo brand, produced in Russia, is a silicone enamel for metal products. It is designed to heat the surface up to 600 ℃ and is available in 20 shades, including white, black, red and silver. Sold in 520 ml bottles.

Aerosol paint Bosny. Available in two versions - for heating up to 650 ℃ and up to 200 ℃. It fits well, does not change color for a long time and does not crack. This brand of thermal paint is used for painting metal, plastic, ceramics and glass, wood and fabrics. Pay attention to this brand, since glass paint is rare to find. The container capacity is 400 ml.

Hammerite brand heat-resistant metal paint has one feature. It can even be applied over rust without first cleaning the surface. However, beware of its contact with diesel fuel, gasoline and grease.

The paint can withstand heating up to 600 ℃ and is available in 250 ml cans. It is applied with a brush.

Anti-corrosion heat-resistant ELCON enamel can withstand temperatures up to 800 ℃, including sudden changes. Used for painting concrete, brick and metal. Available in cans in a large number of colors. There is also an aerosol version of ELCON paint in 520 ml cans - it is designed to heat up to 700 ℃.

Paint for metal and other surfaces KO-8111 “Termika” can withstand up to 600 ℃. In addition, it has a protective effect against stray currents, salts, chlorine, solutions, oils and aggressive substances. Used for painting fireplaces and stoves. In baths, it is better to use the KO-8101 brand and KO-8104 primer from the same manufacturer. In addition to heat resistance, this paint is also moisture resistant.

Rust-Oleum heat-resistant paint is designed for very high heat - up to 1093 ℃. In addition, it protects against gasoline and oils. Release form: aerosol can. It comes in matte white, gray, black and transparent.

All of the above options are successfully used for painting brick and metal heating stoves and boilers. And some are also suitable for sauna stoves.

Finished products

Manufacturers offer a choice of 2 options for finished silver paint. The classic version is intended for painting cold and warm surfaces made of metal, wood and minerals (concrete, stone, brick and ceramics). The heat-resistant material is suitable for working with structures that are operated at temperatures up to +400 degrees Celsius.

Ready-to-use heat-resistant paint Source gidpokraske.ru

These can be heating communications and devices, stone units, parts and mechanisms that are subject to heating.

Tip 1: How to breed silverfish

Sometimes the surface can be coated with rust converters, but this must be indicated on the paint package. Upon completion of treatment, the surface must be washed and dried. Rust must be removed completely, down to the smallest specks.

In each case, the required number of paint layers and their direction are purely individual. If more than one layer is required, they are applied in different directions so that the paint goes on more evenly.

The temperature and drying conditions of the paint, as well as the gap between application of layers, are always indicated on the label. Following the manufacturer's recommendations will allow you to obtain a coating that will last the specified period.

Application technology

The preparatory stage involves working with the foundation. Foci of biological damage are cleaned and treated with protective antiseptic agents. Rust, old coating and dirt are removed. Additionally, the surface must be polished with abrasive materials to level and roughen the base. Next, shavings, dust, debris are swept away and 2 layers of soil are applied. The product is selected in accordance with the composition of the object, its porosity and temperature.

Spray painting Source 3dtoday.ru

Serebryanka, regardless of the house or street, dries within a short period of time. Therefore, paint must also be applied quickly. To control the durability of the coating, it is recommended to apply the solution in 2-3 layers.

You can see a non-standard solution for painting a photo frame with aluminum powder in the video: