Preparing the wall

An important stage that should not be neglected. This will help you understand exactly where each decorative element will be located. If there are deformations (cracks, potholes) at the intended installation site, then it is worth repairing them. Proper preparation will ensure high adhesion and prevent peeling of the decor.

The cement mortar fits perfectly on a rough surface. A smooth coating does not provide good adhesion to the components of the cement mixture, so it gradually slides down. Even if you slow down the process, the bas-relief may fall off in the future.

You can solve this problem with the help of an angle grinder. After putting on safety glasses and outlining the outline of the intended decor, you need to walk the grinder around the inner space of the outline. Small frequent notches will increase adhesion and prevent deformation of decorative elements. The cuts do not have to be deep; light, frequent cuts are sufficient.

Some features of using decorative plaster for concrete

Both microcement and microconcrete are mainly used in minimalist design styles, which include loft and hi-tech. When decorating walls in such design directions, a variety of different colors are not provided. They are precisely replaced with plain cold colors that can visually expand the space.

Bright white and red spots on a gray cement background are a very original solution for decorating a room.

Eye-catching accents in interiors made in these styles can be some textiles, plastic or leather items that have bright shades that stand out sharply against a gray background.

Using one of the types of decorative plaster for concrete, it is possible to create various effects - this is an imitation of fresh or old concrete, untreated or rusty, as well as wet facade finishing.

Decorative plaster with various backgrounds of “mountain ranges” and “gorges” of the created relief

In addition, if you want to add additional decorativeness to the finish, you can add the selected color to the ready-made cement or concrete mixtures. Another option for adding an aesthetic touch to the decoration is to paint the protruding or recessed parts of the relief pattern created on the wall.

It would seem like just a concrete wall surface. But the original, deliberately sloppy relief immediately brings a special “zest” to the design of the room. Moreover, if it is combined with other decorative interior details

When creating a shallow relief pattern using this material, it becomes possible to reproduce unique textures using a variety of techniques. In addition, the materials are produced in a wide range of shades of gray and other colors, which also expands the range of its use in decorating the premises of a house or apartment.

Microconcrete can be polished to perfect smoothness, to the point that it feels like silk to the touch

.

Due to the fact that the viability of the finished mixture is quite high, it becomes possible to calmly create a relief in accordance with the developed sketch. The long-term plasticity of the mass also allows you to create wall drawings using polyurethane stencils.

WHAT COLOR OF CONCRETE TO CHOOSE? KITCHEN UNDER CONCRETE

The popularity of concrete walls means that manufacturers offer numerous colors and patterns of concrete. You can choose, for example, dark shades, which are used to liven up white kitchens. Dark concrete on the walls is combined with metal and steel accessories and wooden accessories.

People who prefer bright spaces can choose lighter colored concrete , such as grey. The gray shade of concrete is suitable for a pastel kitchen with harsher colors.

| Interior designers advise: modern technology allows you to paint architectural concrete in any color. Special pigments are used to color concrete. In stores you will find not only architectural concrete of different colors, but also with different textures, surfaces and patterns. |

Advantages and disadvantages of formulations

In addition to the advantages of the previously listed types of decorative concrete, there are several more noticeable advantages of this coating.

Decorative concrete for walls has the following positive characteristics:

- working with the material is quite easy, especially if you have instructions and advice from designers at hand - an ideal option for those who decide to do the repairs themselves;

- despite the minimalism and ease of application of such plaster, the end result looks aesthetically pleasing and original;

- Concrete-like plaster can be used to finish concrete, wood, and plasterboard walls;

- such walls go well with any other material in the interior - glass, metal, wood, textiles, leather;

- large scope for creativity - a variety of colors, textures, reliefs and compatibility allows you to create the perfect interior;

- a wall with decorative plaster can be painted and varnished;

- in a room whose walls are finished with concrete plaster, it becomes much warmer and quieter due to the characteristics of the material;

- Decorative concrete can be used to decorate any room from the inside, and any part of the building from the outside.

Take note: painting the walls to look like concrete will allow you to complement the interior design with bright colors, original drawings, motivating inscriptions, etc.

Concrete plaster - an ideal solution for a residential loft

The disadvantages of this material include:

- high cost;

- the need to use protective equipment when working with it.

Naturally, a significant disadvantage may be the fact that you simply do not like the look of partitions with decorative concrete as a finishing touch. That is why we recommend that you familiarize yourself in advance with photographs of interiors where this material is used.

Varieties

Plastering under concrete involves the use of profile decorative compounds that combine aesthetics, reliability and uniqueness of the finished coating. Cement-based plasters serve these purposes.

Microconcrete

Decorative composite coating based on cement with the addition of resins, fillers and mineral pigments. Suitable for exterior and interior use. It features an absolutely seamless coating. Provides high adhesion to most wall materials:

- concrete;

- drywall;

- tree;

- metal;

- tiles, etc.

We recommend: Elastic plaster for the facade - an elegant solution to a complex of problems

Advantages:

- wide range of textures and colors;

- shockproof, wear-resistant;

- water resistance;

- vapor tightness;

- chemical resistance;

- anti-slip properties;

- absence of construction waste;

- does not increase the load on the structure (layer thickness 2-3 mm);

- environmental friendliness, safety;

- antiseptic properties;

- easy to clean.

Important

The material sets in 30-40 minutes, so you need to work quickly and as a team. A coating of 2-3 layers of protective varnish is required, otherwise the plaster will collapse.

There are five types of material:

- aqua cement;

- microbase;

- microfino;

- microdeck;

- and microstone.

They differ in texture, color and modifying additives. Decorative composition of microconcrete in the photo:

Microcement

Another name for micro concrete. In essence, the materials are no different and have the same characteristics. Finishing with microcement most often includes smooth and thin decorative coatings, which are distinguished by the absence of mineral chips and the presence of polymers in the composition. They are created using the materials aquacement and microfino. Aquacement is resistant to salts and chlorine, therefore it is suitable for finishing bathrooms, restrooms and other rooms with high humidity. Microfino forms a very fine texture and is intended primarily for plastering walls, furniture and ceilings. Microcement decorative composition in the photo:

Characteristics and composition of the material

Any art concrete has high strength. On average, it is 39 MPa 3 days after setting and 59 MPa after 28 days. The whiteness of the finished composition varies between 68-85%, the minimum frost resistance is 100 cycles of freezing and thawing. Art concrete sets quickly and gains strength after 15 hours.

The basic composition of the material is not fundamentally different from classical solutions. Art concrete includes a binder component - Portland cement of white, light gray color M400 or M500 strictly without foreign inclusions and lumps. M600 and M700 cements are used much less frequently for the production of mixtures. The composition also includes quartz sand, which can be partially (up to 5-10%) replaced with granite, marble chips or glass powder.

In addition, art concrete may include other ingredients:

- fine-grained crushed stone, pebbles, shells of a certain shade (to add decorativeness);

- plasticizers, curing regulators, additives to enhance frost resistance, water repellents;

- fiberglass or other reinforcing fibers.

Pigments can be added to the mixture so that it immediately acquires the desired color. Also, purified water in a certain amount is used to prepare the material. In addition to the main binder (cement), art concrete may also include other components with similar properties:

- Acrylic (acrylic resin). The finished material dries quickly, has high elasticity, is easier to tint, and is suitable for rooms with unstable humidity and temperature. The service life of art concrete increases to 10-15 years.

- Minerals - clay, lime, gypsum. They make the composition more decorative, increase abrasion resistance, and provide fire safety.

- Silicates. Provide the highest resistance to damage and chemicals, and repel water. They are used if art concrete is intended for outdoor use.

- Silicone. Gives plasticity, strength, resistance to moisture and ultraviolet radiation.

How to make a concrete wall in the interior: concrete finishing

You can make this finish yourself if you use:

- gray wallpaper;

- decorative plaster with imitation concrete.

The advantage of the latter option is that the surface will be resistant to various mechanical damage, the material is made of environmentally friendly, non-toxic material. You can do this decor yourself if you have experience in finishing work.

A large selection of wallpaper with imitation concrete will suit any room. They can be on a textured or thin basis. The color of the concrete is gray, but the wallpaper can be of different shades. For example, lighter or darker, with a cold bluish tint or with a warm beige tint.

Hue and saturation are selected depending on the size of the room, the selected snowstorm, and the color of other finishing materials. For example, the floor material has a warm shade, then the walls should be made in this color.

In the bathroom

It is not advisable to use wallpaper in the bathroom. Decorative plaster with imitation concrete is suitable here. It must be treated with a special coating, for example, acrylic varnish, which prevents condensation and water droplets from penetrating into the wall.

In the living room

Finishing with plaster or wallpaper that imitates the pattern of a concrete surface would be appropriate here. You can make such decor on just one wall, which will serve as a dominant feature in the interior.

In the bedroom

You can use all types of wallpaper in the bedroom: paper, vinyl, non-woven. Decorative plaster will also look organic here.

In the hall

The hall in a spacious apartment will serve as both a place for receiving guests and a relaxation area for the whole family. For large rooms, textured plasters with an imitation of rough finish are suitable.

In the kitchen

For the kitchen, washable non-woven wallpaper is more suitable. They can be textured or smooth, their main advantage is the ability to remove dirt using wet cleaning.

Art concrete - a new approach to decorative finishing

Despite popular belief, this term does not mean the type of finishing material, but the type of application. Art concrete is a decorative plaster used to create a visual effect: freshly poured formwork, mortar leaks, etc. The base material (one-component) can be almost anything: acrylic, lime.

Manufacturers of finishing materials add special additives to the dry mixture to impart certain properties (elasticity, rapid hardening and strength). Art concrete in the interior looks stylish, of course, provided that the application is carried out by a professional. When applied, one of the following textures is formed:

- mud hut;

- fan effect;

- holes;

- strokes.

In fact, to create a unique and beautiful texture, a finisher should be a bit of an artist, painting a unique picture. Art concrete is applied in 1-2 layers. The hardened surface is protected from above by impregnation.

If desired, the top layer can be made matte or shiny. The surface hardens completely after 3 days. After this, you can carry out wet cleaning and wash the plaster. For finishing you will need: primer, impregnation, art concrete, which can be purchased on our website expert-deco.ru.

Features and types of material

Few renovations take place without the use of decorative plaster - the high versatility combined with the modern appearance of this material expands the scope of its use.

It is customary to distinguish two main types of decorative concrete:

- Microconcrete is a cement mixture enriched with quartz chips, as well as various polymer additives and dyes. This composition is characterized by increased plasticity, is resistant to elevated temperatures, does not absorb odors, however, microconcrete is quite hygroscopic.

- Microcement. Its composition is a cement-polymer mixture. The fundamental difference is the absence of quartz chips. It is ideal for finishing surfaces made of metal, wood, plastic, and also for applying to ceramic tiles.

Photo in the interior of a country house

The interior of a country house has more opportunities for realizing ideas. A simple fireplace with a concrete cladding will look gorgeous. The contrast of cold and hot will look impressive in the interior of the living room.

The photo shows a living room in the interior of a country house. The niche, finished with concrete panels, is fully utilized, combining a fireplace, a seating area and a place for logs.

With the help of concrete columns or small partitions, you can divide the space into zones without compromising the area, without interfering with natural light.

A minimalist staircase with railings is suitable for both classic and modern interiors.

Types of stamps

Since it is with the help of stamps that printed concrete acquires a unique texture, let us consider their varieties in more detail.

Currently, there are two types of dies for concrete pavement: cast aluminum and made of polyurethane.

Aluminum dies

The aluminum matrix is a massive form with special handles. Using cast aluminum stamps, brick and stone ornaments, various slabs and other relatively simple textures are imitated. The main advantages of aluminum matrices are strength and long service life.

Polyurethane matrices

The manufacturing technology of a polyurethane stamp involves casting on existing materials, the texture of which will be imitated. This method allows you to achieve absolute accuracy in conveying all the nuances characteristic of natural material. The most widespread types of polyurethane matrices are:

- brickwork;

- ship flooring (deck);

- skins;

- old pavement;

- fan;

- masonry.

There are other textures that are widely used in landscape design and landscaping of garden and park areas.

Five reasons to finish concrete surfaces

In fact, it’s not concrete, but the finishing for it

Abroad, finishing walls to look like concrete is becoming more and more fashionable and popular. The question arises, why additionally finish the concrete if such surfaces are used as an independent solution in interior design?

Among the main reasons I would like to mention the following:

- Reduced absorbency of the material.

Concrete, regardless of its type, is a porous material with high moisture absorption capacity. For example, lower an aerated concrete block into a container of water or moisten the wall with water from a spray bottle, and you will see how the surface immediately darkens.

We recommend: How to prepare a mortar for laying a stove; methods for making a masonry mixture yourself

If concrete surfaces in a room with excess air humidity are left open, they will get wet, which, sooner or later, will lead to destruction. The solution to the problem is finishing with hydrophobic materials, which will become a barrier to moisture.

- Strengthening building surfaces.

The mechanical strength of concrete surfaces can be increased by reducing the porosity of the structure. Therefore, building surfaces are additionally treated with materials with high penetrating ability.

Special primers that precede plastering fill the pores and polymerize in them, making the surface harder to a depth of 10 mm.

- Ensuring compatibility with other finishing materials.

No amount of paint and varnish will lay evenly on clean concrete, and the same can be said about gluing wallpaper. In order to ensure high adhesion and compatibility with other finishing materials, concrete surfaces are primed and puttied.

- Insulation of building surfaces.

Concrete walls are cold due to the high thermal conductivity of the material. To make building surfaces less cold, they need to be covered with building materials with a lower degree of thermal conductivity.

- Improved aesthetic perception.

Not everyone likes the look of boring gray walls. That is why concrete surfaces are plastered and painted, lined with slabs or other materials, etc.

Methods for finishing concrete surfaces

For each of the building surfaces, as in the photo, you can choose your own finishing method

Among the methods that can be used for finishing concrete, I note the following options:

- Plastering - allows you not only to level, but also to improve the performance of surfaces (used for finishing walls and ceilings);

- Cladding with decorative materials (imitation brick, natural and artificial stone, ceramic tiles, etc.) is a universal method for finishing walls and floors, both inside and outside buildings;

- Decorative design of concrete floors;

- Laying floor coverings on screed.

Method one - plastering walls and ceilings in the interior

Traditional finishing of concrete walls and ceilings is done using plaster mixtures. The mixtures are applied to the surface, smoothed, sanded if necessary, and then painted or wallpapered.

The choice of finishing materials and the method of their application is determined by the type and composition of the concrete surface:

- For concrete walls and ceilings with small relief, putties are used - special pastes that are applied in a layer no more than 5 mm thick;

- For building surfaces with a relief of more than 5 mm, starting cement-sand mixtures (CSM) with a coarse aggregate fraction are used.

Floor putty

Leveling plastering of floors in new apartments is carried out as follows:

Cleaning the floor from uneven surfaces

- Use the edge of a spatula to remove irregularities;

To prime the floor using a roller on a rod

- A layer of film-forming primer is applied with a roller;

You can use ready-made putties, but their price is higher than the cost of the dry mixture

- The putty is being prepared - the dry mixtures are mixed with water, the finished compositions are kneaded with a spatula to obtain a homogeneous consistency;

This way, not only the leveling of dense concrete can be carried out, but also the interior finishing of a house made of expanded clay concrete blocks

- After the primer has dried, the putty is applied as a leveling layer over the ceiling;

Sanding is performed in a circular motion evenly over the entire surface.

- After drying, the first layer of putty is leveled with a plaster float with a diamond mesh or sandpaper;

The best tool for finishing putty with your own hands is a wide spatula

- Upon completion of grinding, the surface is primed again and a finishing layer of putty is applied on top of the applied primer;

- After the applied layer has dried, it will need to be sanded in the directional light of a spotlight so that even minor irregularities are visible;

- The sanded surface is primed again and after complete drying it is ready for painting.

Wall putty

We always start applying the starting layer from the corner

Leveling walls with putty is done in much the same way as on the ceiling, but much easier and with less labor. Before leveling begins, the degree of curvature of the walls and the intensity of the relief are determined.

The thickness of the layer depends on the angle of inclination of the spatula - the stronger the inclination to the surface, the thicker the applied layer

For these purposes, we apply a plaster rule with a built-in spirit level or at least a wide spatula to the surface. If the surface of the walls in a panel house is made with a level difference of no more than 2-3 mm, we level it with a layer of starting and finishing putty with preliminary surface treatment with Betonokontakt or other primers with similar properties.

The easiest way to evaluate the result of wall leveling is in the light of a bright spotlight

During the application of the starting layer of putty, the surface can be reinforced with fiberglass mesh so that cracks do not form when drying. If the difference in levels is more significant, the wall is leveled along the beacons with the application of a thicker layer of the mixture.

Method two - plastering load-bearing walls outside the house

Plastering a concrete surface begins with applying a contact layer

External plastering of concrete is a popular option for facade finishing. Plastering is performed using two methods:

- Directly along the surface of the load-bearing wall;

- With preliminary installation of thermal insulation materials.

Leveling plastering

A relief is applied to the contact layer with a notched trowel.

When plastering load-bearing walls, not putties, but cement-sand mixtures with the addition of slaked lime are used as a leveling mixture.

The base layer is applied on top of the dried contact layer.

Considering that the concrete slab is characterized by low adhesion, before finishing work the walls are treated with penetrating and film-forming primers.

The main layer is stretched and leveled by the rule

In addition, reinforcing mesh can be placed on the surface to strengthen the finish. This solution is especially relevant when plastering with a thick layer.

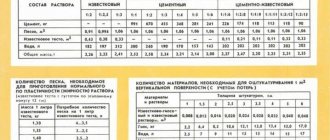

Table of composition of plasters for various surfaces

After the main starting layer has dried, the finishing layer is applied. For final leveling, either additionally screened DSP or putty for external work is used.

In addition to conventional plastering, the purpose of which is to protect walls from the negative effects of environmental factors, there is decorative plastering.

Finishing foam concrete on the outside can be not only reliable, but also beautiful

For example, by adding pebbles to the putty, when grouting the applied layer, you can get a specific scratched pattern, the so-called “bark beetle.” Or, for example, you can outline a layer of laid plaster in the form of finishing masonry and, thus, make an inexpensive imitation of brick.

We recommend: How to putty a car with your own hands before painting

The most attractive result can be achieved by combining decorative plastering with painting work.

Plastering with insulation

Mineral wool slabs or expanded polystyrene slabs are attached to the load-bearing walls, on which plastering is carried out with the laying of a reinforcing mesh.

Mineral wool is fixed to an aerated concrete wall and DSP is applied to it

In some cases, to reduce the thermal conductivity of load-bearing walls, external polystyrene concrete blocks with external decorative finishing are used.

The DSP layer is reinforced with alkali-resistant mesh

The advantage of this method of finishing a concrete facade is the reduction in thermal conductivity and moisture absorption capacity of the walls. But, you need to understand that with this method of finishing, the wall must be insulated not only from the outside, but also from the inside.

Applying the initial layer of DSP over the façade blocks of expanded polystyrene

This point is especially important if work is carried out on building surfaces made of cellular and porous concrete. That is, if the wall is not insulated from the inside, moisture will enter the thickness of the structure, and there will be nowhere for it to escape. As a result, load-bearing walls will freeze in cold weather.

Reinforcement of the initial layer of DSP with fiberglass mesh

Method three - cladding with decorative materials

Cladding a load-bearing wall with imitation brick

This method combines the use of ceramic tiles, imitation brick, natural stone and similar materials. As an example, I propose to consider the cladding of concrete steps with porcelain tiles.

How to finish concrete steps on the street? Of course, porcelain stoneware

The instructions for laying tiles on the steps are as follows:

- All irregularities protruding above the surface level are removed from the steps;

Leveling concrete steps

- After leveling, the concrete surface is thoroughly cleaned of debris and dusted;

- If the steps are inside the building, the surface is treated with Concrete Contact in order to nail down the remaining dust and create an adhesive layer;

Primer for concrete with high penetrating power

- If the steps are outside the building, the concrete is impregnated with Ceresit CT 17 penetrating primer in two passes;

- Using a laser level or using a long rule with a spirit level, we determine the horizontalness and evenness of the surface of the steps;

It is convenient to use a leveled plaster corner as a beacon

- If the level differences are large, beacons are set and the surface is further leveled;

Filling the depression with a cement-sand mixture

The fact that the steps are cast by qualified concrete workers does not guarantee that all surfaces are even. Therefore, it is necessary to timely level out the rubble and relief in order to avoid overuse of glue during installation.

Applying primer before laying tiles

- After the leveling layer on the concrete has completely dried, a layer of primer is applied again, but this time we use Betonokontakt to ensure adhesion;

We pay special attention to laying tiles in the corners

- We lay out the layout on dry concrete, cutting the tiles as necessary and forming a gap between the tiles using plastic liners;

The layout is laid out to try on the tiles in order to cut them to a minimum and save finishing materials. We number the laid tiles immediately so as not to confuse their location later.

- Tile adhesive is mixed;

- Using a comb, glue is applied to the concrete surface, to an area that will be occupied by 2-3 tiles;

We align each tile according to the spirit level

- The tile is laid out on a layer of glue;

- The horizontalness of the masonry is checked with a spirit level, and the tiles, if necessary, are positioned with a rubber mallet;

- After all the steps are lined, you need to wait for the glue to dry completely and only then apply waterproof grout to the tile joint.

Method four - decorative finishing of concrete floors

Stamped painted concrete in the design of a personal plot

Among the methods of decorative finishing of floors, I note the following:

- Coloring (through) concrete before pouring by adding tinting agents to the solution;

- Treatment of concrete with stain (acid- or water-based coloring composition) after achieving grade strength;

- Scoring - making decorative cuts on the floor surface with a circular saw in order to create chaotic or ordered patterns;

- Stamping - used both when finishing the floor and when finishing the base and allows you to apply relief patterns that imitate brick, natural stone, etc.;

- Polishing is a method of processing the finished coating to add shine, used in combination with painting or applying stain;

- A self-leveling polymer floor on top of a concrete base allows you to achieve a perfectly flat, durable surface with the least amount of labor.

Method five - decorating concrete screeds with floor coverings

Linoleum with insulation will make the floor less cold and more attractive

To make the concrete floor less cold, the following floor coverings are laid on top of the screed:

- Linoleum is a flexible, synthetic, or less often natural, inexpensive material with a smooth surface, laid on a heat- and sound-insulating substrate;

- Carpet is a synthetic material made in the form of a woven fabric with a fleecy surface, initially made with an insulating backing;

- Laminate is a multi-layer hard artificial covering that imitates a parquet board, laid on an insulating substrate;

- Parquet board is a multilayer hard natural covering, differs from piece parquet in its larger size;

- Piece parquet is a classic version of floor finishing, consisting of a large number of small planks connected to each other in a tongue-and-groove manner.

Advantages and disadvantages

Modern design involves searching for the best combination of the appearance of the room with maximum practicality. Therefore, kitchens with concrete facades are gaining popularity.

The fashion for loft style elements in the interior dictates the need to search for materials that can embody the severity of forms, convenience, and durability of details that embody the post-industrial world. Concrete facades have a number of advantages over classic materials intended for finishing the dining space.

The main ones are the following properties:

- Strength and wear resistance. The concrete product has a long service life. Kitchen cabinets and countertops are not subject to wear and tear for a long time due to the low deformation rates and brittleness of the compounds included in the substance.

- Choice of shapes and textures. The high plasticity of the material makes it possible to implement non-standard design solutions. Using molds of various sizes, volumes and reliefs, you can cast non-standard kitchen details that will highlight the individuality of its owners.

- Environmentally friendly. The materials consist of natural components, which makes the products safe for humans.

- Price. The cost of concrete is much lower than solid wood or natural stone used for the production of kitchen furniture.

However, such facades have a number of disadvantages that complicate their use for finishing dining rooms and combined work areas for food preparation.

The main negative aspects include:

- Limited choice of finished products. The fashion for concrete kitchens has appeared recently, so even in such a large city as Moscow, buying a set with a similar finish is problematic. Most often, the kit must be ordered, which increases its final cost.

- Low moisture resistance. Concrete deteriorates in high humidity conditions. There is a need for additional processing of products with special substances.

- Limited color scheme and room design. Finishing a kitchen using concrete parts is only suitable for interiors designed in loft, industrialism or Chicago style. Dark shades of the material do not allow creating a bright palette of colors.

- Temperature. Concrete sets should not be installed in rooms with low temperatures. In this case, the cold material does not contribute to maintaining a comfortable microclimate.

Before making a decision in favor of concrete facades, you should think through the interior design as much as possible, create a design project, taking into account the advantages of the material and ways to reduce its disadvantages.

Mixing the solution

Everything here is extremely simple. Prepare a standard cement mortar by mixing together:

- sand - 3-4 parts;

- cement - one part;

- water.

The mixture should be poured with liquid gradually: the thicker the mixture, the stronger it will adhere to the surface. Add water until the solution acquires a thick, uniform structure. There should be no lumps left in the finished substance, as they deteriorate the quality of the cement mortar.

Useful lifehack! By adding a small amount of detergent to the resulting mixture, you can give the composition additional elasticity. This will greatly simplify the application of the mortar on the wall and the formation of a bas-relief along the contour.

Application of art concrete

The material is well suited for interior decoration and cladding of exterior objects. It can be applied to walls and various structures or poured into formwork, matrices, obtaining figures of any type.

Interior

Artistic concrete allows you to create a seamless coating for walls, partitions, columns, ceilings and various architectural elements. Provided that moisture-resistant additives are added or an additional protective coating is applied, it can be used even in the bathroom and other wet areas. Using art concrete, they make cladding with a travertine effect and fill molds for stucco molding, furniture, arches, niches, etc.

Interesting solutions for using the material are:

- panels with three-dimensional decor;

- columns, cornices;

- decorative grilles;

- imitation stone;

- decorations for stairs, etc.

Facade

With the help of beautiful and unusual bas-reliefs made of art concrete, you can provide building facades with an original appearance. Also, the outer walls are covered with concrete to imitate a stone coating. Columns and arches, as well as various figures for decorating buildings, are cast from this material.

Local area

To decorate the territory of your site, you can make yourself or order any figures and sculptures from a specialized workshop. Most often, the following art concrete products are used in home areas:

- flower beds, flowerpots for flowers, shrubs;

- fountains, decorative bridges over mini-reservoirs;

- figurines of animals, fairy-tale characters;

- lamps and fixtures;

- tiles, borders, fences and posts;

- tables, benches, sofas and other outdoor furniture;

- decorative geometric shapes.